Top: Preparation of food scraps to be added to the bins for processing. Photo courtesy of Lab/Cor Materials (Seattle)

Ron Alexander

A recent study processed a consistent mixture of food scraps in different electric household food scrap processing appliances, then through analysis of the output product, attempted to determine the extent to which the composting process or biological degradation had occurred, and whether or not the output product could be classified as “compost.” Further, it aimed to determine if the addition of the microbial “accelerator” inoculants used by some of these units significantly affects the characteristics of the processed food scraps.

Numerous food scrap processing appliances have entered the market over the past several years. Although the specific process (times, temperatures, moisture content, modes, etc.) varies from appliance to appliance, they can all generally be characterized as residential food scrap preprocessors. Some are designed as dehydrators, since they dry and grind the scraps added to them. Some of these appliances are marketed as “electric kitchen composters,” although the somewhat lengthy period of biological decomposition, characteristic of the composting process, does not occur within these units. All use an outside heating source during their processing.

Some appliance vendors provide users with microbial additives to combine with the food scraps at the start of a processing cycle, to attempt to speed up biodegradation or biologic stabilization of the organic matter. Historical data suggests that it may be impossible to drive the composting process to completion in under a few weeks (even in optimal conditions), thus there is scrutiny around whether a “compost” product could be produced during these units’ short processing cycles and in some units, under the harsh conditions of heating and drying.

Experimental Design

This study tested three food scrap processing appliances: Mill, Lomi, and Reencle. For appliances that recommend processing food scraps in combination with a microbial additive (Lomi and Reencle), two treatments were run — one where the additive was used as recommended and one without any additive used. For the other device (Mill), only a single treatment was run (no additive was used). Each treatment, with the exception of the Reencle appliance, consisted of adding 3.5 lbs. of food mix for four consecutive days. The Reencle unit received 2.2 lbs/day (maximum addition/day in the user manual instructions) for six days. With the Lomi device, four replicates were processed through the device (one at a time, where the output was removed after each replicate’s processing cycle), then the output from each replicate was combined before sampling for testing and a molding trial. For the larger units, Mill and Reencle, replicates were added for four consecutive days (one replicate added per day, without removing output between additions) for Mill, and over six consecutive days for Reencle.

A standardized mixture of food scraps for all the bins and replicates was produced at the same time. Once all of the replicates were assembled, they were stored in a freezer to prevent any changes in the food mix that might otherwise occur if stored in ambient conditions (such as moisture content or molding), until the day of processing. A few hours before adding to the appliances, the replicates for that day’s runs were removed from the freezer to allow them to thaw.

The Mill and Lomi devices are specifically designed to drive off moisture via heating the contents once the processing cycle begins. The Reencle unit appears to use outside energy to heat the food scraps during processing. The appliance also has a drying capability that can be activated via pushing a dry button on the appliance. It is unclear as to how much moisture is lost during the processing of the food scraps within the Reencle unit, before and after the drying function is engaged. That stated, it appears that the majority of moisture is driven off once the drying function is engaged. That is certainly what happened during the trial discussed in this article, and as directed by the user manual, the drying function was engaged to dry down the “boggy” (wet) feedstock.

A standardized, uniform mixture of food scraps samples were assembled at the same time. Photos courtesy of Lab/Cor Materials (Seattle)

All replicates were stored in a freezer to keep stable until the time of processing.

After processing, all replicates of the output from each treatment were aggregated into a single sample (one composite sample for each treatment) and held in cold storage before shipping. Samples were shipped overnight, on ice, to a compost testing lab (Soil Control Labs in Watsonville, California), where a full Seal of Testing Assurance (STA) program suite of tests was completed. Samples were also shipped to the author to complete a product molding trial. The STA program is the national testing and certification program for compost which requires ongoing analytical testing, focusing on a series of important compost parameters.

