BioCycle February 2019

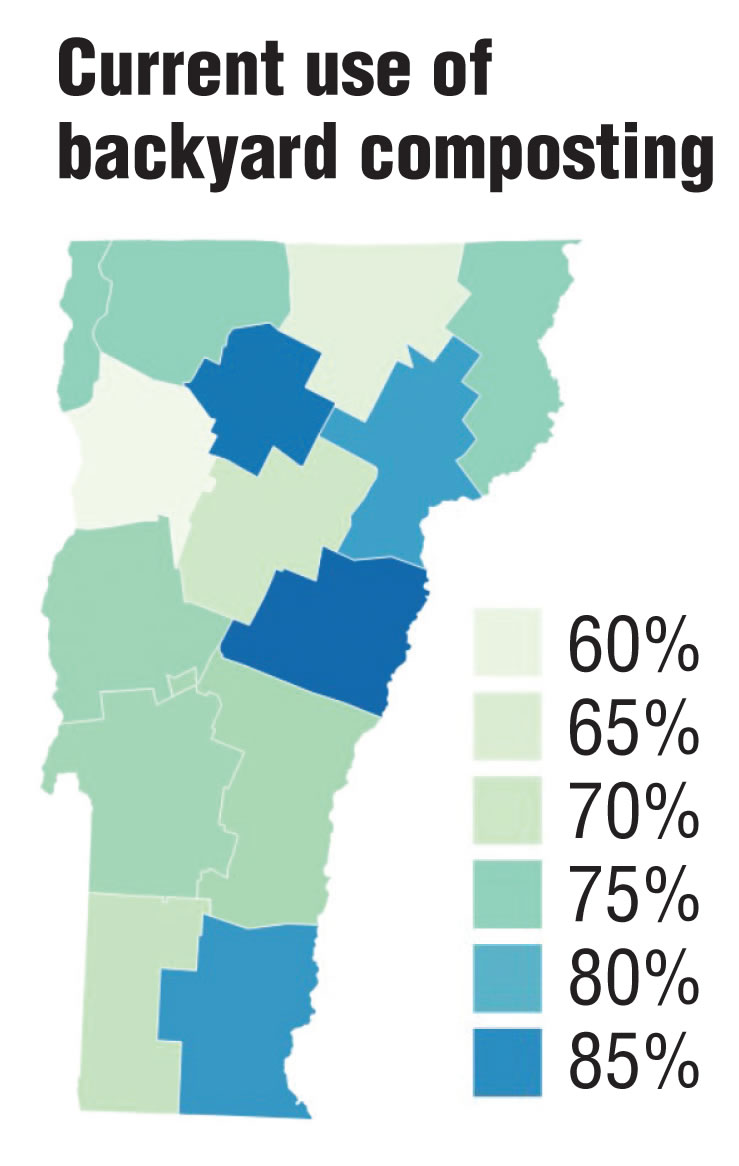

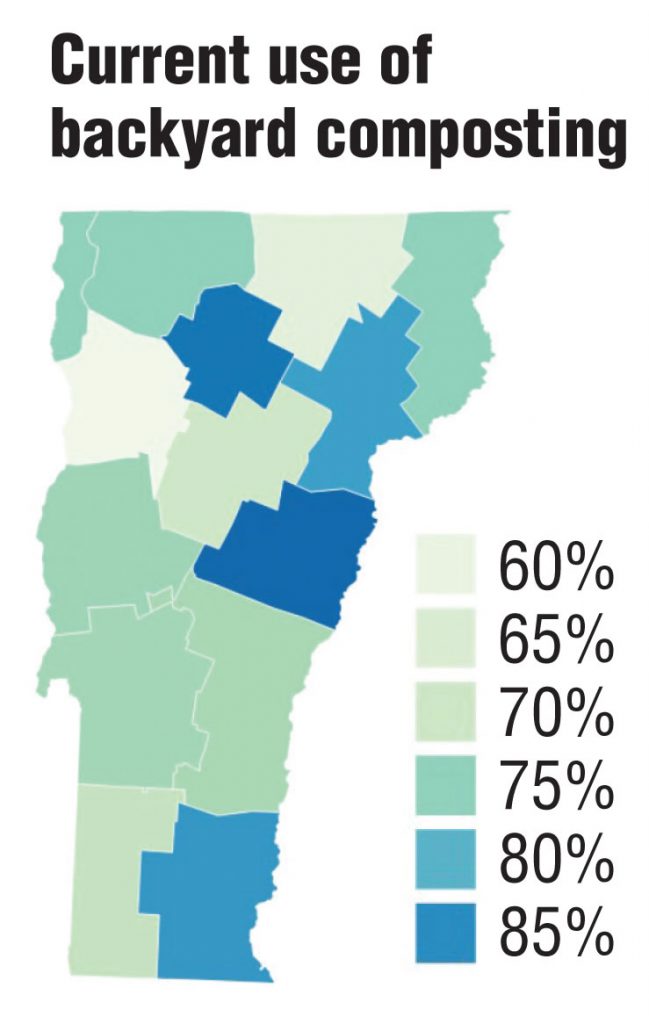

Burlington, Vermont: Home Composting Is Top Food Waste Management Strategy

A 2018 survey of 583 Vermont households conducted by Meredith Niles, a professor at the University of Vermont, found that the majority of respondents (out of a total of 583 households) currently manage their own food waste through backyard composting or feeding food waste to pets or livestock (72.4% of respondents). For future food waste management strategies, 76 percent of respondents are likely to manage their own food waste through backyard composting to comply with Vermont’s food waste disposal ban (Act 148), effective in 2020. The study results have a margin of error of plus or minus 4.1 percent, with a confidence level of 95 percent.

A 2018 survey of 583 Vermont households conducted by Meredith Niles, a professor at the University of Vermont, found that the majority of respondents (out of a total of 583 households) currently manage their own food waste through backyard composting or feeding food waste to pets or livestock (72.4% of respondents). For future food waste management strategies, 76 percent of respondents are likely to manage their own food waste through backyard composting to comply with Vermont’s food waste disposal ban (Act 148), effective in 2020. The study results have a margin of error of plus or minus 4.1 percent, with a confidence level of 95 percent.

Overall, respondents agree that food waste should be banned from the landfill (56.1% strongly or somewhat agree). A further 34 percent of respondents each suggested that they would be likely to subscribe to a curbside pick up program or continue to throw their food waste into the garbage (a practice that would technically be illegal). Less likely strategies include driving to a drop-off station (33% likely) and using the garbage disposal for food waste (20% likely).

Lewiston, Maine: Nitrate Contamination From Biofilter

