Good site design and not erring from composting process fundamentals are keys to odor control at composting facilities. Part II

Craig Coker

BioCycle May 2012, Vol. 53, No. 5, p. 35

This article series examines the intricacies of odor management: how and where odors are generated, measured and perceived; how they are managed through good process control; how they are controlled with technology; and how to manage the public outreach related to organics recycling odors.

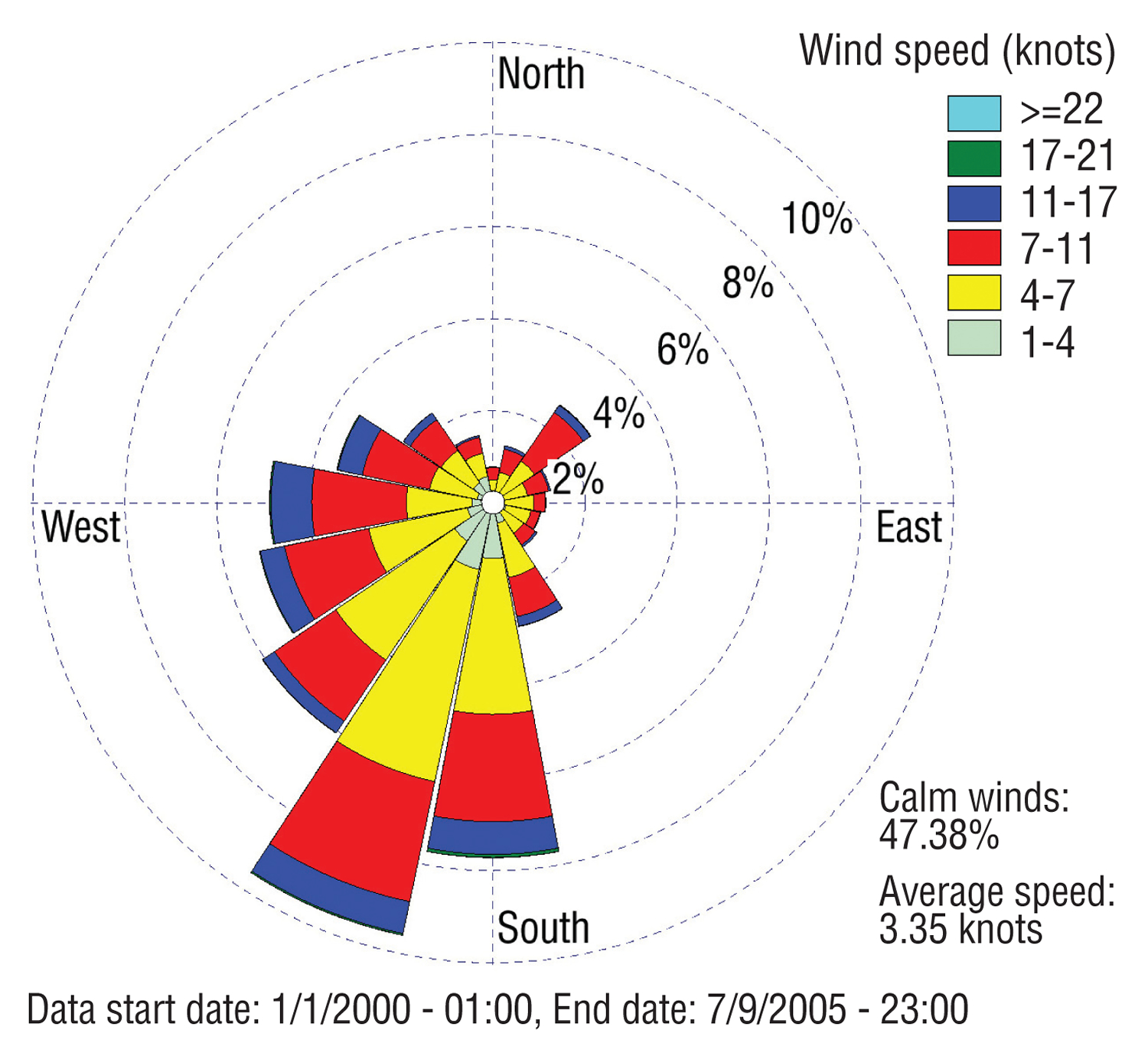

Once the prevailing wind directions and speeds are known, the layout and operation of the site can consider potential impact of odors on receptors. A sensitive receptor can be defined as any place where members of the public may gather, such as a house, school, park, church or shopping area. For initial siting and site layout, locate waste management aspects of the facility (e.g., waste receiving, mixing and active composting) at least 1,000 feet (and preferably 1,500 feet) from any sensitive receptors in the predominantly downwind direction (south, south-southwest, and southwest in Figure 1). Plan on a thickly vegetated buffer of fully developed vegetation in that direction so that vegetative surfaces can intercept and filter particulate matter that may contain odorous compounds.

Orient the site so that odor-producing activities are sheltered by trees, hills, buildings, walls and other features that break up the wind pattern to create turbulence. Turbulent wind patterns disperse odors faster than laminar, or smooth, wind patterns. Turbulent dispersal is important, as the odor detection and recognition thresholds of some compounds is extremely low. Other site planning and development steps that can reduce potential for odor problems include: leaving room for equipment to get to piles or windrows for implementing odor-related best management practices (BMPs) as needed (such as installing a compost cap or watering windrows prior to turning), and designing the site for rapid and effective runoff and drainage management to prevent odorous puddles from forming.

In Figure 1, note that the predominant wind speeds are less than 11 miles per hour, meaning there are significant blocks of time with very low wind speeds (i.e., less than 4 miles/hour) so there is little dispersal and dilution of odorants. During low wind speed events, activities that might generate odors should be avoided as much as possible without unduly constraining operations. These activity restrictions might include delaying waste mixing, pile building, windrow turning, etc. until the wind picks up. Operational decisions and practices that can minimize the potential for odor episodes will be covered in a future article.

Optimum Conditioning

