BioCycle August 2013, Vol. 54, No. 8, p. 12

Abbotsford, British Columbia: Double Cover At Composting Facility

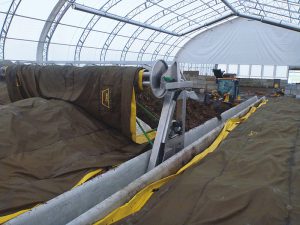

A new composting facility in Abbotsford is receiving approximately 10,000 tons/year organic materials from the City of Abbotsford’s recently implemented source separated organics collection program, which includes yard trimmings, residential food waste and commercial organics from restaurants and grocery stores. Net Zero Waste Abbotsford (NZWA) designed the facility, which it owns and operates. It is permitted for 40,000 tons/year, providing capacity as Abbotsford’s and regional curbside organics collection increases. The program is currently being expanded to include a wide range of businesses, schools and other municipal and agriculturally generated organics. Tipping, shredding and Phase 1 active composting take place within a fully-enclosed fabric building. NZWA utilizes a bunker wall design with GORE® Cover technology. “The regulators preferred we start the process inside under cover to maximize control of the moisture and leachate,” explains Mateo Ocejo, president of NZWA. “One advantage is that employing the GORE technology within the building reduces the emission loading on the biofilter, providing operational cost savings to our facility.” The building uses a 3,000 sq. ft. biofilter, mainly to scrub emissions from the tipping and mixing floor.

Phase 2 of the composting process, which includes curing, maturation, screening and storage, are completed outdoors on a paved surface. “Our master plan for the facility includes a significant demonstration garden and a waste heat energy recapturing system which will pull heat generated during the composting process through an in-slab piping and distribution system,” adds Ocejo. “This system will be used to heat greenhouses and the already in-place farm barns that are located on the same property and were previously used as part of a commercial hog farm.” Compost will be sold for gardening, landscaping, athletic field application and other end uses.

Toronto, Ontario, Canada: Compost Council Of Canada’s Feed The Soil Conference

The Compost Council of Canada’s (CCC) 23rd Annual Conference is September 10-13, 2013 in Toronto. The theme of this year’s event is “Feed The Soil … COMPOST!” Preconference options on September 10 include training courses (one for compost facility operators and the other on odor management) or an all-day “bonus” tour that includes three composting sites and one anaerobic digester. The official conference kicks off on September 11 with tours of two in-vessel facilities, the City of Toronto’s anaerobic digester and the Exhibition Place, an entertainment venue with a number of green initiatives. Conference sessions are September 12-13. To learn more, visit www.compost.org.

