Alternative sources of nutrients such as organic-based vermicomposts could supplement a large portion of conventional fossil fuel-based hydroponic solutions.

N.Q. Arancon, John Dean Owens and C. Converse

BioCycle September 2018

Tomato experimental treatments from 100% nutrient solution (1) to 50% nutrient solution and water (2) to increasing amounts of vermicompost tea — from least (about 15%) to most (>50%) (3,4,5).Hydroponics is a water-based horticultural practice that grows a wide variety of crops using closed systems with a provision of fertilizer. The two primary hydroponic growing methods are circulating and static systems, the latter being the most common. The static hydroponic system can be constructed easily with wooden boxes lined with plastic to contain nutrient solutions. A favorable feature of this system is that the nutrient solutions are not circulated, hence, it does not need any electricity and the cost associated with the operation is substantially low.

The wooden growing tanks are usually covered with Styrofoam that has holes to suspend individual net pots. The environment and the crops being grown can determine if the hydroponics system will be enclosed, or out in the open. However, crops grown hydroponically still depend on nutrient solutions that contain costly, fossil fuel-based inorganic nutrients. Using alternative sources of nutrients such as organic-based vermicomposts could supplement a large portion of conventional fossil fuel-based hydroponic solutions.

Vermicomposts are produced by interaction of earthworms and associated microorganisms. Their quality varies depending on many factors, including earthworm species, raw material used, and age of the compost. Vermicomposts are generally of finer structure, contain more nutrients, and have higher microbial activity than other types of composts. They have been demonstrated to increase crop growth and yields in the greenhouse and field due to high microbial diversity and population contents that are involved in mineralization of nutrients. These are responsible for suppression of pathogenic microorganisms and production of plant growth regulators such as hormones and humic acids.

Aqueous extracts from vermicomposts, commonly referred to as ”teas,” are innovative ways to utilize vermicompost. Relatively smaller quantities of vermicomposts are required to cover a larger area of production while extracting all the excellent biochemical properties of solid vermicomposts. Initial experiments in the hydroponic greenhouse have showed that when pak choi grown in 50:50 (nutrient solution:vermicompost tea), yields were comparable with those plants that were grown in 100 percent nutrient solution. The experiment reported here used lettuce and tomatoes in place of pak choi. Goals of this research were to demonstrate the benefits of using vermicompost as a substitute for hydroponic nutrient solution and evaluate its effects on the growth and yield of lettuce and tomatoes.

Materials And Methods

The project was conducted at a hydroponics greenhouse at the University of Hawaii at Hilo farm, Panaewa, Hawaii. The nutrient solution (electrical conductivity (EC) of 1.5 to 2.0 mS) was prepared from two concentrated stock solutions, as described by Kratky (2010), that were added in equal volumes to water in the storage tank. The stock solutions were prepared in two 95-liter (L) tanks, marked containers A and B. One stock solution consisted of 120 g/L of a commercial (Hydro-Gardens, Colorado) hydroponic fertilizer (8% N, 6.6% P, 29.9% K, 0.20% B, 0.05% Cu, 0.4% Fe, 0.2% Mn, 0.01% Mo and 0.05% Zn) plus 72 g/L of magnesium sulfate; the second stock solution consisted of 120 g/L of soluble grade calcium nitrate. For each 3.7 L (1 gallon) of water in the growing tank, 15 ml of each stock solution was added (15 ml/gal). The EC of the nutrient solution was measured using a conductivity meter.

Each treatment was contained in a separate 90-gallon hydroponic tank measuring 8-ft. by 4-ft. by 10-in. Tanks were constructed with lumber, lined with 2 layers of 6-mil black polyethylene plastic sheeting, and filled with 25 cm (9.8 in.) of nutrient solution prior to transplanting. Vermicompost teas are usually prepared by steeping solid vermicomposts in water aerated or nonaerated for 12 to 24 hours; this requires electric-powered brewer systems.

