Top: Wasatch Resource Recovery facility in Salt Lake City, Utah.

Nora Goldstein

Starting November 5, Momentum Recycling will begin collecting residential food waste weekly from up to 100 households in the Liberty Wells neighborhood in Salt Lake City, Utah. “It is a free 3-month pilot funded by a grant from Intermountain Healthcare that begins November 5 and ends on January 28,” explains Lexi Passmore, Momentum Recycling’s Marketing Coordinator. “Our goal is to see if we can offer this service on a permanent basis. We will be assessing the level of participation, the households’ willingness to pay for the service after the pilot, and the amount of food waste diverted from the landfill.”

To gauge interest in food waste collection, Momentum Recycling conducted a survey of Salt Lake City households during the summer. “We initially were shooting for 50 households that would be interested in participating in the free pilot, and heard from about 720, all expressing interest,” adds Passmore. “In early October, an email was sent to households in the Liberty Wells neighborhood to sign up for the program and within a half-hour, 50 signed up.”

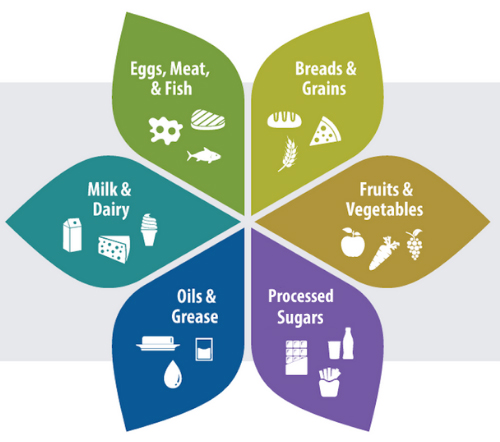

All food wastes are accepted, including fats, oils and grease. Households are receiving a 16-gallon cart, a 2-gallon kitchen caddy, and a supply of BPI-certified compostable liner bags for the caddy. Participants will be notified in mid-January if Momentum Recycling will continue collection after the pilot period. If it is continued, the monthly service fee will be $20/month. About 90% of survey respondents indicated they would be willing to pay for the service.

Participating homes receive a 16-gallon dedicated food waste collection cart for the pilot. Photo courtesy of Momentum Recycling

Collection will be done primarily using a Dodge pickup truck with a Satellite 8-cubic yard unit mounted in the truck bed. Residential food waste will be taken to Wasatch Resource Recovery (WRR), which operates an anaerobic digestion facility adjacent to the South Davis Sewer District’s wastewater plant. Momentum Recycling currently brings food waste collected from commercial and institutional accounts (including Intermountain Healthcare) to the Wasatch digester. It offers both cart and dumpster-based collection containers. “The WRR facility can tolerate up to 7% contamination in the food waste loads,” says Passmore.

Wasatch AD Plant

The Wasatch Resource Recovery anaerobic digestion facility in North Salt Lake City began receiving food waste in 2019. It operates under both wastewater and solid waste permits. The facility includes two 2.5 million gallon continuous stirred tank reactors (CSTR), a tank to receive fats, oil and grease (FOG), and a hydrolysis tank that feeds the digesters, which operate at mesophilic temperatures. The first phase of the project is designed to process 180,000 tons/year of source separated organics; the second phase will increase the capacity to 250,000 tons/year. Phase I is rated to generate up to 3,000 dekatherms a day of renewable natural gas (RNG). “We began injection into the Dominion natural gas pipeline, which is adjacent to the plant, in December 2020,” notes Elizabeth Barrett, WRR’s Procurement Manager. “Currently, we are receiving around 400 to 450 tons/day of various food waste streams.”

The Wasatch Resource Recovery (WRR) AD facility (foreground) is adjacent to the South Davis Sewer District wastewater treatment plant. Facility overview photos courtesy of WRR

The WRR project is a joint venture between ALPRO Energy and Water, a joint venture between Alder Construction and Aqua Engineers, and the South Davis Sewer District. Sewer District staff operates the WRR AD facility. Incoming food waste is received in four ways, explains Barrett:

- FOG from grease traps and a pig farm arrives in tanker trucks and is pumped into the FOG tank

- Liquids, e.g., milk, whey, meat slurry, brewery waste, from area food processors can go directly into the digesters

- A loading dock where pallets of boxes containing soda, milk cartons, cereal, flour, sugar, etc. are pulled off of trucks

- A tipping floor where garbage trucks tip loads of food waste

Commercial food waste collected by Momentum Recycling is tipped inside the WRR receiving building. Photo courtesy of Momentum Recycling

“Originally, when the facility was being designed, we anticipated getting more loads from restaurants, grocery stores and institutions that would be directly tipped inside the building,” says Barrett. “Therefore we have a large tipping floor. Loose food is an ideal feedstock and generates a lot of biogas. However we receive more packaged goods on the loading dock than anticipated, which is great, but requires more upfront handling.” She adds that a number of larger food manufacturers have operations in Salt Lake City. Those plants are a significant source of incoming food waste, as are many area grocery stores.

Packaged foods and food waste with contamination are processed through a Monsal ADT Re:Sep depackaging system, which has a vertical paddle mill and two sizes of screen mesh. The slurried feedstocks are routed through a hydrocyclone to remove grit and heavy inerts, then fed into the hydrolysis tank, which has a 3 to 5 day residence time. Feedstock from the tank is metered into the CSTRs for a 20- to 22-day hydraulic retention time. Because all the biogas is upgraded to RNG for pipeline injection, there is no source of waste heat. Instead, the reactors are heated by dual fuel (biogas and natural gas) boilers.

The biogas cleaning system is supplied by DMT Clear Gas Solutions, using the Sulphurex®BR regenerative technology to reduce hydrogen sulfide (H2S). Carbon dioxide (CO2) removal is done by DMT’s Carborex®MS technology, a dry membrane filtration system. Moisture is removed both by condensation and as an ancillary benefit of the CO2 membrane filtration system.

Digestate from the CSTRs is dewatered with a screw press. Solids are picked up twice a week and land applied by a farmer who is growing alfalfa. The effluent from dewatering is routed to the wastewater treatment plant next door. “Eventually, we may utilize the solids to make a soil product,” says Barrett. “The material is black and rich and resembles a compost. But we still have some kinks as small bits of harder plastic, typically from #5 polypropylene containers, are visible at times. We are evaluating options to remove these contaminants.”

Additional details about the Wasatsch Resource Recovery facility can be found in a 2017 BioCycle article by Craig Coker.