Top: Tortuga Bay Puntacana Resort Club. Inset: Food waste being added to composting system. Photos courtesy Jake Kheel

Juliana Beecher

On the easternmost tip of the Dominican Republic, Grupo Puntacana (GPC) operates its many businesses with a commitment to sustainability. Founded on land purchased in 1969 by Ted Kheel, a New York lawyer, and his partners, Puntacana Resort now features three hotels (with a fourth in construction), almost 20 restaurants, 45 holes of golf, 2,000 private residences, a shopping mall, a tennis club, a polo club, and the country’s largest international airport. Social and environmental projects in the region are supported by the Puntacana Foundation, including a zero waste program that began in 2007 and was featured in a 2011 BioCycle article by Jake Kheel, GPC’s Vice President for Sustainability.

The GPC manages waste from international flights to the Aeropuerto Internacional de Punta Cana, as well as prepares meals for airport employees and the airlines.

In 2007, the Dominican Republic had no national waste laws and GPC was spending nearly $200,000 a year on hauling waste to open pit landfills. After an audit to determine potential savings from waste reduction and recycling, GPC’s journey toward zero waste began at the airport, with a new Center for Recycling and Incineration (CRI) to manage waste from international flights. At first, baled recycled materials had to be sent four hours away to Santo Domingo to reach a market, but the CRI’s activities quickly sparked a local market. Waste sorting into recyclables, organics, and trash was implemented at the resort’s hotels, restaurants and private residences. Food scraps were sent to pig farms or vermicomposting run by the Puntacana Ecological Foundation.

GPC’s waste valorization center, CENVAREE, uses a third-party company to manage the sorting and selling of recycled materials. Photo courtesy Puntacana Ecological Foundation

Evolution Since 2011

In October 2020, the waste management landscape in the Dominican Republic changed with the promulgation of Law No. 225-20 — General Law of Integral Management and Co-processing of Solid Waste. The passage of the law was partly spurred by an enormous fire in April 2020 at the Duquesa landfill outside of Santo Domingo, the largest open-air landfill in Latin America and the Caribbean. The scale of the fire raised awareness of the risks of poor waste management in a country dependent on tourism. In addition to promoting waste reduction and establishing waste management violations, Law No. 225-20 created a trust fund to incentivize the “valorization” of waste. Businesses and individuals are mandated to contribute annually to the fund, with amounts based on revenue or income. Government-authorized waste valorization centers are paid out of this trust fund for every ton processed, as long as at least 10% of incoming materials are “valorized” via recycling, composting, anaerobic digestion, etc. The law also established the Department for Integral Waste Management within the Ministry of the Environment and Natural Resources and started the process of closing the country’s roughly 250 open pit landfills, to be replaced by regional sanitary landfills.

Jake Kheel was part of a group working to get the solid waste law passed. GPC’s CRI has since become the Center for Valorization of the East (CENVAREE), an authorized waste valorization center. Once final validation steps are completed, GPC will start getting paid per metric ton of waste diverted from landfill out of the DO Sostenible — the trust fund established by Law No. 225-20. CENVAREE currently processes about 25 metric tons (28 tons)/day of waste from its various operations using an automated sorting line to remove recyclables and organics that were not source separated, followed by manual sorting of recyclables — both what comes from the automated line and source separated recyclables. Any organics removed during sorting are sent to composting. A third-party company manages the sorting and selling of recycled materials. Kheel hopes to optimize the current operations, and then open CENVAREE to accept waste from offsite sources, providing a service and adding a revenue stream. The Puntacana region is now served by one private sanitary landfill almost an hour away. The municipal and federal governments stay out of negotiations between private companies, and that monopoly has driven up hauling and tipping fees, so the resort stands to save even more by diverting as much waste as possible.

Operations at the airport also have changed. The CRI was originally built in part because of a legal requirement to incinerate the “hazardous” waste coming off international flights at the passenger and cargo terminals. This is standard practice at international airports to keep biological organisms like pathogens, microbes, and pests from spreading country-to-country. In 2022, the waste stream from the airport had outgrown the original incinerator. Rather than building a second, larger incinerator, GPC installed an autoclave to sterilize waste, which has become a common practice at other airports. The autoclave has reduced operating costs and emissions. Sterilized waste is landfilled, with the exception of easy-to-separate recyclables.

