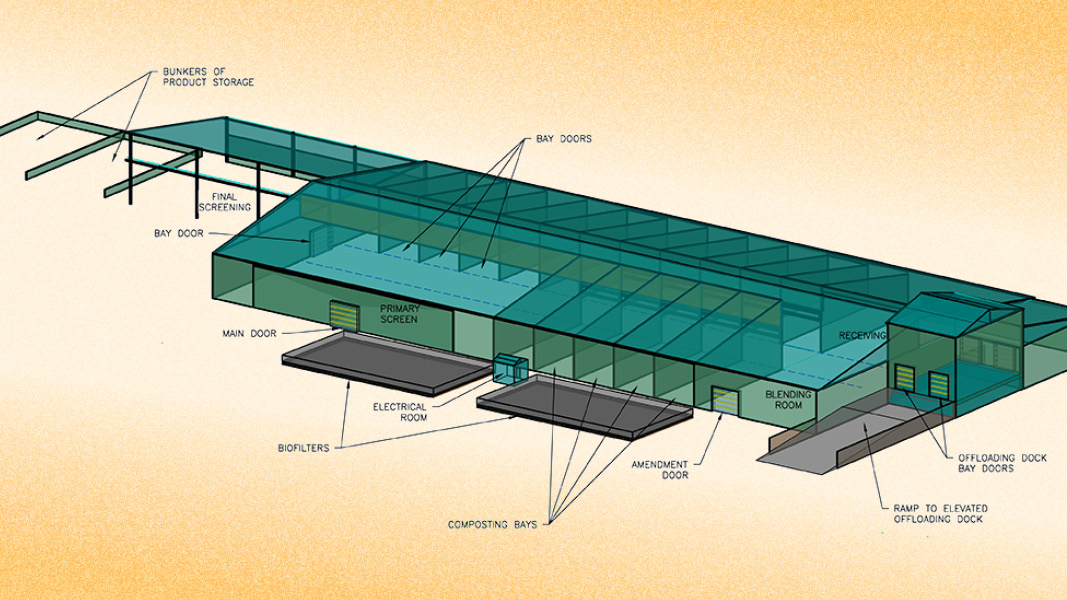

Top: Conceptual model of Fairless Hills (Falls Township, PA) facility. Images courtesy McGill Environmental Systems of NC

Almost three years after submitting its application to the Pennsylvania Department of Environmental Protection (PA DEP) for a composting permit to process a range of materials, including food waste, biosolids, and yard trimmings, McGill Environmental held a groundbreaking to begin construction of a 130,000 tons/year facility in Fairless Hills, located in Falls Township, Pennsylvania. “McGill received an individual permit from PA DEP to compost a variety of feedstocks,” explains Kate Sullivan, a project manager at McGill. “The facility is being built on a 15-acre site leased from WM, which has been composting yard trimmings there for many years. In addition to the indoor facility, McGill will continue composting the yard trimmings already going to the site as well as additional amendment materials from municipal and commercial sources.”

McGill’s other large-scale facilities, including its Merry Oaks site in New Hill, NC, are not fully enclosed.

McGill has been designing composting facilities for over 25 years, and the new facility represents the culmination of decades of experience and technical improvements. The Fairless Hills facility is completely enclosed — including the tipping floor and feedstock mixing area. (Its other facilities, all located in the Southeast, are not completely enclosed.) The building will house 20 individually controlled aeration bays. “Basically, waste materials go into the building and come out as product,” notes Sullivan. “We utilize positive aeration. Our latest innovations in wireless monitoring and control of temperature and air flow give the facility the highest level of process and odor control. All building air is treated through a biofilter.”

The Fairless Hills site, McGill’s first in the Northeast region, will be the fourth company-owned facility processing in excess of 100,000 tons/year. “Paying attention upfront to mitigating odors before they are a concern is our primary reason for having a fully enclosed operation that is as tight as possible,” she adds.

Products manufactured at the facility will be sold in bulk to the landscaping, sports turf, construction, agriculture, and erosion control industries. McGill participates in the US Composting Council’s Seal of Testing Assurance (STA) Program, which dictates product quality standards and testing requirements. The facility is expected to be operational by the end of the first quarter of 2024. “We believe this facility represents a real step forward for composting infrastructure and will make a meaningful contribution to organics recycling, carbon dioxide emissions reduction, and carbon sequestration,” says Noel Lyons, McGill Environmental’s co-founder and president.