Ted Dirkx

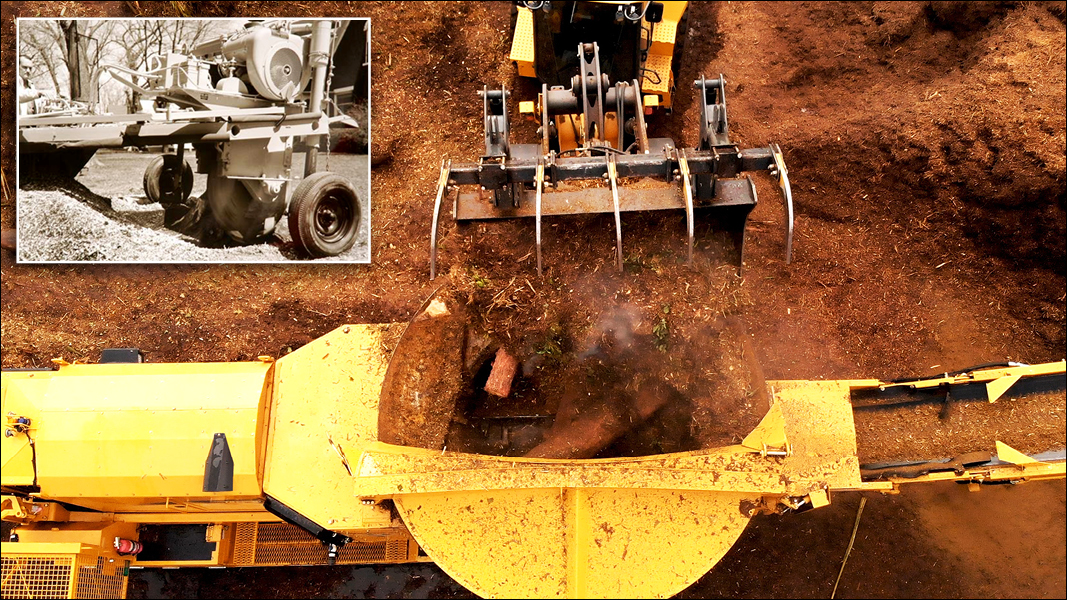

Top photo: During a test in 1953, an operator hit the wrong lever on a prototype Vermeer stump cutter (inset), causing the wheel to cut in an unintended direction. Since it cut five times faster, a new design was developed. Tub grinder in action (above). Photos courtesy of Vermeer Corporation

Whether you’re only getting into the composting business or you’ve been doing it for many years, one thing separates the companies that are successful from average producers —innovation. It links to everything else on your list of what makes a composting facility successful, e.g., efficient operations, a good team, and equipment that enables the facility to produce more products at lower costs.

Vermeer started as one Iowa farmer’s desire to find an easier way to unload a wagon in 1943. Company founder Gary Vermeer led with innovation, but it took thousands of innovators to build the organization to where it is today. This article translates how our experience with thriving on innovation can be translated to composting and organics recycling facility operators.

Step 1. Understanding Innovation

The word innovation gets used a lot, but if you sit down and define what change means for your company, it’s this: Innovation is the process of discovering unmet customer needs and then developing solutions to address them.

Innovation is necessary to continue to grow in the composting industry. It’s not luck when a producer uncovers a brand new customer base for its high quality, nutrient-rich compost. Instead it takes a savvy, innovative producer to seek out areas of opportunities and come up with the right compost mix to serve that market’s needs — and then creating and promoting that product to other potential customers with a similar set of needs.

New markets for custom blends of compost often lay within market segments you are not connected with like architectural, engineering, agricultural, and gardening sectors that have growing medium needs that are not being met. Engaging with these groups and asking open-ended questions about their challenges and then taking those back to your team of experts to brainstorm the possible solutions is how companies discover new innovative products they never knew existed.

Set the expectation for innovation to build and maintain your business as this market has a considerable need for innovators. The industry needs you to continue to look for better ways to make compost and expand its usage. From a less aspirational level, turning your operations from just focusing on incoming tip fees to focusing on the products you sell to end users takes work and being inventive. Seek out needs and develop the solution.

Step 2. Develop An Innovative Culture

When people think about innovative companies, typically one person within those organizations comes to mind, e.g., Henry Ford, Steve Jobs, Oprah Winfrey, Elon Musk. While these are all forward-thinking individuals, the idea of one person being responsible for innovation is a myth. These great innovators didn’t execute on their ideas alone. It took a team with the right company culture to unlock the innovation.