Results

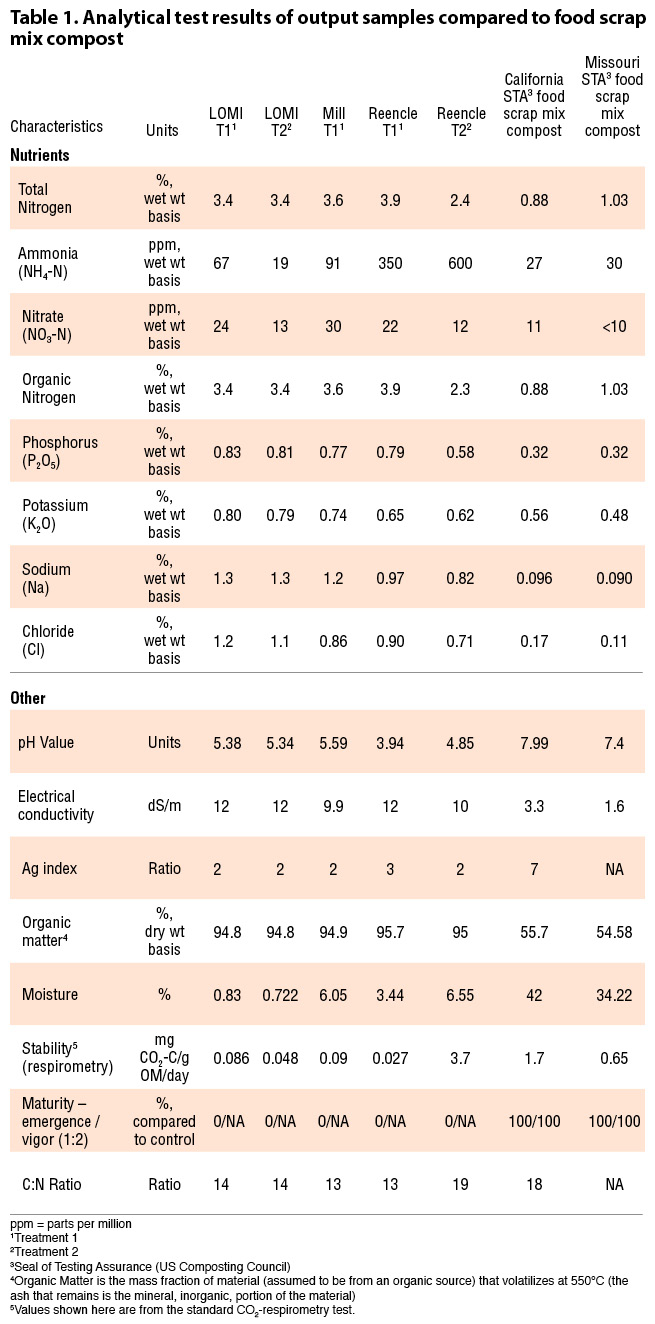

Product testing was completed to better determine, analytically, how the processed food scraps compare to and differ from a compost containing food scraps produced at a commercial composting facility (Table 1). Additionally, the testing was used to identify if significant differences existed between the materials generated through different food scrap processing appliances, as well as treatments using additives offered by certain appliance providers.

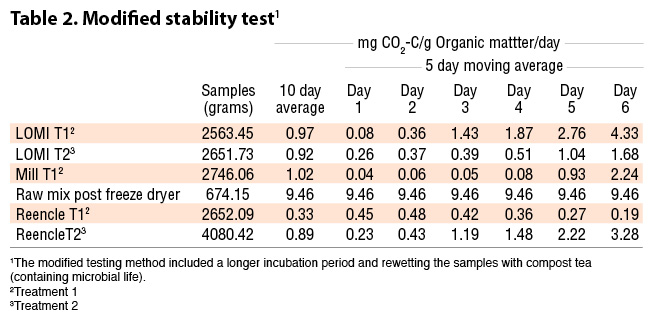

It must be noted that during the author’s 2023 trials (Alexander, 2023), processed food scrap materials gave a false indication of stability using the Solvita test (a field test which measures carbon dioxide (CO2) generation and ammonia release), but not the laboratory respiration test (a lab test which measures CO2 generation). During this trial, false indications of stability occurred while testing for microbial respiration. It is unclear why processed food scrap materials can fool these standard test methodologies, but it may have to do with the high moisture content and low porosity of the food scrap materials before they are processed, the extreme desiccation of microbial life during its processing, or some other limiting factor. That stated, using a modified respirometry method, all of the processed food scrap samples produced during this study illustrated an increased respiration rate after rewetting and upon further aging, an indicator that the material is not stable. (Table 2). This does not occur with properly biologically stabilized compost products.