To do away with electricity input in the tea preparations — and since it would take voluminous amounts of tea, hence electrical power, to fill up five 90 gal-tanks for the tomato experiment — solid vermicomposts were incorporated directly into the tanks. Tanks were stirred thoroughly to mix vermicompost in water-nutrient solutions. The percent vermicompost tea in solutions in each treatment reflected the actual amounts of solid vermicomposts by volume. (Authors’ note: Adding solid vermicomposts in the tank was the only practical way of making large batches of tea e.g. 90 gal/tank x 8 treatments. It is possible that using a prepared tea could release more nutrients based on extraction method e.g. the use and type of aeration and pumps, length of extraction.)

Lettuce Experiment

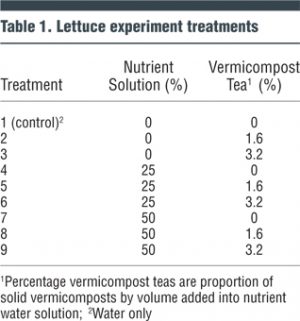

A 3 by 3 factorial experimental design was set up for lettuce: Three levels of nutrient solution (0%, 25% and 50%) and three levels of vermicompost teas (0%, 1.6%, and 3.2%). The solutions were mixed in 3-gal pots and the percentage vermicompost teas were the proportion of solid vermicomposts by volume added into nutrient water solution and stirred thoroughly. Table 1 lists the treatments for the lettuce experiment:

Lettuce seeds were directly sown into 2-inch net pots containing a 1:1 mixture of Sunshine Mix #1 and size 2 Perlite The net pots were suspended by 1-ft. by 1-ft. plywood that was predrilled to accommodate the size of the 3 net pots/3-gal pots. Each treatment had 5 pots with three lettuces per pot totaling 15 replications per treatment. Growth was observed and recorded each week. Harvest data was collected all at once for lettuce and over a period of six weeks for tomatoes.

Tomato Experiment

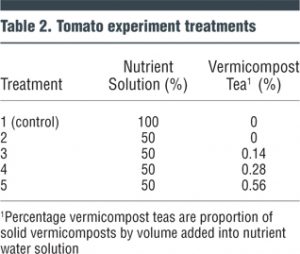

A 90-gal wooden tank lined with 6-mil plastic liner was used for the tomato experiment. As in the lettuce experiment, solid vermicomposts were added into the respective nutrient solutions with percentages of vermicompost tea representing amount of vermicompost added to each treatment by volume (Table 2). Plywood (8-ft. by 4 ft. by 0.75 ft.) was used to suspend the net pots for the tomato seedlings. Each board had 6 predrilled holes representing 6 replications per treatment. Tomato seedlings were raised in the greenhouse for six weeks in a soilless Sunshine Mix (a mixture of vermiculite, composted bark, sphagnum and perlite; no vermicomposts were added). Seedlings were transplanted into suspended net pots with 1:1 perlite and Sunshine mix #1 growing media. Tomato harvest data was recorded as both number of fruits and weight measurements of marketable and nonmarketable fruits.