Composting is never odor-free. Even under optimum conditions for aerobic decomposition of organic matter, odors are going to form. However, failure to develop those optimum conditions is guaranteed to make odors worse, particularly those odorants that people find annoying or unpleasant. The more odors that are formed due to poor composting conditions, the more quantities of that odorant escape into the atmosphere, and it becomes much harder to disperse those quantities below the recognition thresholds. The detection threshold of an odor is the minimum concentration that the human nose can perceive something in the air but not identify it; the recognition threshold is the minimum concentration that a human receptor can identify the odorant. The recognition threshold of an odor is much higher than the detection threshold; for example, ammonia has a detection threshold of 0.037 ppm, but a recognition threshold of 47 ppm.

“It all starts with the mix,” says Tim O’Neill, President of Engineered Compost Systems. “You have to start as close as you can to this mix or odor control technology won’t help. I’ve worked with quite a few biosolids composting facilities that started out with a C:N ratio that was too low; they had not accounted for the fact that some of the carbon in an amendment is not available to the microbes.” O’Neill recommends that facilities have bench-scale reactors on-site (see box) to test different recipes before trying them in full-scale applications to learn more about the odors with each recipe.

Controlling Microbial Activity

No one practice influences odor generation potential more than another; rather it is a combination of smaller steps to be managed, including particle size, moisture content and air flow.

Particle Size

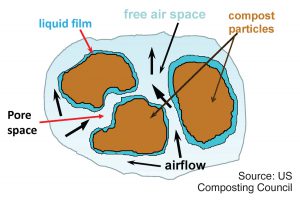

As illustrated in Figure 2, the effectiveness of microbial metabolism on the compost particle is defined, in part, by the surface area-to-volume (SAV) relationship of the particle. The SAV explains why finely-ground salt dissolves in water faster than coarsely-ground salt. If SAV is too high, the interior of that particle will take a very long time to compost. If it is too low, then the particles in the pile can’t support themselves and they collapse the free air space between them, reducing the ability of the pile to stay aerobic. Particle sizes should be in the 2- to 3-inch range.

One way to manage this in the field is with bulk density (the ratio of mass to volume of a specific material). A high bulk density means there are smaller particle sizes and narrower pore spaces; it also means there is more organic material to decompose in a given volume of mixed feedstocks. Initial compost mixes should have a mixed bulk density below 1,100 pounds per cubic yard (lbs/cy).

