The number of digesters at agricultural operations increased in 2012 — although less than 2 percent of dairy and swine operations in the U.S. have AD systems.

Nora Goldstein

BioCycle September 2013, Vol. 54, No. 9, p. 41

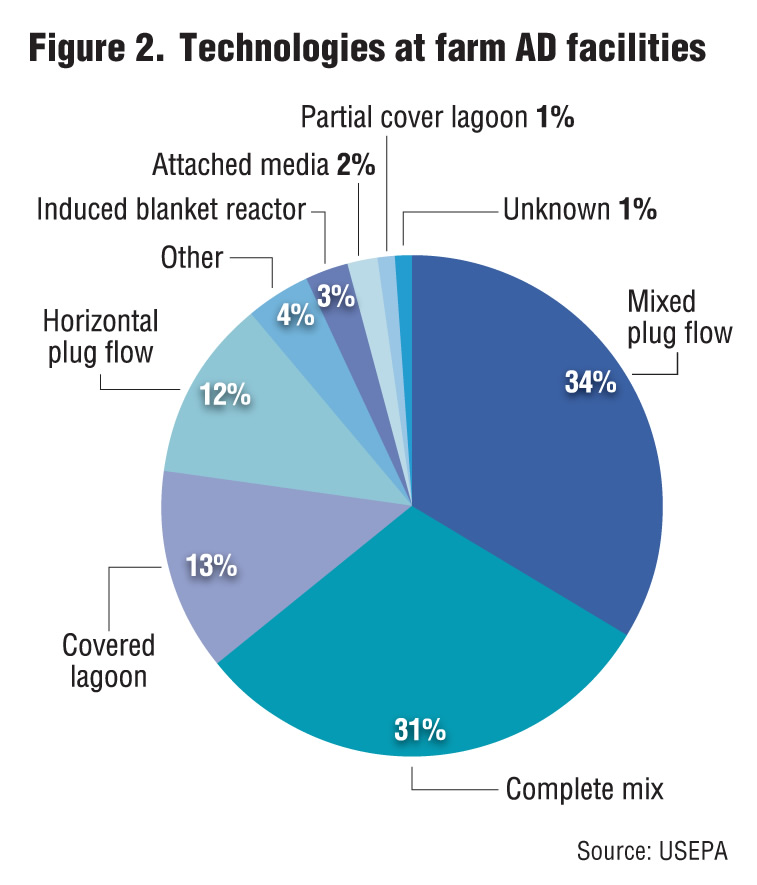

Installation of anaerobic digesters (AD) at dairy, swine and poultry operations in the U.S. has continued to grow at a steady pace. According to the U.S. Environmental Protection Agency’s AgSTAR program, there are 202 farm-based AD facilities in the U.S. (Figure 1), with 20 digesters brought on line in 2012. Of the 202, the dairy sector has the most —167 projects in 27 states — followed by swine with 23 projects in 13 states. Poultry (4 projects in 3 states), beef (3 projects in 3 states) and digesters receiving a mix of livestock manures (5 projects in 4 states) comprise the rest.

The motivations to build a digester still revolve around odor and nutrient management, availability of bedding from the separated digested solids, and energy savings on the farm, notes Allison Costa, program manager of AgSTAR. “But we also are getting more interest in using biogas as a vehicle fuel, especially with the price of gasoline and diesel rising,” she says. “Projects such as Fair Oaks Farm in Indiana, which utilizes biogas produced from their digesters to make compressed natural gas (CNG) for vehicle fuel, show it can be done. It isn’t just an idea anymore.”

AgSTAR’s 2012 data summary also showed that the number of codigestion projects — based on reporting from facilities — has reached 45 percent, up from 40 percent in 2011. “What we see is that a lot of digester projects start up with manure only and then add substrates later on,” explains Costa. “Interestingly, we’ve been getting more inquiries from the solid waste sector, e.g., waste haulers and generators, about what feedstocks farm digesters are accepting. They are trying to identify processors for the organics in the municipal solid waste stream. In turn, we are seeing some agricultural cooperatives getting interested in building digesters to handle that capacity. This is definitely resonating throughout the agricultural industry and causing farmers to be more interested in AD.”

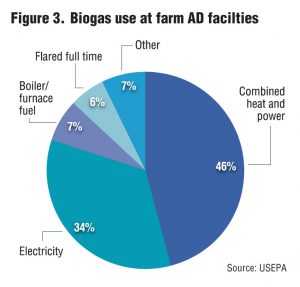

The 2012 data also found that of the 202 operating digesters, 92 use the biogas for combined heat and power (CHP) and 69 utilize it to generate electricity only. Of the 40 remaining projects, the biogas is used for boiler/furnace fuel (7%), flared full time (6%) or utilized in projects combining boiler/furnace fuel, electricity, CNG and pipeline gas (7%) (Figure 3). Biogas end use for most new projects in 2012 is electricity generation (60%). Overall, more than 600 million kWh/year are generated by farm-based AD projects. In 2012, according to the AgSTAR data, 168 electricity projects generated an average of 3.7 million kWh/year each.