Results

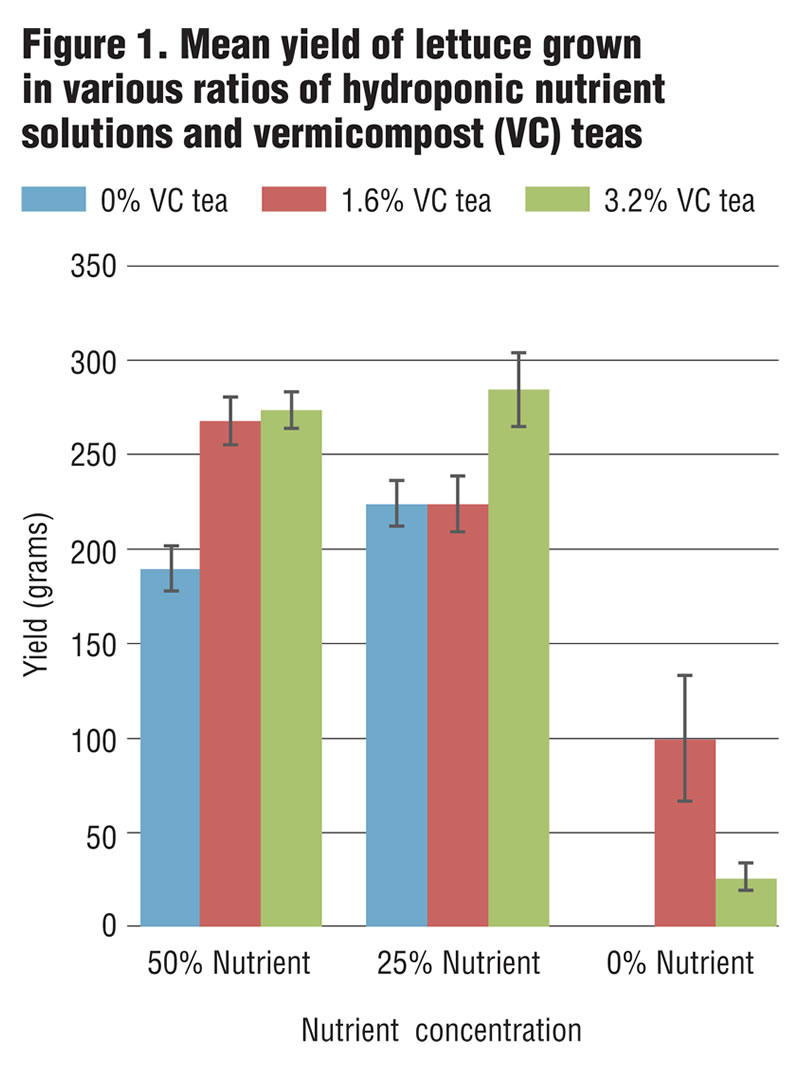

Figure 1. Mean yield of lettuce grown in various ratios of hydroponic nutrient solutions and vermicompost (VC) teas

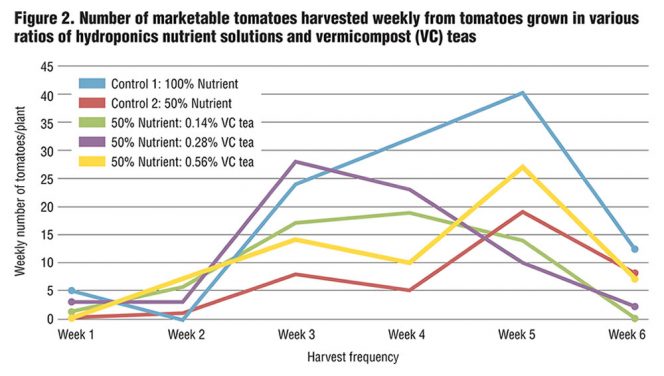

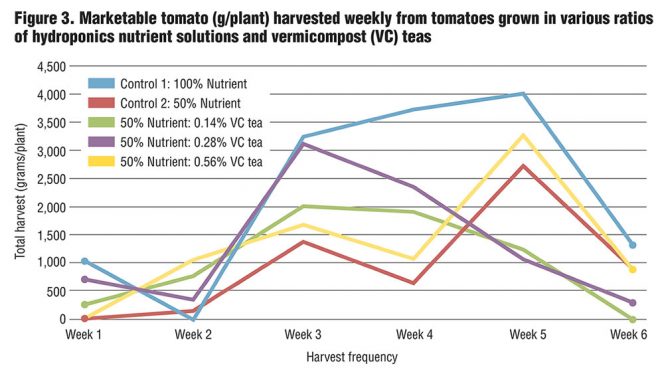

Figures 2 and 3 show tomato harvest data from each treatment over a 6-week period. The heaviest production overall can be seen from tomatoes grown in 100 percent nutrient solution (Control 1). However, 50 percent nutrient:0.28 percent vermicompost produced similar fruit yield until week 4, when a decline in harvest numbers continued until week 6. All other treatments produced significantly lower throughout the study.

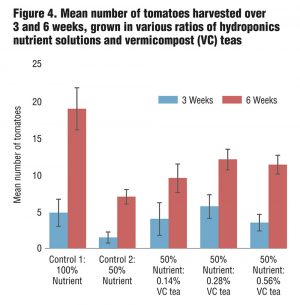

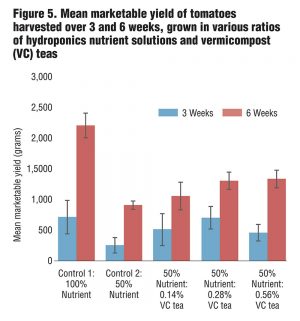

Figure 4 and 5 show the average production of each treatment over 3 weeks and the entire harvest season. Yields from plants grown in 100 percent nutrient solution were significantly greater than all other treatments. However, there is no statistical difference between all other treatments.

