First graduate student to work on-site at University of Wisconsin-Oshkosh dry fermentation digester describes feedstock variations and biogas production trends.

Brooke Koenig

BioCycle February 2014

In 2011, the University of Wisconsin (UW)-Oshkosh built the first industrial-scale high solids dry anaerobic digester (AD) in the Americas. The facility receives yard trimmings from the city of Oshkosh and the campus; food waste from the campus as well as grocery stores and restaurants from all across the Midwest; and some farm bedding. Approximately 150 to 200 tons/week of organics are processed. After two years of operation, the UW-Oshkosh dry AD, which uses the BIOFerm technology, has processed nearly 10,000 tons annually of organics, and has produced enough power to meet 8 percent of the University’s overall energy consumption. The thermal energy generated by the 2G Cenergy combined heat and power (CHP) unit is used to heat the plant processes. The potential exists to heat neighboring buildings as well.

In 2011, the University of Wisconsin (UW)-Oshkosh built the first industrial-scale high solids dry anaerobic digester (AD) in the Americas. The facility receives yard trimmings from the city of Oshkosh and the campus; food waste from the campus as well as grocery stores and restaurants from all across the Midwest; and some farm bedding. Approximately 150 to 200 tons/week of organics are processed. After two years of operation, the UW-Oshkosh dry AD, which uses the BIOFerm technology, has processed nearly 10,000 tons annually of organics, and has produced enough power to meet 8 percent of the University’s overall energy consumption. The thermal energy generated by the 2G Cenergy combined heat and power (CHP) unit is used to heat the plant processes. The potential exists to heat neighboring buildings as well.

May food waste (top, left)

May yard trimmings (top, right)

October yard trimmings (bottom, left)

November food waste (bottom, right)

Digestate produced at the UW-Oshkosh is extremely nutrient rich and has many potential uses. It is sent to a composting site where it is placed into windrows and over time turned into a high quality soil amendment. Other possible end uses include drying the digestate to remove the moisture and using the remaining fibrous material as animal bedding.

Because the digester is located in central Wisconsin, the feedstocks are strongly affected by the varying seasons. Food waste in May looks far different in October. The same can be said about yard trimmings. In addition, the seasons affect their availability. Throughout a summer with little precipitation and during the winter months, yard trimmings can become completely unavailable. As the first graduate student at UW-Oshkosh to work on-site at the facility since the start-up phase, I have had a unique opportunity to observe and study various aspects of digester operations. My thesis project has focused on feedstock seasonality, and how these seasonal aspects impact both biogas production as well as biogas quality.

Feedstock Recipes

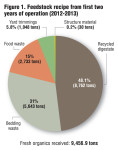

Each week, staff at the UW-Oshkosh digester need to build a recipe based on the feedstocks available. Figure 1 highlights a general recipe and the percentages of each feedstock type used based on a target ratio of 50:50 fresh material to recycled digestate. Because bedding waste is not the optimum feedstock to utilize in high solids dry systems other than for structure, the goal is to displace more bedding by increasing the percentages of food waste or yard trimmings, if possible. During the winter months, however, the digester needs to rely on more deliveries of bedding since yard trimmings are unavailable.

Approximate 150 to 200 tons/week of organic materials are processed in the fermenters (top) at the UW-Oshkosh dry AD facility. Biogas is fed into a 2G Cenergy combined heat and power unit (bottom).

Approximate 150 to 200 tons/week of organic materials are processed in the fermenters (top) at the UW-Oshkosh dry AD facility. Biogas is fed into a 2G Cenergy combined heat and power unit (bottom).[/caption]Data analysis is still in the early stages. However, several graphs have been generated to determine if a correlation begins to present itself, as seen in Figure 2 showing the food waste added to batches in Fermenter 1, one of the four fermentation bays of the digester. By plotting the organic dry matter (oDM) of the food waste, which is a percentage of the dry matter (DM) that consists of only organic material along with a line representing the biogas yield, correlations may begin to present themselves with each individual feedstock.

This process can be repeated for each individual feedstock used in each batch within the individual fermenters. Figures 3 and 4 plot the oDM for yard trimmings and bedding waste, respectively, used in batches in Fermenter 1. Two years of post start-up data will be finished at the conclusion of February 2014, with more advanced statistical analysis to be done on the data collected from the UW-Oshkosh digester, including nonmetric multidimensional scaling, principal component analysis, and canonical correlation analysis, all of which help make sense of cross-covariance matrices. The data used to investigate what aspects of a feedstock recipe influence biogas have many variables affecting biogas, giving rise to the need for multivariate statistics.

Brooke Koenig is completing her graduate studies at the University of Wisconsin-Oshkosh.