Moisture Content

The correct moisture content advances the rate of decomposition. There are three types of water in a compost pile: free (gravitational) water, which drains out by gravity (a soaked pile after a rainstorm); capillary water, which is cohesively- or adhesively-bound to the particle and forms the biofilm in which the microbes live; and intracellular water, which is contained inside the cells of plants and animal tissue. The capillary water is most important to good composting, but variations in moisture from release of intracellular water need to be considered.

If the biofilm around the particles dries out, microbial activity will go dormant and composting will stop. As piles dry out, the concentration of potential odorants in the biofilm increases. This can cause a chemical equilibrium shift between soluble and volatile forms for odorants such as ammonia or the terpenes found in green wastes. As mentioned in Part 1, when a chemical volatilizes, it becomes a gas and migrates out of a compost pile by either passive or forced aeration. Conversely, if moisture is allowed to climb above 60 percent or so, the free air space channels between the particles clog with water. This thicker biofilm reduces the amount of oxygen available to the microorganisms on the surface of the particle as the rate of oxygen transfer in water is much slower than the rate of transfer in air. Material with an optimum moisture content of around 50 to 55 percent has the consistency of a wrung-out sponge that is wet but not freely dripping water.

One of the challenges in composting food scraps containing large amounts of vegetable and fruit material is that the plant cell walls break open readily under the heat of initial decomposition, flooding the pile with water. Without adequate structural porosity to allow that flush to drain out, the pore spaces in the pile will fill with water and risk formation of anaerobic conditions.

Air Flow

Transfer of oxygen across the biofilm requires a steady flow of air through the pile. Whether by natural or passive means, or forced through a pile by a blower, aeration serves several critical functions in process management, including replenishment of oxygen, removal of carbon dioxide (and volatile odorants), and removal of heat. Compost piles and windrows have both macro aeration and micro aeration characteristics. Macro aeration refers to the overall uniformity of the structural porosity of a pile. A compost pile comprised of wet dairy manure mixed with sawdust has low macro aeration characteristics. A compost pile of chipped tree waste has good macro aeration characteristics. Good macro aeration characteristics are necessary where passive aeration is the primary means of oxygen transfer, like in windrows.

Micro aeration characteristics refer to how well air moves inside the pile. Fine particles, such as those produced by processing woody wastes with a hammermill, can impede aeration rates and create air-starved sections in a pile. Piles with a lot of paper in them also can create poor micro aeration characteristics. “The agglomeration of the paper particles can clog air channels in the pile,” notes O’Neill. “Poor micro aeration in food scraps compost piles can depress pH, which leads to formation of volatile fatty acids that make that sickly sweet smell.”

Release Of Odorants

Part 1 of this series noted that odorants are produced at various stages in the decomposition process and that there is a sequence of events in which the odorants generated by initial stage decomposition are degraded by microorganisms in the pile during composting. Forced aeration systems, particularly those with deliberately-elevated aeration rates, can strip odorants out of a pile before they have had time to decompose. This can be a problem if the fans strip odorants out of air-starved portions of the pile, putting pressure on the external odor control system (e.g., biofilter) to handle the load. This should be factored into the system design, e.g., gas (odorous air) retention time should be more like 60 to 70 seconds instead of the minimum 45-second retention time. This requires a deeper biofilter (versus more area).

In windrow systems that rely on the “chimney effect” of passive aeration, the high temperatures of early composting enhance the air flow through the windrow, potentially carrying off odorous compounds. That can be minimized by covering windrows with a 4-inch layer of unscreened compost to act as an in-situ biofilter. However, it is easy to overload a compost cap and suffocate the windrow.

As feedstocks decompose, they provide nutrients to the microbes, which use them to sustain their metabolism. Excess nutrients are not processed and can accumulate. As the biological and chemical changes in a pile shift the equilibrium between soluble and volatile forms of a chemical, these nutrients can be volatilized and become an odorant. The most notable example of this is ammonia emissions from a pile with a C:N ratio below 20:1. Conversely, composting piles with high C:N ratios, like leaves and green waste, can emit odors from volatile carbon-based chemicals like hexanal (C6H12O), pentanal (C5H10O), acetone and methanol. Hexanal is the odor of fresh cut grass and pentanal has an acrid, pungent odor.

