Since its grand reopening in November 2012, Silver Springs Organics in Rainier, Washington

has been taking in approximately 190 tons a day of commercial, institutional and residential organics.

Molly Farrell Tucker

BioCycle February 2013, Vol. 54, No. 2, p. 20

Local regulations in Thurston County where the original Silver Springs operation was sited require recycling and composting facilities to operate under a roof to minimize wastewater and odor generation. This meant constructing a very large building, which would have been too expensive for a start-up merchant facility without long-term contracts. Schoenbachler proposed using the ECS AC Composter for the original facility, which uses impermeable covers over the compost piles, as a cost-effective alternative to a roof. In addition to the covers, the system had three major components: automated aeration control and monitoring; a negative-only aeration system; and a biofilter for odor and emission control.

Silver Springs filed for a variance from the Thurston County code on the basis that the AC Composter cover and negative airflow system together could capture and contain the odors and ammonia emitted by the composting process, thereby meeting the code’s intent. All of the process air would also be scrubbed through biofilters. The county granted the variance to build an open-air, covered ASP. Above-ground aeration was utilized instead of a more expensive below-grade aeration floor. “The way the code was written, aeration wasn’t required,” recalls Schoenbachler.

When Silver Springs opened in 2007, it was permitted to process 10,000 tons/month of pre and postconsumer food waste, as well as yard trimmings, wood and agricultural feedstocks. Selling the facility wasn’t in Schoenbachler’s plans when he started. “I wasn’t anticipating selling it,” he says.” “Waste Connections was one of our customers and approached me because they needed additional composting infrastructure as part of their system.” After acquiring Silver Springs, WCI retained all the staff including Schoenbachler, who became site manager.

At the time of the sale, the amount of organics coming into the facility was increasing dramatically, which led to odor problems from the leachate on the paved surfaces and in the pond, and from low oxygen levels within composting materials due to insufficient aeration — attributed to the higher volume being processed. “Some changes in local food and yard waste collection programs created exponential increases that outpaced the infrastructure that was in place,” explains Schoenbachler. “We could have made modest improvements and struggled with the volume threshold, but Waste Connections saw that an overhaul was the best long-term solution.” WCI shut down the facility in August 2011 to undertake major facility improvements. While the facility was closed, the feedstocks were diverted at the source to other composting facilities.

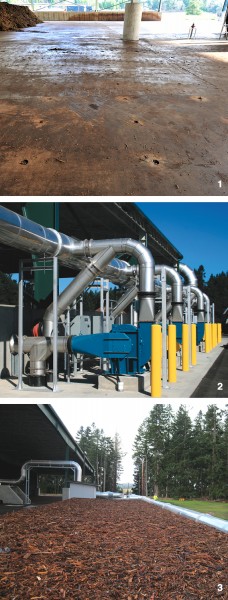

The Stage I composting system features a concrete aeration floor with about 10,000 linear feet of below grade pipe (1). There are 14 independently controlled high aeration zones, each fitted with a 20 hp blower (2). New biofilters were added to handle the negative exhaust air from the Stage I system (3).

Site Improvements

The extensive improvement project was completed in November 2012. A permanent roof was installed over the entire 220,000-square-foot composting area. “Rainier gets 50 to 60 inches of rain annually, so we were at the mercy of the elements without a roof structure,” says John Rodgers, WCI’s Division Vice President, Pacific Northwest Disposal and Organics. “Rainfall formed leachate on the paved surfaces even though the piles had tarps over them.”

The roof and a new grading plan keeps storm water separated from process leachate. The original mixed water containment pond (storm water and leachate) was emptied, cleaned and restored. It is now used to collect rain water from the roof. “With the new roof, there is significantly less leachate so we don’t need the pond anymore,” notes Rodgers. Leachate is collected via a network of drains, the aeration floor, and subgrade piping. The new leachate and condensate collection system conveys leachate to four above-ground storage tanks that have a total capacity of 54,600 gallons. Leachate is recirculated from the tanks back into the composting process for moisture conditioning when necessary.

ECS was again contracted to design and provide components for a new intensive Stage I composting system based on other successful WCI composting facilities. It features a concrete aeration floor with approximately 10,000 linear feet of below grade sparge pipe fitted with 2,700 risers. The floor has 14 independently controlled high aeration rate zones, each fitted with a demand controlled 20 hp blower and motorized dampers that switch between positive and negative aeration (based on established setpoints). New biofilters were added to handle the negative exhaust air from the primary composting system.

Materials Receiving And Composting

The feedstock receiving area, which also features an in-slab aeration system to immediately oxygenate materials as they are tipped, encompasses 22,000 square feet. Feedstocks are transferred from this receiving area to the 54,000-square-foot Stage I composting area. Stage I is a 15-day, “high-rate” composting phase during which materials are turned up to five times with a Vermeer Row Turner and aerated at rates up to 6 cfm/cubic yard. “The system delivers enough aeration force to maintain the piles at 16 to 18 percent oxygen,” says Rodgers.

Materials are then moved to the adjacent 140,000-square-foot Stage II area for further stabilization using the previously installed ECS AC Composter covers and a “CompDogs™” aeration floor system. The material is piled over the inflated CompDogs that form a tunnel in the shape of a Gothic arch. The inflated “tubes” remain under the piles for 12 to 24 hours and are then deflated and removed. The resulting air spaces are connected to the aeration system to provide distributed aeration under the piles. This Stage II area is divided into two 14-zone groups sharing one 60 hp fan per group. One system integrates the control and monitoring of both the Stage I and Stage II areas in a web server based system.

Materials in the 15-day Stage I phase are turned up to five times with a Vermeer row turner and aerated at rates of up to 6 cfm/cy.

Stage II has two phases, each taking 15 days. After the first 15 days, the piles are moved to the back of the facility, where the process is repeated. “After the final 15 days, the material is stable and ready for screening,” says Rodgers. Silver Springs uses a Komp-tech Multi Star L3 for screening and production of final compost. Most of the compost is purchased by wholesalers for topsoil production and some compost sales. “We also have some limited in-house retail sales,” he adds. “At our high volume production, we find that purchase by wholesalers is most advantageous for movement of material into respective markets.”

Silver Springs had its Grand Reopening celebration in September 2012, with operations starting again last November. “We have been taking in approximately 190 tons a day since start-up of the facility and have experienced no significant operational issues,” notes Rodgers. “In fact, the oxygen levels and temperature control in the piles have exceeded our expectations.” He estimates the facility will produce 75,000 to 85,000 tons of compost annually.

“Having Waste Connections acquire and upgrade Silver Springs Organics has been positive for all parties,” concludes Schoenbachler. “It’s a much better program now. There is more infrastructure, including the odor and environmental controls. We now have an extraordinary, state-of-the-art facility. It’s not something that the average small company in today’s economy would have the resources and capital to do.”

Molly Farrell Tucker is a Contributing Editor to BioCycle.