Ohio Bioproducts Innovation Center leads the charge to commercialize biorefining.

Dennis Hall and Ron Smith

BioCycle September 2013, Vol. 54, No. 9, p. 54

The Sohettes bioindustrial facility near Reims, France incorporates wheat and sugar beet processing, energy cogneration, two bioethanol facilities for biofuel production and a cosmetics plant.

all the coproducts — materials other than the primary intended product — that are generated. In traditional petroleum refining, the early refineries had markets for only a handful of the components from the separation of crude oil. As the industry matured, new products and markets were developed to maximize the profitability of every fraction of the barrel of crude oil, from axle grease to high value monomers for plastics production. This same maturation process has been taking place at advanced ethanol production facilities, where almost all residual materials are effectively marketed as saleable coproducts. But there is a great deal of untapped potential in the bioeconomy, especially regarding use of renewable bioproducts derived from plants, animals, fungi, etc.

all the coproducts — materials other than the primary intended product — that are generated. In traditional petroleum refining, the early refineries had markets for only a handful of the components from the separation of crude oil. As the industry matured, new products and markets were developed to maximize the profitability of every fraction of the barrel of crude oil, from axle grease to high value monomers for plastics production. This same maturation process has been taking place at advanced ethanol production facilities, where almost all residual materials are effectively marketed as saleable coproducts. But there is a great deal of untapped potential in the bioeconomy, especially regarding use of renewable bioproducts derived from plants, animals, fungi, etc.The Ohio Bioproducts Innovation Center (OBIC), located at The Ohio State University (OSU) in Columbus, was created to help tap that potential. OBIC was initially funded through the Ohio Third Frontier, a technology investment program. Since its inception in 2005, OBIC has attracted more than $117 million in grant funding and leveraged over $200 million with industry partners. The vast majority of funding raised goes directly to assist the commercialization of clients’ technologies and services. OSU faculty are involved as needed.

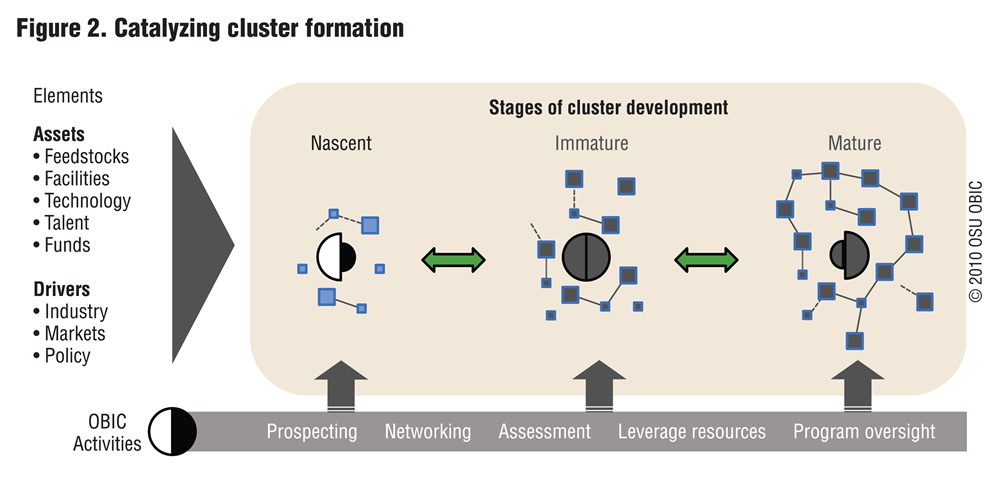

At the heart of OBIC’s unique services is the “Cell to Sell® “Innovation Pipeline, where scalable technology, available feedstocks and market pull are aligned to accelerate bioproduct commercialization (Figure 1). Alliances are formed among business partners into clusters of biobased product sectors; in turn, the clusters become the supply chain and framework for advancing the bioproduct industry (Figure 2). An example is a partnership OBIC has with SWACO (Solid Waste Authority of Central Ohio) and Team Gemini to create an integrated biorefinery using municipal solid waste (MSW) as the source of organic feedstock. The concept is based on a technology center model utilized in Europe. One example is the Sohettes bioindustrial facility near Reims, France that incorporates wheat and sugar beet processing, an energy cogeneration unit, two bioethanol plants for biofuel production, and a cosmetics plant using biobased ingredients. Team Gemini is employing existing technologies that are at commercial scale as well as utilizing OBIC’s Bioproducts Network to collaborate with other companies in this sector, including METabolic Explorer, a manufacturer of fermentation technologies.

Study Tours

For the past two years, OBIC has led a bioproducts study tour of Europe to learn and form collaborative partnerships with the best minds involved in biorefining and bioproducts technologies. These tours illustrate the similarities between U.S. and European interests and expand awareness of the vast growth potential of the bioproducts industry. These tours also highlight the significant potential to take the best technologies and systems from Europe and incorporate those in North America where the potential of biomass feedstocks and biobased markets is tremendous. OBIC encourages industry leaders from across the agricultural, specialty chemical and polymer sectors to help champion development of new bioproducts with like-minded product developers, manufacturers and retailers. For more information about how OBIC can help, go to bioproducts.osu.edu.

Dennis Hall is Interim Director and Ron Smith is Program Director with the Ohio Bioproducts Innovation Center.