It must be noted that during the author’s 2023 trials (Alexander, 2023), processed food scrap materials gave a false indication of stability using the Solvita test (a field test which measures carbon dioxide (CO2) generation and ammonia release), but not the laboratory respiration test (a lab test which measures CO2 generation). During this trial, false indications of stability occurred while testing for microbial respiration. It is unclear why processed food scrap materials can fool these standard test methodologies, but it may have to do with the high moisture content and low porosity of the food scrap materials before they are processed, the extreme desiccation of microbial life during its processing, or some other limiting factor. That stated, using a modified respirometry method, all of the processed food scrap samples produced during this study illustrated an increased respiration rate after rewetting and upon further aging, an indicator that the material is not stable. (Table 2). This does not occur with properly biologically stabilized compost products.

General Findings

Total nitrogen content in the processed food scraps is high, compared to compost containing food scraps produced at commercial composting facilities. This is because there is no wood bulking agent (carbon) added to the feedstock, which is done in “actual” composting. The carbon addition dilutes the nitrogen content. For the same reason, the C:N ratios of the resulting materials are low. Therefore, C:N ratio cannot be used as an indicator that the product is biologically stable. It should be noted that the Reencle Treatment 2 (T2) material, which contained a significant volume of its microbe additive (added at the recommended application rate) and which uses wood pellets as the carrier, contained the lowest content of nitrogen and other key nutrients. This was likely caused by dilution from the addition of carbon contained in the wood pellets. It also had the highest ammonia content of any of the materials. Reencle T2 (with microbes added) had lower nutrient content (except for a higher ammonia content) than the Reencle Treatment 1 (T1). Lomi T2 (with microbes added) had less ammonia and nitrate nitrogen than the Lomi T1 treatment.

Outputs processed in the Lomi and Mill appliances were extremely low in moisture content (all under 7% moisture and 3 were at 1% and below), which is restrictive to microbial growth. Research completed by the University of Georgia (Liang, et al., 2003) has shown that reducing moisture content to even 30% to 40% drastically reduces microbial activity during composting. For the Reencle unit, the processed food scraps became dry after the drying function was employed.

All processed materials exhibited very low pH values, with Reencle T1 being the lowest (3.94) and Mill being the highest (5.59). In actual composting, these low pH values are indicative of early stages of the process and reverse quickly. However, with the electric food scrap processing units, low output pH values (less than that of the raw food mix) may be caused by the high moisture content and low porosity of the food scraps, causing anaerobic conditions, before processing (drying) begins.

All processed materials possessed very high levels of sodium (0.82% to 1.3%) and chloride (0.71% to 1.2%), as well as electrical conductivity (9.9 to 12 dS/m). This would make the materials difficult to use at typical compost product application rates without resulting in salt damage or toxicity to various plant species.

Molding occurred at the analytical lab while testing the maturity of the materials. All samples grew mold in the same way this sample did. This does not occur with true compost. Photo courtesy of Soil Control Labs

Like in earlier trials, most of the materials processed in the kitchen appliances grew excessive amounts of mold during the molding trials completed by the author. In this trial, samples were wetted and then placed in a covered seed germination greenhouse, so they could stay wet. Interestingly, during the 2-week maturity testing at Soil Control Labs, all of the growing media containing one-third by volume of the various processed food scrap materials molded throughout the media. This further indicates that the appliance-processed food scraps are not biologically stabilized compost.

The use of the microbial additives in two of the processing units (Reencle and Lomi) did not appear to significantly impact material quality or stabilization.

Indicators Distinguishing Processed Food Scraps Vs. Compost

Indicators that the processed food scraps are not compost or biologically stable include:

- Very high organic matter content. Most actual composts contain 60% organic matter or less. This is because the more volatile (biologically reactive) organic matter is readily broken down by microbes during the composting process.