Food Waste Reduction, AD And Composting

Grupo Puntacana’s businesses have ample organic materials, with green waste from landscaping, manure and bedding from a 100-horse polo farm, and food scraps from restaurants, residences, and two commissary kitchens — one that feeds roughly 2,500 employees at the resort, and the Caribbean Catering Service, which feeds airport employees and makes food for flights.

A HomeBiogas biodigester was installed at a beachfront restaurant as part of a solution to decentralized food waste management.

It became clear early on that the original vermicomposting operation would not be able to handle all of the organic materials generated, so Kheel began looking into other options. In 2021, GPC received a grant from the Inter-American Development Bank for organic waste management. The grant funded a HomeBiogas biodigester as part of a solution to decentralized food waste processing. The biodigester was piloted and is still in use at a beachfront restaurant that’s off the normal waste collection route, however the approach didn’t take off resort-wide.

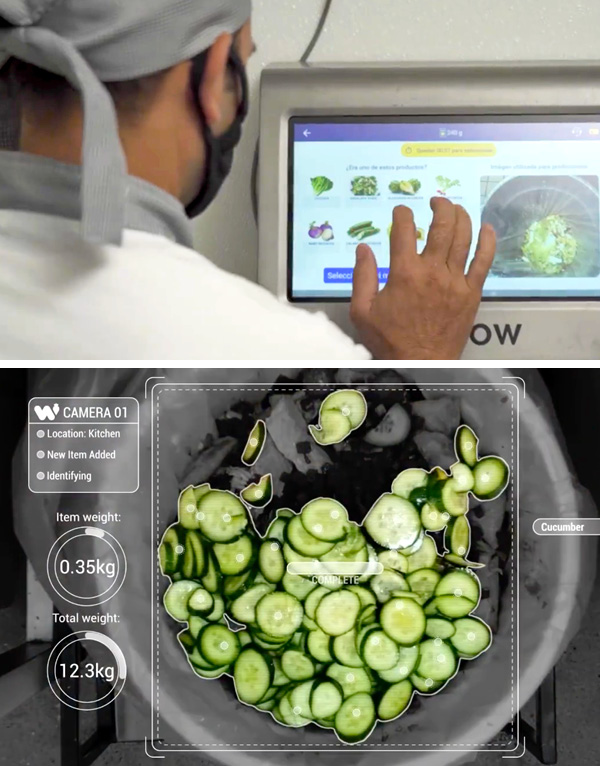

The Winnow food waste reduction system was installed in four of GPC’s largest kitchens. Images courtesy Puntacana Ecological Foundation

The IDB grant also provided funds for GPC to install the Winnow food waste reduction system in four of its largest kitchens: the three hotels and the airport commissary, known as B747. Winnow’s program uses a scale, camera and an AI-powered tool to weigh, photograph and identify food waste as it’s added to a bin. Winnow’s software assigns dollar values to food items so kitchen and zero waste staff can track the cost of food that’s wasted. All kitchen and plate waste is measured. “With a money value assigned to it, it’s not just the eco guy saying, ‘hey, we need to really cut down on the food waste to save the planet’,” notes Kheel. “It’s like, ‘hey guys, in the case of B747, we’re producing $2,500 a week of food waste because of spoilage, because of portions that are too big of certain things, or … bad prep practices or whatever’.” The kitchens using Winnow have made changes to portion sizes and the amount of certain foods prepped for a meal. Winnow also provides ideas for modifying menus to reuse certain ingredients for other meals.

Private residences have been the least compliant with waste sorting, adds Kheel, especially the short-term rentals. GPC uses the Recollect app to encourage sorting, and remind residents about recycling collection on specific days.

The COVID-19 pandemic disrupted the resort’s and airport’s waste operations. Tourism plummeted, revenue dropped, and voluntary initiatives like recycling were cut. GPC has a goal of 70% to 80% landfill diversion, and “we got pretty close at one point before the pandemic,” says Kheel. Utilizing pig farms to manage food scraps was a significant piece of that. But around the time of the solid waste law passing, and the IDB grant, reliance on pig farms was reevaluated. The zero waste team visited all the farms in the region to observe how they operated, and realized that food scraps weren’t getting fed to pigs until two or even three days after being collected, increasing health risks. “It became obvious that giving food waste from hotels to pig farmers without some kind of regulation in the middle could be pretty problematic,” explains Kheel. Now, the only pig farm that receives food scraps from the resort is onsite.

