Ron Alexander

Top photo courtesy of McCain Foods (Canada)

The U.S. composting and organics recycling industry has been greatly expanded over the past 20 years, and a pragmatic expansion will likely continue for another 10 to 20 years as infrastructure for food waste management is developed. As the quantity of compost produced and brought to market increases, a great deal of sales and marketing will be required to utilize this increasing volume of compost, while maintaining or increasing product value in the marketplace. While statewide and national compost market development activities have been helpful until now, additional efforts will be required. Many compost manufacturers have successfully expanded markets through their sales activity, however many others will have to step up their game, getting much more active in sales and marketing. In turn, this will require hiring staff to fulfill this role, and creating budgets for associated activities.

These actions lay the foundation for a much more financially stable business model, with money generated by both tipping fees and compost sales. Examples from around the world have shown that as proper market competition grows — defined as selling quality products, at a fair market value, using technically skilled sales staff — market acceptance expands rapidly. The speed at which the market (and end user acceptance) expands will remain limited unless individual composters engage in “true” ongoing sales and marketing activities. Without it, compost in certain regions of the U.S. will remain a primarily undifferentiated, unbranded commodity sold on price alone. This will not lead to a healthy long-term U.S. composting industry.

Protecting The Goose

One great positive in the current U.S. marketplace is that a variety of large-scale compost use projects (e.g., highway erosion and soil manufacturing projects) and large agricultural end users are being developed. These types of projects and end users absorb large volumes of product, but don’t always generate great income for composters. (Conversely, compost sold for landscaping projects (public and private) and topsoil manufacturing, and at retail outlets, can be priced moderately to substantially higher.) Further, since this current marketplace model of high volumes at a lower price point will likely continue into the foreseeable future in certain areas of the country, it is timely to offer a gentle reminder (and warning) to compost manufacturers in the U.S. industry: Be careful not to kill the goose that laid the golden egg. We must stay engaged with large end users and with the entities that specify use of compost for those projects.

A subset of that moral is: Don’t let one bad apple spoil the whole bunch. In the past, in certain regions of the country where compost was being specified for large projects (e.g., 5,000, 10,000, 20,000 cubic yards or even greater), companies willing to cheat to obtain the project or fulfill its requirements would surface. Methods included not filling up the trucks or delivering the proper volumes of product to the project site (something that a load measurement technology offered by LoadScan can address to some degree); delivering substandard product, instead of quality that was expected; and the ever popular bait and switch, where a particular product is specified for the project, the composter provides a sample and test results which meet the specification, then delivers a different, noncompliant product.

A derivation of the bait and switch occurred in the earlier days of the US Composting Council’s (USCC) Seal of Testing Assurance (STA) Program. A STA certified product was specified on a project and then partially delivered. The composter then obtained noncompliant compost to fill the rest of the order. This, of course, was not allowable, and the USCC learned about this violation through an anonymous whistle blower.

The composting industry now has large end users and specifiers in the U.S. (such as State Highways Agencies) specifying STA certified composts that also have to meet the clients’ internal horticultural specification (e.g., pH, electrical conductivity (EC), screen size, etc.). To avoid abuse of the STA certification, the USCC had to install a “morality clause” into its program contract with the compost manufacturers. Any violation of this clause, e.g., a bait and switch, results in being removed from the program for a year. And since certain large volume purchasers will only buy compost certified through the STA program, this is a powerful stick to wield.

Adopting this clause within the certification program has been key to the integrity of the program. Further, because the USCC helped to convince large volume potential end users to purchase only certified compost, the Council had a certain level of responsibility to help them succeed. Bad actors have in the past eroded confidence in compost as a mainstream product. No one in the industry can afford being “guilty by association,” especially if the violation occurs on large and well-publicized projects.

Saving TxDOT For The Composting Industry

In some states, the Departments of Transportation are high volume users of STA-certified compost. Photo courtesy of WSDOT

This exact situation occurred at a time when the State of Texas’ Department of Transportation (TxDOT) was purchasing huge volumes of compost annually. As a consequence, entire TxDOT regions in the state considered ceasing the specification and use of compost. Fortunately, there were some champions for compost use within the TxDOT main office, as well as in the region where the biggest problems had occurred. The regional champion was “sold” on compost because of its performance — vegetation was growing through application of compost where it had never been able to be sustained before. Without these champions, the entire program could have fallen apart right then and there. Several things then occurred to keep the program alive. First, the regional engineer, who supported compost use, put in place an elaborate system to make sure that TxDOT received the product it had specified. Second, the USCC took action.

