BioCycle January 2014

San José, California: Mixed Organics AD, Composting Facility Opens For Business

Zero Waste Energy Development Company (ZWEDC) held the grand opening of Phase One of its large-scale commercial dry fermentation anaerobic digestion (AD) and composting facility in November. The facility, designed to achieve LEED Gold certification, is being built in three phases, each with capacity to process up to 250 tons/day (up to 90,000 tons/year). The fully enclosed ZWEDC Phase One plant houses 16 anaerobic digesters plus four in-vessel composting tunnels that utilize the Kompoferm technologies. It receives the City of San José’s commercial organic waste delivered through a 15-year exclusive organics processing agreement with the City. In July 2012, San José adopted a dry/wet collection system for businesses. Republic Industries has the contract with the City to collect the commercial waste; it installed new processing lines at its Materials Recovery Facility on Newby Island, including a separate sort line for organics-rich loads (see “Creating Infrastructure For Commercial Waste Diversion,” August 2011). The organic material delivered to the AD plant includes pre and postconsumer source separated food waste, residuals from processing wet and dry materials and yard trimmings. The AD and composting systems are supplied by Zero Waste Energy, LLC, which holds the exclusive license for the Kompoferm technologies in North and South America and Asia. ZWEDC was formed in 2011 by GreenWaste Recovery, Inc. and Zanker Road Resource Management (Zanker) to improve local organics recovery.

Two 800 kW 2G Cenergy combined heat and power supply units have been installed. After meeting on-site power needs, surplus energy will be provided to Zanker’s C&D processing facility near the AD plant. During off-peak hours, surplus power will be sent back to the grid. Future phases are anticipated to produce renewable compressed natural gas to be used as vehicle fuel. About 30,000 tons/year of finished compost will be produced. (ZWEDC has a long history of composting organics from the City of San José, at a green waste and mixed organics facility in Gilroy, California.) The ZWEDC facility site was an unclosed, City-owned landfill. ZWEDC invested $11.8 million to close the landfill and develop infrastructure on the site as prepayment for its 30-year lease.

Albany, New York: Green Bank Receives Needed Funding

Last January, New York State Gov. Andrew Cuomo launched the Green Bank to provide financing to the state’s renewable energy sector. Recently, the bank was awarded $210 million, enabling it to open in early 2014. This initial funding comes from $165 million in energy bills approved by the New York Public Service Commission (PSC) and $45 million from the Regional Greenhouse Gas Initiative (RGGI). Cuomo said future funding would come from these sources with hopes of reaching $1 billion. “With this funding we will attract greater investment in New York, accelerate clean energy deployment, and modernize our grid,” he noted. “Working hand-in-hand with the private sector, the New York Green Bank will also promote job growth, improve air quality, and provide New Yorkers with greater choice and value for their money.”

The Green Bank will partner with private sector lenders by providing financial products such as credit enhancement, loan loss reserves and loan bundling to support securitization and build secondary markets. These products will support economically viable clean energy projects that cannot currently access financing due to market barriers, such as federal policy uncertainty, insufficient performance data, and the lack of publicly-traded capital markets for clean energy. These barriers limit private sector capital flows into otherwise attractive renewable energy and energy efficiency projects, creating gaps in the clean energy finance market.

“Governor Cuomo’s launch of a Green Bank places New York among the first few states in the country to pioneer a market-based approach to tackling climate change,” Environmental Defense Fund President Fred Krupp said. “The move will encourage much-needed private sector investment in renewable energy and energy efficiency, create jobs, and ensure a more resilient and sustainable energy infrastructure.”

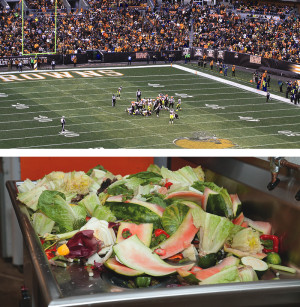

Cleveland, Ohio: Stadium Food Waste To Campus Digester

FirstEnergy Stadium, home of the Cleveland Browns football team, is also home to a new grinding system that is processing food waste generated on game days and at other events. The slurried food waste is transported to an anaerobic digester operated by quasar energy group at Ohio State University’s Ohio Agricultural Research and Development Center (OARDC) in Wooster. The digester, where cow manure is added periodically to lower acidity, produces biogas for energy and fuel uses. The Grind2Energy system, manufactured by InSinkErator, was installed in FirstEnergy Stadium prior to the season and has been used during all games. It has a 2,500-gallon tank for storing slurry between collections. A similar system is installed nearby at Forest City Enterprises’ Tower City complex (see “Why Is A Real Estate Giant Bullish on AD?”, September 2013). The stadium is expected to divert 35 tons of food waste per season to anaerobic digestion — and recover enough nutrients for three football fields of new crops, according to quasar.

Batavia, New York: Ag Park Digester Wins $2 Million Grant

Genesee Biogas, a CH4 Biogas project, received a $2 million grant from the New York State Energy Authority to design, build and operate a biogas plant to support the Genesee Valley Agri-Business Park (Ag Park) in Batavia, Genesee County. The plant will convert organic waste streams produced by dairy farms and other agricultural and food processers in and around the Ag Park and the region into renewable energy for use by park tenants and regional industry. The Ag Park is home to two Greek yogurt plants. Alpina, one of the two yogurt plants, is currently hauling between 8,000 and 16,000 gallons/day of whey to a farm-based digester in Covington, New York, operated by CH4 Biogas. Genesee Biogas will locate the digester near the yogurt plants. The Ag Park is owned by Genesee County Economic Development Center (GCEDC), which is the county’s industrial development agency. GCEDC officials wanted to attract a digester to the Ag Park to provide electricity to its tenants and provide an economical way to manage food processing waste from the yogurt plants.