Renewable natural gas — which is cost-competitive with diesel fuel and carbon neutral — is the next game-changer in vehicle fueling.

Stephanie Thorson

BioCycle August 2015

Canada and the U.S. have made good progress in greening electricity grids, but when it comes to greening natural gas grids, progress has been too slow. However climate change, opposition to fossil fuel pipelines, and the need for more local energy sources to reduce dependence on oil imports all point to the need for more renewable natural gas (RNG). In turn, RNG is gaining traction among local governments eager to transition to renewable energy and lower their carbon footprint. And RNG — which is cost-competitive with diesel fuel and carbon neutral — is the next game-changer in vehicle fueling.

As municipal fleets and transit vehicles move to compressed natural gas (CNG), it is a seamless exercise to blend in RNG, since the fuel is entirely interchangeable. Municipalities can generate their own RNG from green bin collection, wastewater treatment plants and landfills. The Canadian Biogas Association (CBA) recently published “Closing the Loop: Primer for Municipalities, Food Processors and Fleets on Fueling Vehicles Using Renewable Natural Gas.” Organizations can Close the Loop in three ways: Stop sending organic materials to landfill, and instead harvest vehicle fuel; Fuel your fleet from local organic material; and Use locally-produced RNG and keep energy dollars in your community instead of purchasing fossil-fuel based diesel and gasoline produced outside your community.

The Primer helps identify if compressed natural gas (CNG) and RNG are right for a community, outlines how RNG fits with municipal planning and policy development, and highlights case studies and lessons learned. It is part of a larger collaborative Closing the Loop initiative, which includes workshops, tours, and networking to promote adoption of RNG as a vehicle fuel.

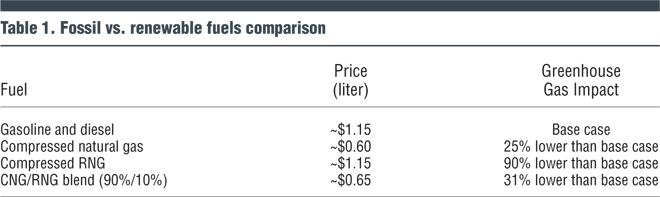

Table 1 uses five year price averages to compare the per liter price between RNG and other vehicle fuels. It also estimates the greenhouse gas (GHG) impacts of each. Displacement of a carbon-positive fuel, such as natural gas, with RNG fuel, results in a net reduction of GHG emissions. The carbon dioxide generated during production and combustion of RNG is used in the regeneration of new biomass, representing a closed-loop cycle for carbon dioxide that is released.

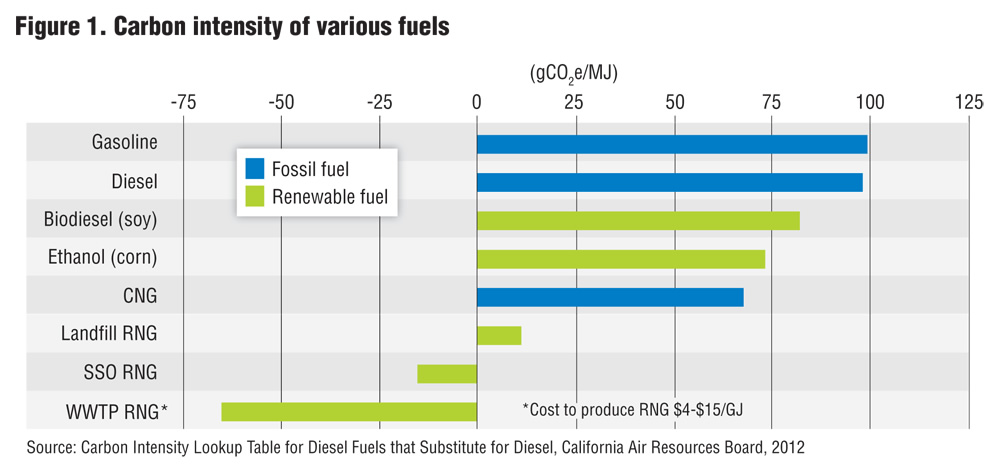

When RNG is used to fuel natural gas fleet vehicles, lifecycle GHG emissions can be reduced by about 90 percent. This is an industry-accepted estimate, and reflects an average of sources of RNG, including agricultural anaerobic digesters. For municipalities, the California data in Figure 1 relates to municipal sources of RNG.

Business Case Considerations

When studying the business case for producing RNG, consider the gas volumes the material can produce, and the cost to do so. Then evaluate what costs this production is replacing to make a decision. The following volumes and outputs gathered from existing and proposed municipal systems can assist with the evaluation:

Generally, one metric ton of source separated organics (SSO) generates 110 cubic meters (m3) of biogas. Depending on the methane content of the biogas, which can range from 50 to 65 percent (depending on the material being processed), one metric ton of SSO can produce about 70 m3 of RNG.

For wastewater treatment, for each 250 m3/day of biosolids treated, an anaerobic digester will produce 1,900 m3/day of biogas.

At Hamilton, Ontario’s wastewater treatment facility, biogas generation rates were based on 0.9 m3 of biogas generated for each 1.0 kg of volatile solids (VS) destroyed in digestion. In 2014, it injected 536,062 m3, or 20,290 gigajoules (GJ) into the Union Gas grid at a rate of 750 N(normal)m3/hr or 500 SCFM. Volumes varied significantly from month to month. Revenue was over $116,000 in 2014. The business case in the future will be strengthened as Hamilton shifts to displacing gasoline and diesel for transit vehicles that will be CNG- and RNG-fueled.

Niagara Region’s wastewater treatment plant is expected to produce 84,000 gasoline gallon equivalent (GGE) per year of RNG and would reduce the municipality’s annual GHG emissions by 1,000 metric tons. The RNG generated would fuel 60 fleet vehicles that would be converted to run on CNG/RNG. The total capital cost of the pilot project is estimated at $1.1 million for the first year and an additional $200,000 annually for the subsequent four years. Payback is anticipated at 9.5 years.

Progressive Waste Solution’s Terrebonne landfill near Montreal is processing approximately 10,000 cubic feet per minute (SCFM) of incoming landfill gas. The energy generated is sufficient to keep the equivalent of 1,500 trucks on the road for 20 years, or the equivalent of a reduction in fossil fuel dependence of 350,000 barrels of oil per year. The new plant will also result in avoidance of greenhouse gas emissions of as much as 1.2 million metric tons of carbon dioxide (CO2) over a 10-year period.

Stephanie Thornson is an Associate with the Canadian Biogas Association. “Closing the Loop: Primer for Municipalities, Food Processors and Fleets on Fueling Vehicles Using Renewable Natural Gas” is available free on the CBA website, thanks to funding from Growing Forward 2, a federal-provincial-territorial initiative, Bio- En Power, Bullfrog Power, and Union Gas. www.biogasassociation.ca