The new program put in place by this regional office of TxDOT included:

- Prequalifying all potential compost suppliers — which required completing specific paperwork and supplying samples and test analyses for their compost product. This allowed TxDOT to verify that the compost met all agronomic specifications for the particular application (e.g., general landscaping, erosion control, etc.), as well as health and safety requirements (e.g., heavy metal and pathogen limits).

- Proving that the compost manufacturer was a current participant in the USCC’s STA Program, and all of its required testing was up to date.

- If chosen as the supplier, labeling the accepted compost windrows, and having TxDOT monitor the designated windrow with a Global Positioning System.

- Use of specific windrow/product management techniques.

- Allowing TxDOT to randomly audit and test the accepted product.

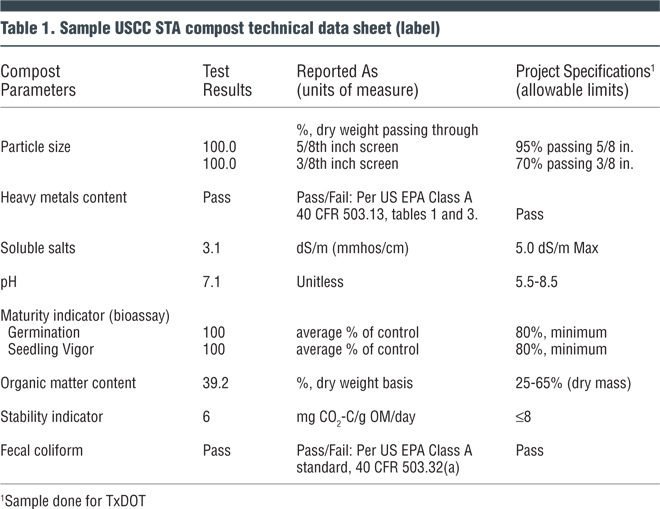

Although these measures seem restrictive, and were expensive to put in place, they did enable the program to continue and weed out some bad actors. To assist TxDOT, the STA Program management developed educational tools for project engineers and inspectors to utilize. One of the tools (Table 1) is a compost technical data sheet (label) generated by the approved testing lab, which lists the state’s current compost specification, as well as the recent test results. This form makes it easier for project inspectors to verify that the product stockpiled at the project site ”meets spec.” In addition, project managers (or other large volume customers) were encouraged to visit the compost manufacturer’s facility to assure that adequate product volumes exist, weed control is taking place on site and that the facility is in general ”working order.” The STA Program staff also developed a checklist to ensure the customer is receiving the compost specified.

Takeaways

Obviously, it is helpful to use the list above to help any compost purchaser know that they are receiving what was ordered and paid for. More importantly, however, it sets up a code of good practice that differentiates compost manufacturers. To avoid “killing the goose that laid the golden egg,” help buyers understand that meeting STA requirements is just the start, and that you can also provide product that meets the horticultural parameters necessary for their particular project. Myself, and several others, have developed voluntary (e.g., for the USCC) and required (e.g., for American Association of State

Highway Transportation Officials, or AASHTO) specifications, with input provided by experts within those specific industries. These specifications have assisted the compost market to grow.

However, we have to continuously work towards the appropriate use of specifications and industry best practices that assure compost buyers are protected. Without creating these assurances, it will be harder to get specifiers to require composts usage on large projects. Quality compost is poised to be a major player in programs to build healthy soils, sequester soil carbon, manage storm water, etc. Its track record has been proven in critical and related end markets. Protecting that hard-earned product reliability and the performance of compost manufacturers participating in certification programs is paramount. In turn, this creates strong secondary income streams for compost manufacturers, which makes the overall industry stronger. To do this, we need to educate the compost end use marketplace, and treat them fairly. The “real” money in compost sales comes from the repeat orders.

Ron Alexander is a horticulturist with over 30 years of experience working with compost and other organic recycled products. He is the President of R. Alexander Associates, Inc., a consulting firm specializing in organic recycled product and market development, and is a co-chair of the US Composting Council’s Market Development Committee. Mr. Alexander has authored compost specifications in several countries around the world, as well as the Practical Guide to Compost Marketing and Sales. www.alexassoc.net.