Unmanned Aerial Systems provide composting facilities with more accurate data to manage inventory, contract grinding — and perhaps detect hot spots in piles.

Craig Coker

BioCycle July 2016

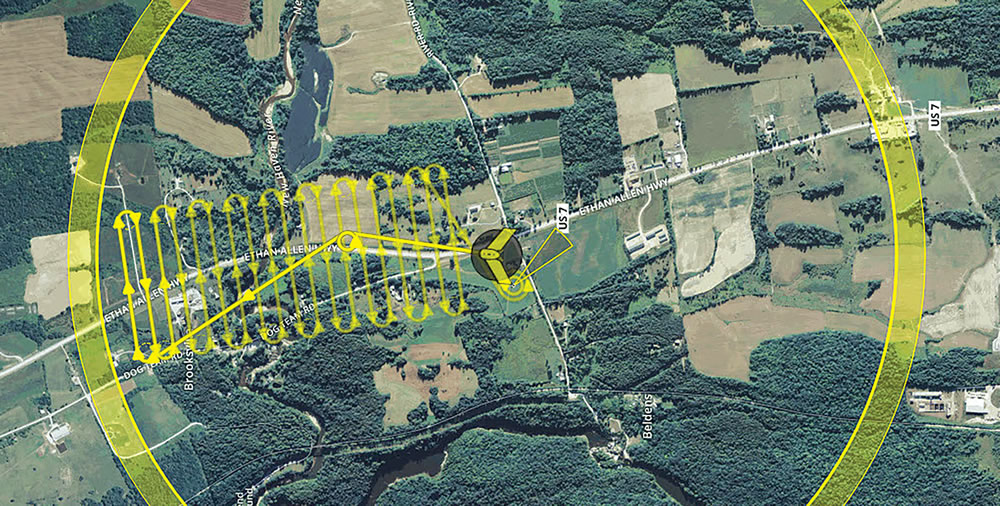

Example of flight pattern for drone. (Image courtesy of Jarlath O’Neil-Dunne, Director of the University of Vermont Spatial Analysis Laboratory. Appeared in Vol.5 No.5 of LIDAR Magazine)

Unmanned Aerial Systems (UAS), which include unmanned flying platforms commonly called drones, along with associated cameras and terrain-mapping software, are a new tool in the composter’s toolbox for keeping accurate records of inventories. Specific measurement of inventories is important for financial reporting, because inventories are valued as assets on a facility’s balance sheet, and changes in inventories can be used to verify sales reports. In addition, for services like contract grinding where the contractor is paid by the finished ground-up volume, accurate inventory monitoring helps verify contractor invoices.

UAS consist of the unmanned aircraft (UA) itself, and all the associated support gear, control station, data links, telemetry, navigation and communication equipment needed to operate the drone. Unmanned aircraft include both rotorcraft and fixed-wing aircraft. Most rotorcraft will fly for 15 to 20 minutes before the batteries need replacement, making them more suitable for flights over 1 to 100 acres. They are easier to operate than fixed-wing UAS and require less training. Fixed-wing UAS will fly for 45 to 90 minutes between rechargings and can handle both heavier payloads and more variable weather conditions. They are considerably more expensive and complicated to master.

The payload that a UAS carries is defined by the project requirements and the capacity of the UA platform. Digital cameras, ranging from sports photography GoPros to high-end digital single-lens reflex cameras, are the most common payload, although specialized spectral sensors are used for mapping particular environmental features like wetlands. Full-motion video cameras are also available payloads, which can produce geocoded videos that can be viewed inside Geographic Information Systems (GIS) models.

Operator Regulations

One challenge in using UAS is that regulations governing their use are in flux and can vary depending on location. UAS operators need to comply with federal, state and potentially local regulations. On the federal level, the Federal Aviation Administration (FAA) manages UAS authorizations. Under current rules, two methods exist to gain FAA authorization to fly nongovernmental commercial UAS: 1) Grant of exemption with a Certificate of Waiver or Authorization (a Section 333 Exemption Petition), which is suitable for commercial operations in low-risk, controlled environments; and 2) Special Airworthiness Certificate, which is similar to the aircraft registration process for regular manned aircraft.

The FAA has granted about 5,300 Section 333 petitions to date; the approval process can take eight months or more. The exemption provides a blanket authorization for UAS use as long as several conditions are met, one of which is that the UAS is only operated by a pilot possessing at least a Sport Pilot Certificate (a commercial pilot’s license is not required). All owners of drones weighing between 0.55 and 55 pounds must register the drone with the FAA’s Unmanned Aircraft System registry before flying it outdoors. (Drones weighing more than 55 pounds are considered aircraft and must be registered with the Federal Aircraft Registry).

