BioCycle July 2016

Nora Goldstein

The trucks are hooked up to the slow fill system in a line,” explains Doug Button, president of South San Francisco Scavenger Company (SSFSC) and its sister company, Blue Line Transfer in South San Francisco, California. “On week nights, each truck gets a little bit of RNG [renewable natural gas] because that is how it is distributed. Then the tank is topped off with line [natural] gas. On weekends, however, when the trucks are parked for several nights, we cut the line gas and are able to fill all 27 trucks with RNG.”

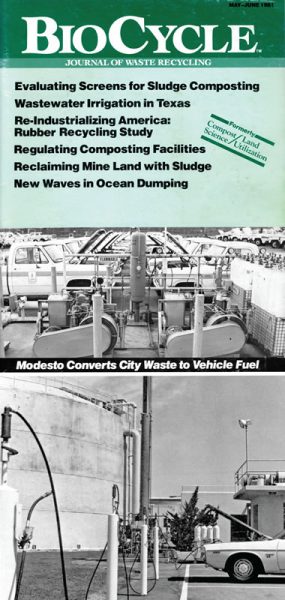

BioCycle May/June 1981 cover and photo cover article.

The RNG is produced by SSFSC/Blue Line Transfer’s anaerobic digestion facility — featured on this month’s cover — that processes residential and commercial food scraps and green waste collected by SSFSC in the South San Francisco area. It has a carbon negative value of -23.95, which makes it a valuable commodity in California, a state with aggressive greenhouse gas (GHG) emissions reduction goals and a Low Carbon Fuel Standard with credits trading at $85 to $100/ton of MTCO2e emissions reduction.

During our interview with Button, he explained how the 27 trucks equipped with CNG engines are lined up at the fueling area. We thought that image would make a great cover photo — and then recalled a similar photo used on the cover of BioCycle many years ago. That prompted a search, which brought us to the cover of the May/June 1981 issue. The article was titled “Municipal Waste To Vehicle Fuel” and was written by R.A. Henrich of Central Plants, Inc. (CPI). The caption of the opening photo read: “Modesto plant superintendent John Amstutz refuels his vehicle in 3 to 5 minutes at first digester gas processing system in United States.”

The biogas (aka RNG) was produced by the Modesto (CA) wastewater treatment plant (WWTP) anaerobic digester and conditioned with a then new process known as Binax, developed by CPI, producing a gas that was 98 percent methane, “suitable for injection into a natural gas pipeline or use as a vehicle fuel.” The Binax system was installed at the Modesto WWTP in 1978. A vehicle conversion system developed by CPI’s affiliate, Dual Fuel System, Inc. (DFS), enabled gas powered vehicles to operate interchangeably on compressed methane and gasoline.

And ready for this? CPI and DFS, at the time, were subsidiaries of Pacific Lighting Corp., whose major holding was Southern California Gas Co.! The stated motivation in 1981 was to be “more independent of imported gasoline,” said Ross Campbell, Modesto’s Director of Public Works.

In 2016 — 35 years after BioCycle’s 1981 cover story — one new element in the mix is use of RNG to significantly reduce GHG emissions. What hasn’t changed is that utilizing digester gas as fleet fuel is still a great idea.