The Lewiston-Auburn Water Pollution Control Authority (LAWPCA) has operated a 15,000 tons/year biosolids composting facility using an enclosed agitated bed system since 1993. In 2013, LAWPCA became the first wastewater treatment plant in Maine to process solids through anaerobic digestion. The biosolids volumes decreased by 50 percent and the treated solids have proven excellent for direct land application. As a result, the Authority’s need for the composting facility lessened, and for approximately the past five years, it has been utilizing the available capacity to process wastewater solids from other communities.

In December 2018, LAWPCA decided to halt composting operations all together, but for a different reason. Some years ago, testing indicated elevated levels of nitrate in the groundwater beneath the composting facility’s biofilter. The biofilter had been in operation since 1993, with a liner installed beneath it. Liquids draining through the filter media are collected in a pump station and pumped back to the wastewater treatment plant. Monitoring wells down gradient from the biofilter have consistently recorded high nitrate-nitrogen levels since 2004, with 2018 data showing concentrations of 560 mg/L (down from 1,230 mg/L in 2007). The maximum contaminant level for nitrate in groundwater in Maine is 10 mg/L.

LAWPCA is working with the Maine Department of Environmental Protection (DEP) to determine the cause and possible mitigation measures. Ultimately, it appears that nitrate is leaking from the biofilter, through the liner and/or associated piping system. Further details cannot be determined without removing the biofilter, which will be done this year, to stop any further nitrate leaching.

Ashland City, Tennessee: Good Year For The Compost Company

The Compost Company took in 5,412 tons of organics in 2018, due in part to partnerships with Marriott Hotels, HCA Hospitals, the Nashville Farmer’s Market, Metro Nashville and Vanderbilt University. It also was named the US Composting Council’s Compost Manufacturer of the Year for 2018. Grant proceeds from the Tennessee Department of Environment and Conservation helped The Compost Company acquire a Brown Industrial food waste collection truck, a Rotochopper grinder and Komptech screen.