The FAA finalized new rules in June 2016 (effective in late August) that will simplify use of drones in small-scale applications, including requiring training in lieu of a pilot’s license. These new rules limit drone flights to a 400-foot altitude and speeds below 100 miles per hour, require visual-line-of-sight operation, limit operations to daylight hours, require minimum weather visibility of 3 miles and other similar constraints. In addition, a person operating a small UAS (below 55 lbs.) must either hold a remote pilot airman certificate with a small UAS rating or be under the direct supervision of a person who does hold a remote pilot certificate (remote pilot in command).

State and local regulations tend to be more focused on allowable hours of operation and privacy issues. Some municipalities have passed ordinances against UAS operations and lawsuits over drone operations are increasing, arising out of claims of trespass and invasion of privacy.

Drone imagery from New Earth’s composting facility in San Antonio, Texas generates data used to measure windrow volume and calculate

compost inventory.

Composting Case Study

New Earth is using UAS to measure windrow volumes at its flagship composting site in San Antonio, Texas. New Earth, a compost, soils and mulch producer, has three facilities handling about 500,000 tons/year of incoming materials. Because this is not a commercial application of UAS (i.e. New Earth is not providing the service to others), the drones can be used at their own sites. “We update our inventory monthly at all three sites, in order to verify our inventory estimates and determine how well our production operations are doing,” explains Clayton Leonard, CEO of New Earth. “Where we once had four staff people spending two days to update our inventory, we can now update inventory with just one staff person flying one drone. This has saved us time and money, and greatly reduced variations in inventory estimates. As you can imagine, if you have four different people estimating the height of a pile, you’ll get four different estimates.”

The drone automatically flies a predetermined pattern to photograph all the piles at each of New Earth’s sites. Its 116-acre site in San Antonio has over 100 piles; the 40-acre site in Conroe (TX) has about 50 piles, and its 55-acre site in Katy (TX) has about 20 piles. The photo above shows the imagery from a flight over the San Antonio site. Combining that aerial imagery data with global positioning system coordinates allows New Earth to construct a three-dimensional image of each pile, which can be input to a software program like AutoCAD. The software then calculates the volume of each pile.

New Earth uses a model eBee drone made by SenseFly, which it purchased from RDO Integrated Controls, a local distributor of UAS, lasers, levels and theodolites and other mapping, scanning and construction equipment. The unit is priced in the $30,000 range. “We get about 25 minutes per flight out of each battery pack and with three packs, we can fly for about an hour and a half, which is enough to map any one of our sites,” Leonard notes. The eBee, weighing 1.5 lbs (700 g), can cover up to 4.6 square miles (12 km2) in a single automated flight, while flights over smaller areas, flown at lower altitudes, can acquire images with a ground sampling distance (GSD) of down to 0.6 inches (1.5 cm) per pixel. The drone comes equipped with a high-resolution color digital camera and a carrying case.

To initiate a flight, the operator chooses or creates a background map to define the region to be mapped. The operator then specifies the desired ground resolution and the required image overlap. The drone software automatically generates a full flight plan, based on GPS waypoints, calculates the eBee’s required altitude and displays its projected trajectory on the monitor screen. To start the flight, the operator shakes the drone three times to start its motor and throws it into the air.

To meet New Earth’s data needs, the drone software must convert the image to a point cloud. These are comprised of millions of individual points, each featuring X, Y, Z coordinates and a Red-Green-Blue (RGB) value. This data can also be classified for more specific analysis, e.g., ground, buildings and vegetation. These analyses produce a Light Detection and Ranging (LiDAR)-like output (except in the presence of ground-obscuring vegetation), which are most often used for geometric and CAD-based work, like volumetric calculations of stockpiles.

“We are just learning how to use this new tool,” notes Leonard. “I’m interested in learning more about how we can use it. For example, if we put an infrared camera on the drone, can we fly it over piles and look for hot spots?”

For composters who track inventory value, this advanced technology would likely pay for itself fairly rapidly. And if it can be used to help manage operations — such as searching for hot spots that could lead to spontaneous combustion in mulch and compost piles — drones could become an invaluable tool in the toolbox.

Craig Coker is a Senior Editor at BioCycle and a Principal in the firm Coker Composting & Consulting (www.cokercompost.com), near Roanoke, Virginia. He can be reached at ccoker@jgpress.com.