Experiment shows viability of using compostable bags to store and transport marine animal waste, thus reducing the biological hazards and other related complications associated with handling this material.

Mark. A. King, Michael Huitt and Michael S. Clark

BioCycle January 2014

Effective management of routine and catastrophic mortalities remains a constant challenge for marine animal rescue facilities. Traditional disposal methods, such as rendering and burial, have been abandoned in recent years, primarily due to rising costs of rendering services and concerns of burials releasing nutrients to groundwater (Geraci and Lounsbury, 2005). Composting offers a cost-effective, environmentally sound disposal alternative that is also protective of public health (Langston et al., 1997). However, for composting to be a viable alternative to disposal, receiving sites must be located close enough to the generating facility to minimize transportation cost, and generating facilities must have adequate storage capacity to allow enough material to build-up to make the transportation run worthwhile.

The storage and transport of marine animal soft tissue also offers challenges, as the material is prone to rapid degradation and release of noxious odors. Additionally, due to the rise of zoonotic diseases, casual handling of this material may pose a biosecurity risk to individuals exposed to the contents. The typical method of handling these materials involves placing the contents into commercial grade nonbiodegradable plastic bags destined for direct burial. Another method stores remains in large unlined totes that are moved to cold storage until time for disposal. At composting facilities, if nonbiodegradable bags are used, they are torn open and the contents are placed into piles. The soiled bags are discarded. When totes are used for temporary storage, cleaning and sanitation of the totes become a concern. Use of a compostable bag/liner offers an opportunity to reduce a biosecurity risk while increasing efficiencies — the bag and contents can be placed directly into the compost pile, temporary storage vessels are free of contamination, and personnel are protected from possible exposure.

Over the last decade, numerous studies have been conducted on the biodegradability of compostable bags with varying successes [Chapman (1999), Kaiser (2001), Foster (2002) and Scott (2008)]. In most cases, bags failed to degrade adequately and often left composters frustrated. The current industry standard, ASTM D6400, requires that a compostable bag must “experience 60 percent biodegradation (by volume) within 180 days.” Mortier (2009) evaluated the degradation rates of several biodegradable plastic bags (averaging 0.79 mil in thickness) in a pilot-scale in-vessel composting system. The recipe included a mixture of carbon amendment and fresh produce and fruit residue. All compostable bags were placed into the mixture and composted over a 12-week period, with periodic manual turnings. During the first four weeks of composting, average vessel temperatures exceeded 122°F. Following the fourth week of composting, none of the original biodegradable plastic bags could be found.

The current study evaluates the relative compost degradation of two commercially available compostable bags: Bio Bag Lawn and Leaf Bags (33 gallon capacity—1.0 mil) and AL-PackCompostable bags (39 gallon capacity—1.1 mil) in a turned pile composting system. All bags were offered as samples directly from the manufacturers. The external packaging for both products states that its product meets the ASTM 6400 compost standard.

Figure 1. Composition of compost piles, during initial building, prior to final covering

Materials and Methods

Beginning October 2, 2013 and ending November 13, 2013, a replicated compostable bag trial was conducted at the University of New England, Marine Animal Rehabilitation and Conservation Program (UNE MARC) Compost Facility located in Biddeford, Maine. On day one, two 5-cubic yard (cy) piles (designated Pile #1 and Pile #2) were constructed using fresh-bedded horse manure (manure) as a carbon source. A mixture of marine animal offal (soft tissues from necropsied marine animals, crabs, Striped Bass bodies, and skates) was added. Each pile was built by first laying out a 24-inch thick by 10-foot square bed of manure. Next, five compostable bags from both manufacturers (a total of 10) were each filled with approximately 50 pounds of the marine animal offal, for a total of 250 pounds per test pile, and carefully placed onto the center of each of the compost beds. Pile #1 contained filled bags from BioBag and Pile #2 contained filled bags from AL-PACK. Each of the beds was then loaded with an additional 150 pounds of loose marine animal offal on top of the bagged product (Figure 1).

Finally, each pile was capped with an additional 36-inch thick layer of manure. Two Reotemp® analog thermometer probes (300 series) were placed into each pile at 1-foot and 3-foot depths, to allow daily monitoring of biological activity near the surface and at the core of each pile. Piles were also monitored daily to check for nuisance odors, leachate generation and to evaluate any vector activity. Each pile was turned, using the facilities’ front-end loader, on a 2-week interval throughout the 6-week study period. At each turn, visual observations were taken to determine the percent bag degradation for each manufacturer.