To establish an innovative culture, start by empowering your team — get them invested in the company’s or organization’s output and growth. Empowered employees share ideas and feel comfortable debating processes and ideas with their management in a positive way. Empowering your staff also means allowing them to research and explore ideas they believe can help the organization grow and better meet the needs of your customers. This process takes a long time to build into your organization’s culture. Your next big idea isn’t likely going to come from a brainstorming session during a planning meeting; it’s more than likely going to come from the break room over a cup of coffee.

To encourage your team to keep bringing you ideas, recognize those efforts regularly. Employees need to see that you value their input, whether their idea saved the company in operating expenses, expanded your customer base, or resulted in failure. Not every idea will lead to success. Also, there is a good chance a good idea won’t be a perfect solution the first time it’s implemented. It will more likely take several iterations before it becomes a widespread success.

The team at Vermeer understands that failure is part of success. When Gary Vermeer was testing a prototype of the first stump cutter in 1953, the operator hit the wrong lever, causing the wheel to cut in an unintended direction. The mistake cut five times faster and took the development team in a brand new direction. It’s this spirit of learning from failure that has continued to drive design innovation for decades.

Step 3. Keep The Innovation Flowing

To uncover ideas that will create innovation, shift your thinking from asking, “What do we need next?” to, “What are the needs of our customers?” Of course, the best way to answer that question is to spend time with them. An acronym we use to remind everyone about the importance of the voice-of-customer is NIHITO — “Nothing important happens in the office.”

Get out of your day-to-day grind and spend time assessing and discussing other areas of your business and the industry in the field with your customers. This doesn’t mean making more sales calls. These trips should be focused on your customers and the issues they are facing. Your product or service should be secondary in these conversations.

For example, you might be meeting with a local landscape contractor association and you’re asking open-ended questions about the challenges they are facing. They express frustration with the amount of time invested in making multiple trips to and from the jobsite to gather the various different materials needed to complete the project. This challenge could be met by your team with various solutions to package and deliver products in containers with the right quantity and type to meet this need. If the solution creates the right amount of value and fits within the realm of your team’s capabilities it could spark an innovative new service that is a win-win for you and your customers.

Asking open-ended questions enables your customers to talk about challenges in their business — even ones outside of your field of expertise. This process helps them peel back each layer of an onion until their core challenges are revealed — and that’s where opportunities are, where your next big breakthrough might come from. Over time, as you do this type of exercise, you’ll begin to see patterns and common threads of issues that start to rise to the surface.

Step 4. Filtering ideas

A challenge you’re likely to face when switching to an innovative culture is coming up with too many ideas. When you invite your team to bring you new ideas and spend time talking with others in the field, they will likely uncover dozens of challenges that should be addressed. For a lot of organizations, this is where innovation ends. They either try to implement all of them or find themselves unable to choose the best ideas to pursue.

To push past this stage of innovation, filter them and make sure they pass the PUP test.

P — Pervasively found

U — Urgently needed

P — Pay to solve

You are searching for the ideas that address real needs that likely weren’t offered up by customers within the first five minutes of a conversation — ideas that will address a need now and that people will gladly pay for. Those are the breakthroughs worth exploring. It’s also how you make sure your team isn’t pursuing too many solutions all at once or standing still under the weight of all the great ideas uncovered.

Vermeer has been in the composting market with grinders since the 1990s, but through our voice-of-customer work, we discovered there were other areas of composting operations that were being underserved. So, we looked for ways to meet those needs. In 2007, we partnered with Wildcat Mfg. Co., a company that made quality trommel screens and compost turners to extend our equipment offerings and alleviate the dependable service challenge customers told us they were experiencing. Vermeer acquired Wildcat in 2009 to better meet the industry’s needs through additional product innovation.

Sometimes huge breakthroughs take time to develop, whether due to regulations, technology or economics. Stay the course and continue to seek ways to make it happen. Consider protecting your ideas through a patent and/or seek out partners to help transform the idea into an innovative product or service.

Innovation doesn’t happen in a day or just inside a conference room. It takes a long-term commitment that requires a lot of legwork and the support of the entire organization, and in some cases an industry.

Ted Dirkx is an applications specialist for Recycling and Forestry at Vermeer Corporation. After studying composting and graduating with a degree in environmental studies from Central College, he joined equipment manufacturer Vermeer Corporation in Pella, Iowa. Traveling about 30 weeks a year, he has been roaming North America and beyond, helping organizations set up composting facilities, manufacture mulch, clear land and produce biofuels.