Not all carbon is available for microbial metabolism. A chemical found in all plants, lignin, is very difficult for bacteria to decompose. Lignin is a phenolic polymer and fills the spaces in the cell wall between cellulose, hemicellulose and pectin components. Lignin is particularly abundant in paper and wood, where it can comprise 18 to 22 percent of hardwoods (on a dry weight basis) and 26 to 33 percent of softwoods. So, a compost pile with wood chips as a bulking agent will have a lower bioavailable C:N ratio than would be indicated by a laboratory analysis of Total Carbon and Total Nitrogen. This has the potential for odor episodes characteristic of a low C:N pile, such as the heavy, sour smell of a low C:N food scraps compost pile.

Das (2000) presents a procedure for adjusting C:N ratios based on lignin content; one example calculation is shown in Table 1. Adjusting compost recipes for nonavailable carbon can significantly increase the volume ratio between carbonaceous and nitrogenous feedstocks from the traditional 2-3:1 to as much as 6-8:1.

Following best management practices in site layout and design and in compost pile recipe development and construction will not eliminate odors, but will greatly reduce the potential for odor episodes that will cause problems. Part III of this series will examine operational practices to minimize odor episodes.

Craig Coker is a Contributing Editor to BioCycle and a Principal in the firm Coker Composting & Consulting (www.cokercompost.com),near Roanoke VA. He can be reached at cscoker@verizon.net.

References

Das, K.C., 2000 Odor Related Issues in Commercial Composting, Workshop presented at the Y2K Composting in the Southeast Conference & Expo, October, 2000, Charlottesville, VA.

Top 5 Signs Of Impending Odor Problems (and how to troubleshoot them)

1. Excessive Moisture: If windrows, mix in dry material (compost, sawdust, etc.); don”t just turn windrow. If aerated static pile (ASP), turn up fan airflow and keep fans running.

2. Low C:N Ratio: Mix in high available carbon material, ideally sugars, starches, etc.

3. Low pH: Mix in wood ash; High pH: Mix in acidic material (food scraps).

4. “Heavy Air” (low ground fog): Don’t turn windrows; if ASP, check biofilter for short-circuiting.

5. Post-rainfall puddles: Soak up with absorbent material (compost, sawdust, etc.).

Bench Scale Reactors (and how to build your own)

Having a bench-scale reactor on site to test different recipes before trying them at full-scale helps predict odor generation. Here are some quick tips on building one:

Windrow System: Use a backyard wire-cage composter

Forced Air Reactor: Fit a large aquarium air pump to a plastic 55-gallon drum

Measuring Free Air Space (and how to make sure you have enough)

The 5-gallon bucket test is a simple way to measure free air space in a compost pile — before it’s built. The materials needed include a 5-gallon pail, a 1-gallon plastic milk jug, and the typical mix of materials added to the compost pile (manure, grass clippings, straw, wood chips, shredded bark, etc.)

1. Check the volume of the 5-gallon pail by filling the 1-gallon jug and emptying it into the 5-gallon pail 5 times. Mark the 5-gallon “full line” on the pail.

2. Fill the pail one-third full with a typical mix of compost materials and drop the pail 10 times from a height of 6 inches onto a cement floor or sidewalk (being careful to keep all the material in the pail).

3. Add more compost material to fill the 5-gallon pail two-thirds full and drop the pail 10 times from a height of 6 inches onto a cement floor or sidewalk.

4. Add material to fill the 5-gallon pail up to the “full .line” and drop the pail 10 times from a height of 6 inches onto a cement floor or sidewalk.

5. Add material to fill the pail to the “full line.”

6. Now add and keep track of the amount water you can add to the 5-gallon pail before it overflows.

• If you can add 2.75 to 3.25 gallons of water to the pail without it spilling over the top, you have adequate free air space. Your initial free air space is correct.

• If you cannot add at least 2.75 gallons of water to the pail without it spilling over the top, you have inadequate free air space. Add more bulking material like straw, coarse wood chips or shredded bark.

• If you can add more than 3.25 gallons of water to the pail without it spilling over the top, you have too much free air space and you need to reduce the particle size. This can be done by grinding or shredding the materials or by adding finer materials to the mix.

7. Make the needed corrections and retest until the test shows the correct initial free air space.

Source: “Composting and Mulching: A Guide to Managing Organic Yard Wastes”, University of Minnesota Cooperative Extension, BU-03296, 2000