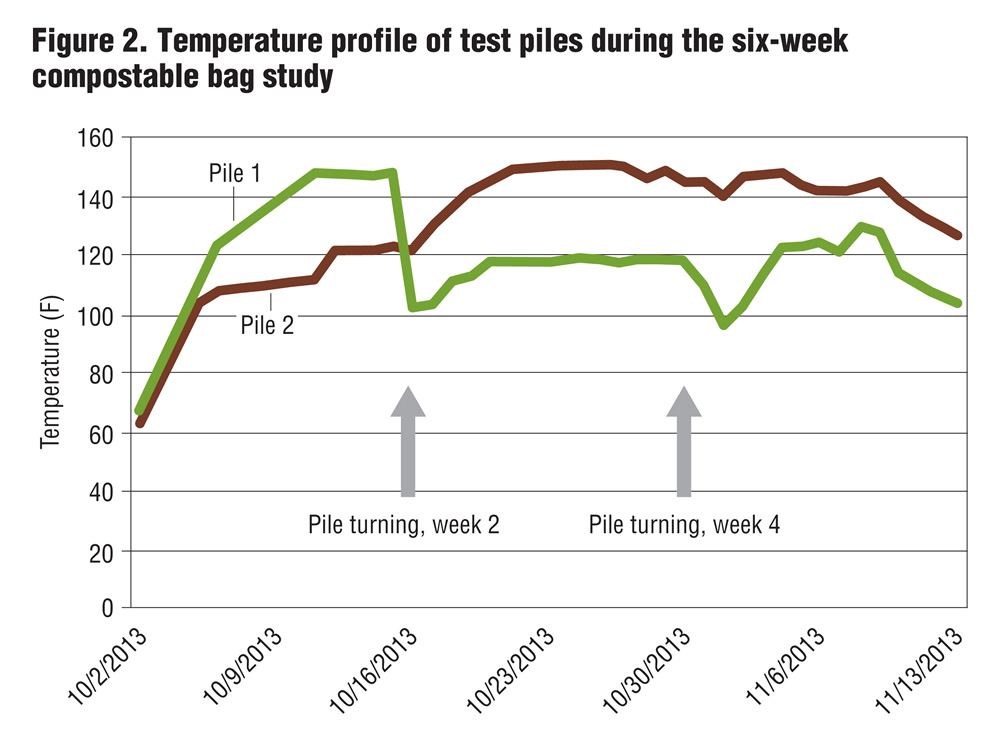

Figure 2. Temperature profile of test piles during the six-week compostable bag study

Results and Discussion

Figure 2 portrays the distribution of temperatures for each of the compost piles during the 6-week study period. Both Pile #1 and Pile #2 achieved thermophilic composting temperatures (in excess of 131°F) during the 6-week study period. It is interesting to note that core temperatures in Pile #1 rose steadily, exceeding 131°F during the first week, whereas in Pile #2, it took a little over two weeks before the core exceeded the 131°F threshold.

However, following each turning event, Pile #1 showed dramatic temperature dips (dropping 20-40°F), whereas Pile #2 maintained a fairly consistent temperature profile irrespective of turning events. Since both piles were built in a similar fashion, this could have been due to the composition of the compost bag parent material or possibly, a “dead spot,” or moisture/texture inconsistency in the horse manure mixture or marine offal material itself. Without more details of the activity within each pile, or the specifics of the composition of the manure, it is not possible to definitively identify the key factor responsible for the temperature differences between the test piles.

Figure 3. Excavated bags following two weeks of composting: Ragged edges seen on both compostable bag samples

Compost bag degradation over the course of the 6-week study was noted and recorded as well. Both bags showed considerable breakdown by Week 2; the material became semitransparent and was easily torn with gentle probing. It was estimated that approximately 25 percent of the material had been degraded (Figure 3).

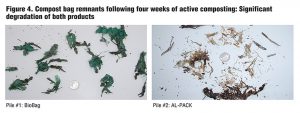

Pile #2, which contained the AL-PACK bags, appeared to have more advanced degradation in both the marine animal offal and with the compost bags themselves. The bag materials in this pile had turned from clear in color to translucent (silver) and shredded into long strands when handled. The higher temperature profile, noted for this pile in Figure 2, represents increased microbial activity levels, and helps to explain the more advanced degradation. By Week 4, it was estimated both compostable bags had degraded greater than 90 percent, represented by remaining small pieces of material with the largest measuring no greater than one to two inches. (Figure 4).

Figure 4. Compost bag remnants following four weeks of active composting: Significant degradation of both products

By Week 6, none of the original compost bag materials could be observed in either pile (Figure 5), and the experiment was concluded. The decision was then made to combine the piles for curing purposes. No odors, leachate, or vector activity was observed during the study.

Figure 5. Bag remnants after six weeks of composting: No signs of original materials remain

Recommendations

Based on the results of this investigation, we found the two brands of compostable bags used in the study will readily degrade in a hot, aerobic composting system. If these brands reflect the current industry standard, then marine animal rescue facilities could be encouraged to purchase and use them on a routine basis, thus reducing the biological hazards and other related complications associated with handling marine animal waste. However, there are other compostable bag designs that could be similarly utilized. Therefore, this investigation should not be taken as being complete and absolute, but merely a verification that some commercially available products do compost when placed in an active composting environment.

The next step is to provide these same compostable bags to the actual marine animal technicians for in-field trials. While substituting the compostable bags for the plastic ones currently in use for storage procedures, we will monitor the viability of the compostable bag design as a means of long-term storage prior to disposition into a compost pile.

Mark. A. King and Michael S. Clark are with the Maine Department of Environmental Protection in Augusta. Michael Huitt is with the University of New England in Biddeford, Maine. The authors wish to thank Nate DiMartino and Zach Towne for their assistance with the study.