Reston, Virginia: Soluble Salts In Compost

The Composting Council Research & Education Foundation (CCREF), working with researchers from the University of Wisconsin Oshkosh, examined soluble salt concentrations in compost. The final report, “A Review of Soluble Salts In Compost,” was released in January and provides a literature review of soluble salt concentrations and the effects of applying composts with high concentrations of soluble salts on plant growth and soil. Major findings from this review are:

- Presence of high concentrations of soluble salts in growing media can lead to phytotoxic effects. The most common soluble salt responsible for these effects is sodium chloride (NaCl). Good quality composts contain limited amounts of sodium ions (Na+) and chloride ions (Cl-), and therefore, should not cause the phytotoxic effects as long as they are properly applied.

- The literature suggests that application of compost with high electrical conductivity (EC) values and limited NaCl concentration will not induce negative effects as long as the soils they are applied to do not exceed an overall EC of 4 deciSiemens per meter (dS/m) after application. If the EC does exceed 4 dS/m, the recommendation is to irrigate the soil to leach excessive salts. As well, composts should not be limited to an EC value of 5 dS/m or less. The literature suggests that the application of composts with high EC5 values can be beneficial to plant growth and yields when properly applied.

- Measurement of EC values for soils and composts needs to be standardized. This can be done via the US Composting Council’s Seal of Testing Assurance (STA) guidelines for laboratories doing compost analysis through that program.

- Composts with high concentrations of soluble salts are effective at remediating saline-sodic soils by inducing the leaching of NaCl from the soil.

The report recommends standardizing the labeling of composts with high concentrations of soluble salts and include an agriculture index to inform consumers of the nutrient content and potential risks if improperly used. Regional and local soil management strategies for compost application should be developed with the variability of soil type, plants being grown, availability of irrigation, and environmental impacts in mind. Further research is needed to evaluate the different mixtures and proportions of soluble salts present in compost and their effects on plant growth.

Sacramento, California: Technical Assistance For Healthy Soils Initiative

California’s Healthy Soils Initiative, established under a broader short-lived climate pollutant greenhouse gas reduction law (SB 1383), received a financial boost last fall when former Gov. Jerry Brown signed AB 2377, Technical Assistance for Climate Smart Agriculture, into law. The bill requires that 5 percent of the annual budgets for the State Water Efficiency and Enhancement Program (SWEEP), Alternative Manure Management Program (AMMP), and Healthy Soils Program are used to establish a technical assistance grant program at the California Department of Food and Agriculture (CDFA). CDFA can provide grants of up $100,000 annually, for up to three years, to technical assistance providers like Resource Conservation Districts, Cooperative Extension and nonprofits to support SWEEP, AMMP, and Healthy Soils farmer applicants. Under AB 2377, technical assistance includes program outreach, project design, application assistance, project implementation and reporting. Technical assistance for small and moderately scaled farms and ranches is prioritized. According to the California Compost Coalition (CCC), the technical assistance “is needed to double down on compost use by 2025. The COMET-Planner was developed by the USDA to model the use of compost with 5 metric tons of carbon set to be reduced by 2030.”

Prince William County, Virginia: Composting Facility Groundbreaking

The Prince William County Board of Supervisors awarded a contract in 2015 to Freestate Farms to run its Balls Ford Road Yard Waste Compost Facility in Manassas, as well as build an advanced composting facility to improve the county’s ability to process yard trimmings, as well as the capacity to compost food waste streams. “This is a public-private partnership with Freestate Farms, which is going to finance, build and operate the facility,” explained Tom Smith, the county’s solid waste division chief at a groundbreaking ceremony for the new facility in December. “It’s all private money involved. There are no county funds. We’re able to do this pretty much at the same cost per ton that we’ve been processing yard waste out here for over 20 years.”

Yard trimmings and food waste currently constitute about 30 percent of the waste that is delivered to the landfill. In addition to yard trimings, the new facility will take food waste largely from grocery stores, restaurants, schools and other institutions and reroute it to the composting facility, Smith said. Freestate Farms selected Engineered Compost Systems technology for the new facility, and will use a series of concrete bunkers and pipes to continuously aerate the piles. A second phase planned by Freestate Farms is to add an anaerobic digestion facility to process food waste. The project is expected to be complete by 2020.