- Extremely low moisture content in dehydrated food scraps. Best management practices in composting call for a 60% moisture content at the start of the process and 40% to 50% moisture content at the end (in the finished compost). Further, adding water throughout the process is often done to optimize microbial activity, which improves the efficiency of biologic degradation (stabilization).

- Very low pH (less than that of the raw food mix). Very low pH is likely not caused by the pH of the feedstocks. Instead, it may indicate anaerobic conditions within the early stages of processing, before the material is even dried down.

- Extensive molding. Since soil microbes haven’t degraded the volatile organic materials in the feedstock, mold uses it as a nutritional source and grows aggressively and with little microbial competition.

- Extensive odor generation. When applied to the top of soil/media, the product typically attracts vermin. Flies were attracted to the samples during the molding trial after they were placed outdoors after two weeks.

Flies were attracted to the samples during the molding trial when they were placed outdoors. Photo by Ron Alexander

These characteristics of processed food scraps are negative parameters to plant growth, especially when used at common compost application rates:

- High sodium and chloride content (4 to 5 times higher than compost containing food scraps). This leads to high electrical conductivity and poor maturity results. It can be deleterious to many plant species and especially seedlings and germinating seeds.

- Mold growth. Mold will compete with plants for resources and will sometimes even smother them if they are small seedlings.

- Rapid degradation in the soil/media. Unstabilized organic matter (rich in volatile solids) added to soil in significant volumes can aggressively degrade in the soil/media. The potential impact is soil volume shrinkage and high oxygen demand which can negatively affect plant growth.

Stability and maturity indicators are unreliable when evaluating household kitchen appliance-processed food scraps because:

- Low C:N ratio. Appliance-processed food scrap C:N ratios may be low (under 15 or 20:1), not because of microbial degradation of the carbon (like in true composting), but because the C:N ratio of the starting feedstock simply starts at that low ratio.

- Low respiration rate. Results from standard respirometry and the Solvita tests may show low evolved carbon dioxide of the appliance-processed food scraps, not because the material is biologically stable, but because existing microbial life at the beginning of the test has been virtually eradicated or for some other unknown reason. This needs further investigation. That stated, using a modified respirometry method, all of the processed food scrap samples produced during this study illustrated an increased respiration rate after rewetting and upon further aging. This does not happen with properly biologically stabilized compost products.

Conclusions

It is clear that food scrap processing units, often referred to as “electric kitchen composters,” are not miniaturized composting units. None of the units utilize processes that fit the traditional definition of the composting process, and, more importantly, the processed materials do not possess the characteristics of a biologically stabilized compost (e.g., low odor when wetted, does not mold, has gone through significant organic matter loss). Further, based on analytical data generated through this study, it does not appear that the additives offered by certain unit manufacturers to enhance biologic degradation are overly effective.

While these appliances can dry down and stabilize food scraps for transport and further management, the resulting materials are not biologically stable, as illustrated by their odor, molding, vector attraction, and increased respiration rate (CO2 generation) upon rewetting. Further, it is unlikely that the resulting materials can be applied and utilized in the same versatile fashion as actual compost products, or with as little potential nuisance. This is not to say that the resulting materials cannot be utilized if further stabilized. But without further stabilization, they should be used conservatively and with caution. Note, based on analytical testing, the materials are likely to possess a significant soluble salt content which can negatively affect seed germination and plant growth. Often these materials also fail standard stability analyses.

Additional research should be completed by food scrap processing appliance companies to:

- Provide more detailed instructions on the efficacious application of their products,

- Better explain how to appropriately stabilize the processed food scraps before usage, and/or

- Offer alternative uses for the processed materials.

Further, additional research is needed to understand why standard compost test methods for stability (respirometry) and maturity (Solvita) do not always work appropriately with these materials.

Ron Alexander is a horticulturist and president of R. Alexander Associates, Inc. (Apex, North Carolina), a company specializing in product and market development for organic recycled products. He is author of ”The Practical Guide to Compost Marketing and Sales” (2nd Edition published by BioCycle) and has over 40 years of experience in compost and recycled organics product development and marketing. Mr. Alexander is an Industry Liaison to AAPFCO (Association of American Plant Food Control Officials) and completed research during his tenure in college and after, working with university researchers and public and private testing laboratories.