With limited grant funds available, Pennsylvania corrections facility and technology provider find a way to build in-vessel composter within budget and in-house.

Dan Sullivan

BioCycle May 2012, Vol. 53, No. 5, p. 25

Amendment includes ground tree trimmings brought in from around the county (top), that are added as needed to balance out the nitrogen-rich food waste that comes from the jail dining hall (above).

“We wanted something that was easy to operate and didn’t require a lot of manpower,” says Brown. “We have a jail to run — we just dabble in recycling. The system we built has automated controls and takes up a small space.” The unit includes three 10-foot by 20-foot vessels that can be filled with feedstock up to 9-feet high. It has the capacity to process 3,000 pounds/day of institutional food waste. With an average inmate population of 1,050, jail personnel needed the system to be operational 365 days a year. The in-vessel retention time is 21 days, after which the compost is windrowed for another two weeks before being utilized at the jail farm and for landscaping and other county projects both on and off jail property. The putrescible food waste is stored in a designated walk-in cooler prior to transport (weekly) to the composting facility.

The Berks County Jail metal shop built an ECS stationary in-vessel composter with plans, components and encouragement from the manufacturer.

That was early in 2008. Diddy didn’t hear much from Berks County “until about four months ago, when we got a call from the jail and they said the SV Composter was ready for start-up,” he says. “Sure enough, they had been diligently building the vessels and making all the components in their shop and following our drawings. So we sent Chris Hibbard, ECS Senior Project Engineer, out there last month to start up the system and train the staff. It’s now fully functional and running.” Brown says the project came in at about a third of the cost of having it built by an outside contractor. Ultimately, she notes, the jail was able to utilize $100,468 of the grant funds, which also included purchase of a dump truck and other tools necessary for processing compost. Maintenance Officer Kenny Heffner with assistance from Maintenance Officer Marc Speece, navigated the plans, fabricated the equipment and constructed the vessels.

Design And Operation

The SV Composter has 100 percent capture of fugitive emissions; about 80 percent of the process air is recirculated with the balance sent to a biofilter for scrubbing. The vessel walls and ceilings are well insulated as are the doors. All doors exposed to the process air are stainless steel, and all other components in contact with the compost’s corrosive airstream are made with either stainless steel or polymeric material. There is an in-floor aeration system, and condensate/leachate is collected in the aeration floor and drained into a sealed sump. The SV Composter is operated as a batch system.

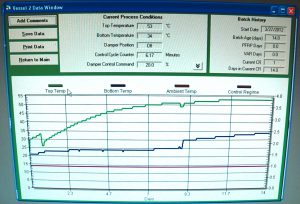

An automated aeration control and monitoring system enables the operator to compare relative progress of the material in each bay and make necessary adjustments.

Currently, the composting vessels sit just inside the chain-link fenced and razor-wired secure perimeter of the jail. Plans are to move the fence line so that the building is just outside that perimeter, providing easier access to county employees bringing in carbon-rich materials. Green waste is ground into chips, and mixed in with the food waste using a skid loader. “All meats that come out of the kitchen are put in the composter, too,” says Pajski, adding that food served but not eaten is diverted to composting as well. “Hot dogs, Salisbury steak, peas, carrots — whatever comes back, I get.” Each vessel is wide enough to accommodate a skid loader, dump truck or backhoe, making it convenient for loading and unloading the material.

Under Warden George A. Wagner’s watch, the Berks County jail has historically composted. “We have windrows on the jail grounds not too far from the composter that we still maintain,” adds Brown. “We utilize equipment [such as skid loaders] to turn the rows. We do not have a turner, and we do not plan to screen.”