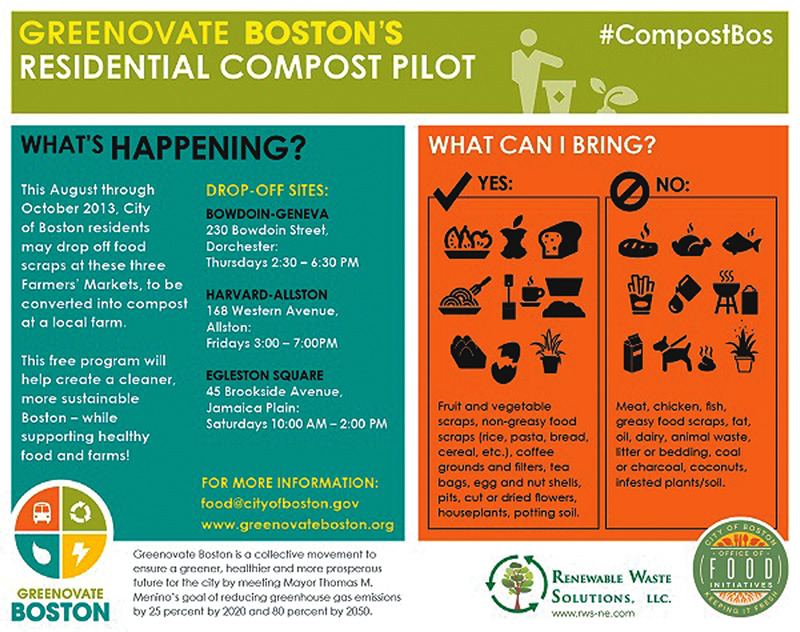

Boston, Massachusetts: Residential Drop Off Composting Pilot

Mayor Thomas M. Menino announced the debut of a pilot program that will allow Boston residents to drop off compostable food scraps for free at three city farmers’ markets: Harvard-Allston, Egleston Square and Bowdoin-Geneva. The pilot is Boston’s first public composting program and was “inspired by feedback during community presentations around the City’s urban agricultural zoning amendment Article 89,” according to the Mayor’s office. It also contributes to the city’s Greenovate Boston initiative, which seeks to educate the public on climate actions like recycling and waste management. “Residents have made it clear that they support a healthier, cleaner Boston that supports local agriculture, healthy food and waste reduction,” Mayor Menino said. “This pilot will show residents how separating food scraps from trash is better for the environment and our bottom-line.” The drop-off sites at the farmers’ markets will accept residential food scraps once a week at specified hours from mid-August through about the end of October. For the three-month duration of this program, Renewable Waste Solutions will donate supplies and hauling services for transport to Rocky Hill Farm in Saugus, Massachusetts, where the collected scraps will be composted.“This pilot will set the stage for a larger conversation about innovative ways to continue increasing recycling in Boston, which is imperative to the vitality of our city,” said Brian Swett, the city’s Chief of Environment and Energy. Acceptable household organics include fruits and vegetables, nongreasy food scraps (e.g., rice, pasta, bread and cereal), coffee grounds and filters, tea bags, egg shells, nutshells and pits, cut and dried flowers and house plants and potted soil. No meat, chicken, fish or dairy are allowed.

Itasca, Illinois: Grocery Chain Grows Food Scraps Diversion

Jewel-Osco, a 176-store grocery chain based in Itasca, has 169 stores within a 70-mile radius in the Chicago area diverting food scraps for composting, according to John Dunsing, project manager. The average store sends between 6 and 7.5 tons/month to composting sites. The annual total for all stores on the program is 12,000 tons. Five haulers transport food scraps from Jewel-Osco stores: Republic/Allied Waste, Waste Management, Veolia USA, Midwest Fiber and Organix. Composting sites in Illinois receiving the material include Nu Earth in Waukegan and Midwest Fiber in Lexington, and three Waste Management facilities in Calumet City, Dekalb and Remeoville. “Each takes similar materials,” says Dunsing. “All of our meat fat and bones go to rendering.”

He first became interested in the concept of food waste recycling in September 2011, when he assumed the role of Jewel-Osco’s environmental sustainability manager. The waste audits were an eye-opener. At a typical store, 60 to 70 percent of the waste was food scraps. “I started rattling the bushes to find anybody we could partner with,” recalls Dunsing. “When I was approaching haulers, I was laughed out of most of their offices. Only a few took me seriously.” Organix was the only company handling source separated organics in the region in late 2011. “Between then and April 2012, we were able to get them to jump on board, with the help of state and local agencies,” he adds. “Quite a few haulers have not been participating, but now local governments are requiring them to offer the service in order to qualify for municipal contracts.”

To get employees up to speed, Jewel-Osco provided in-store training to explain what can go in the 65-gallon wheeled bins (fitted with compostable liners) and how to separate food packaging material, which is also recycled. Providing training to 75 to 80 employees at each store during 2012 was “a very challenging undertaking,” but worth the effort, notes Dunsing. “Once people understood what we were doing and the ‘why’ behind it — that is makes sense for the environment — they really jumped on board and it started snowballing. It has gained great momentum.”

Columbus, Ohio: White Castle Succeeds With Organics Separation

A sign at the counter in the White Castle visited by BioCycle in July proudly states, “Our flowers crave sliders too.”

Raleigh, North Carolina: Annual Vermiculture Conference

North Carolina State University’s 14th Vermiculture Conference is being held October 26-27, 2013 in Raleigh. The event provides the necessary tools and knowledge to start or expand an earthworm and vermicompost production operation. Attendees will learn the latest research on the effects of vermicompost and extracts (tea) on plant growth and disease suppression, how growers are effectively marketing earthworms and vermicompost, and the different technologies being utilized. Other topics to be covered include: Vermicompost application rates and techniques; Extract (tea) preparation, storage and uses; Business strategies; How to harvest and ship earthworms; Greenhouses use of vermicompost; On-site vermicomposting at businesses and institutions; and pathogen minimization. For more information: www.bae.ncsu.edu/bae/workshops/worm_conference.