Discussion

Figure 2. Number of marketable tomatoes harvested weekly from tomatoes grown in various ratios of hydroponics nutrient solutions and vermicompost (VC) teas

Figure 3. Marketable tomato (g/plant) harvested weekly from tomatoes grown in various ratios of hydroponics nutrient solutions and vermicompost (VC) teas

If there were room for improvement, a statistically significant difference would be evidenced in the application of twice as much vermicompost (as was seen with 25% nutrient category). Given this evidence of vermicompost’s effective use as a replacement fertilizer, high levels of vermicompost (3.2%) are still not enough to compensate for a complete lack of inorganic nutrient.

Data collected from the tomato section of this study show a strong possibility for vermicompost’s use as a replacement fertilizer in hydroponic tomato culture. While Figures 2 and 3 display the inability of vermicompost to act as a replacement fertilizer over an entire season of harvest, the need to replenish water and nutrient levels over the relatively long growth cycle of tomatoes was not taken into account. Periodically, water and inorganic nutrient were replenished on an as needed basis for each treatment at their given percentage (thus skewing results toward higher yields with 100% nutrient solution over the 6-week cycle). It is possible that at the beginning of the fourth week the nutrient solutions with vermicompost became anaerobic as a result of depletion of dissolved oxygen as microbial populations increased.

However, due to the possible build up of sediment in the tanks, vermicompost rates were not replenished as the study progressed. The high initial numbers of the 50 percent nutrient-0.28 percent vermicompost treatment point to vermicompost’s potential as a replacement fertilizer if vermicompost rates are able to be maintained throughout the production cycle. Without the addition of fresh vermicompost when tanks are refilled, it cannot be recommended as a replacement nutrient for tomatoes at this time.

Figure 4. Mean number of tomatoes harvested over 3 and 6 weeks, grown in various ratios of hydroponics nutrient solutions and vermicompost (VC) teas

This trend is continued from week four through week six in flower production. It is likely that after several weeks the hormones and nutrients present in the vermicompost are depleted to an extent that the plant can’t derive benefit from it. If vermicompost levels are not replenished, the plant will eventually enter decline starting around week eight or nine.

It is important to note that vermicompost applied minimally (i.e., 0.14% or 0.28% or in 50% nutrient solution in tomato experiment), or even as low as 3.2 percent in 25 percent nutrient solution in the lettuce experiment, yielded equally well with those in 50 percent or 100 percent nutrient solutions in lettuce and tomatoes, respectively. The advantages of the utilization of organic amendments, especially vermicomposts, do not come from its nutrient content. Recent experiments involving vermicompost teas used in germination studies (Arancon et al., 2012) elucidated important composition of vermicomposts — such as growth hormones and metabolites — not usually found in nutrient solutions. Presence of a small quantity (198 ng L-1) of GA4 in 10 percent chicken manure-based vermicompost tea increased germination rates of tomato seeds (Arancon, 2012). This finding would support the increases in yields of lettuce and tomatoes despite the small quantities of vermicompost applied into the hydroponics solution.

Figure 5. Mean marketable yield of tomatoes harvested over 3 and 6 weeks, grown in various ratios of hydroponics nutrient solutions and vermicompost (VC) teas

The implications of this study are that it is possible to replace a large percentage of relatively expensive inorganic nutrients, by approximately 50 percent, with vermicompost — an amendment that can be produced by most individuals at low cost. This change in fertilizing procedure could save hydroponic farmers money and protect the environment from the potentially damaging effects of fossil fuel-produced fertilizers.

Dr. Norman Q. Arancon is an Associate Professor of Horticulture in the College of Agriculture Forestry and Natural Resource Management, University of Hawaii at Hilo. He currently teaches courses such as Sustainable Agriculture, Tropical Fruit and Nut Production and Vermiculture. John Dean Owens holds a BS degree in agriculture from the University of Hawaii, Hilo. Chad Converse is an alumni of the University of Hawai’i at Hilo with a BA in Marine Science and Communications. He worked as a research scientist at the University of Hawai’i at Hilo.