With regard to AD by-products, Costa notes a trend toward capturing and capitalizing on the nutrients in digested manure. “We are seeing increased interest in marketing the co-products, especially the nutrients, as prices for electricity have fallen and farms are not generating as much revenue from the energy component of the digester operations.” Solid effluents continue to be used as bedding, especially in regions where the price of wood shavings has increased, as well as for production of potting soil, soil amendments and biodegradable pots.

Climate Benefits

The EPA’s AgSTAR program is housed in the agency’s climate division, along with the Landfill Methane Outreach Program, and the Global Methane Initiative, which works with 42 partner countries and an extensive network of over 1,100 private sector participants to reduce methane emissions. (Costa is currently CoChair of the Initiative’s Agriculture Subcommittee.) In his 2013 Climate Action Plan, President Obama specifically references that anaerobic digesters play a role in reducing methane emissions, noting that “over the last three years, the Environmental Protection Agency and the Department of Agriculture have worked with the dairy industry to increase the adoption of methane digesters through loans, incentives and other assistance.”

EPA’s Air Office recently published the final rulemaking that establishes the volume requirements and associated percentage standards that apply under the agency’s Renewable Fuel Standard 2 (RFS2) program in calendar year 2013 for cellulosic biofuel, biomass-based diesel, advanced biofuel, and total renewable fuel. Digesters qualify for RFS2 RINs under the RFS2 advanced biofuel category. RINs (Renewable Identification Numbers) are tracking numbers assigned to each gallon of qualified renewable fuel under the RFS rules. The standards ensure that transportation fuel sold in the U.S. contains a minimum volume of renewable fuel as required by the Energy Independence and Security Act of 2007. Based on these standards and the 2013 volume requirements, about 10 percent of all fuel used in 2013 will be from renewable sources.

State Initiatives

As part of its scope of services, AgSTAR is involved in outreach and education, as well as creating partnerships with state and regional groups to encourage farm digestion. “We’ve been working with our partners on webinars on specific digester-related issues, as well as connecting people with EPA and USDA programs that may be of interest,” says Costa. “We also track legislative and regulatory developments at the state level. For example, New York State recently adopted amendments to its Part 360 rules that allow agricultural anaerobic digestion facilities meeting certain requirements to accept nonmanure feedstocks for codigestion without requiring a solid waste permit.”

On the West Coast, the California/Federal Dairy Digester Working Group, headed by the California Department of Food and Agriculture, is a multiagency coalition formed in 2011 to reduce barriers to the proliferation of AD projects in California. “The working group is comprised of federal, state and local agencies partitioned into three subgroups to target the biggest challenges to dairy digester development in the state: technology, economics and regulation,” explains Costa. “Although California is the nation’s top dairy-producing state, significant air and water quality issues (nitrous oxide and nitrate pollution, respectively) have led to stringent environmental regulations that make permitting a dairy AD project challenging. The working group has already produced great results, including the presentation of a set of recommendations to the California Governor’s Office, some of which have been implemented.”

Digester Promotion

In May 2012, the U.S. EPA Office of the Chief Financial Officer, in collaboration with other EPA divisions that included AgSTAR, hosted a Technology Market Summit that included a track on biodigesters. In preparation for the Summit, EPA convened a workgroup comprised of both public and private sector representatives to examine barriers to widespread digester implementation and brainstorm solutions to increase digester use in the U.S. The group developed a primer summarizing these barriers and solutions and presenting case studies of successful anaerobic digesters across the biogas sectors. “This workgroup has continued to meet to share information and coordinate activities in support of digester promotion,” says Costa. “The group is currently working on public outreach pieces that describe the digestion process and its benefits in a simple manner and answer the most frequently asked questions about AD.”

As follow-up to the Technology Market Summit, EPA joined a new partnership, established by the Heinz Center for Science, Economics and the Environment, Nicholas Institute for Environmental Policy Solutions (Duke University), American University Center for Environmental Policy and the Environmental Defense Fund. This partnership is a nonbinding, nonlegal, voluntary collaborative committed to accelerating the development, adoption, deployment and export of technologies (including anaerobic digestion) that protect health and the environment as they grow the U.S. economy and create American jobs.

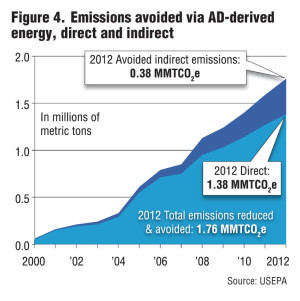

Overall, while AgSTAR’s most recent data highlights an increase in the number of anaerobic digesters at U.S. agricultural operations, the reality is that less than 2 percent of the nation’s dairy and swine operations have operational AD systems. Recently, the Innovation Center for U.S. Dairy and the USDA renewed their Memorandum of Understanding that calls for the dairy industry to reduce its carbon emissions by 25 percent by 2020. The Innovation Center has set a goal of helping to put over 1,000 digesters on U.S. dairy farms in the next 10 years. “AgSTAR has calculated that if all candidate farms installed digesters, the electricity generation potential would exceed 13 million MWh/year, which is enough to power nearly 500,000 average American households,” notes Costa. “In addition, the energy created from biogas generated by agricultural digesters can significantly reduce greenhouse gas pollution and help lessen the risks associated with climate change. And storing manure in anaerobic digesters while it decomposes increases flexibility for the farm to manage the nutrients appropriately, which protects local water quality.”