Seeking an alternative to pig farms for food waste management, Kheel attended the US Composting Council conference in 2022 and took a workshop on composting food waste led by Green Mountain Technologies (GMT). In conversations afterward, he shared the resort’s realities: a high volume organics stream, limited space for a composting operation, and the need for low odors to maintain a pleasant environment for tourists. GMT staff suggested its Earth Flow composting system as a possible solution, being fully enclosed, automated, and able to handle high volumes of food waste in a relatively short period of time.

Grupo Puntacana’s Earth Flow composting system is a custom design by Green Mountain Technologies and includes additional bays for curing and storage of finished compost, green waste and bulking materials, and enable future expansion (top). The system is designed for 1,500 to 3,300 tons/year. Photos courtesy Green Mountain Technologies

In spring 2025, a custom designed, site-built Earth Flow composting system was installed next to CENVAREE. Food and green waste are loaded into one end of a bay, aerated through channels in the floor and continuously turned by a steel auger. After two to three weeks, material is removed from the other end of the bay and cured for another six weeks before being used on the resort properties. Emissions vent through a biofilter to keep odors low. Additional bays are used for curing and storage of finished compost, green waste and bulking materials, and enable future expansion as needed. Currently, roughly 0.5-1.0 ton/day of food and green waste are being composted. The system is designed for 1,600 to 3,300 tons/year. Green waste is the limiting factor because palm fronds, which make up the bulk of it, need shredding before composting. Kheel estimates that about 300 cubic yards of green waste is generated per month (currently piled in an old mine). Adding more green waste into the composting system will allow for more food waste to be composted. Plans include installing a shredder this year. Horse manure from the polo farm is composted in eight aerated static piles, managed by the Puntacana Foundation.

On The Horizon

Sargassum seaweed is a challenge for the tourism industry all around the Caribbean and the Gulf of Mexico, washing up on beaches in huge, swathes. GPC is partnering with a local university to experiment with biodigesting sargassum. Using six HomeBiogas units purchased with grant funds from IDB, experiments were conducted with different mixes incorporating sargassum with food waste and manure. Sargassum is seasonal, so for six months of the year it’s not available as a feedstock. The university built larger biodigesters and continues to experiment with that solution. Meanwhile, GPC is continuing to support academic research on sargassum and experiment with other outlets like sending sargassum to a Finnish cosmetics company.

Grupo Puntacana has been at the forefront of resort waste management in the Caribbean since its founding. Reducing and sustainably managing waste for the resort, private residences and associated businesses are not only central to its mission and vision of environmental sustainability, but also to the guest experience. International tourists expect an easy, clean system for trash and recycling, similar to what they have at home. GPC is starting to build back toward the resort’s goal of 70% to 80% landfill diversion. The Earth Flow composting system is a big step toward zero waste. Of the 28 tons of waste currently generated daily, 2.3 tons are food waste — of which 0.3 tons are composted, with 2 tons fed to livestock. On average, 21 tons are sent to landfill, 2.8 tons are recycled, and 1.5 tons are incinerated. Kheel’s goal is to scale up to 110 tons/day for CENVAREE. Between the airport, resort, businesses and private residences, 45 to 55 tons/day would come from GPC’s properties, leaving capacity to accept organics from other businesses.

At this point, the zero waste operations are breaking even, but as composting scales up, GPC expects to turn a profit. Except for the third-party company managing the recycling line, everything is run in-house — from collection to research and development. Under consideration is buying a truck and self-hauling to the landfill to save on high hauling fees, or even building its own sanitary landfill in the future. With few external options, Kheel describes GPC as “hard-headed” about figuring out the right way to manage its waste and plan for being flexible should issues arise. “We’re trying to run a resort, we’re not trying to deal with garbage, really. We wouldn’t have gone this far if somebody just offered the service, but they didn’t, so we had to do this.”

Juliana Beecher, a Contributing Editor to BioCycle, is a former ORISE Research Fellow with the U.S. EPA’s Office of Resource Conservation and Recovery. Now working as a consultant based in Portland, Maine, Juliana brings the food waste perspective to broader food systems conversations and efforts to build a more resilient food supply chain.