Top: Food waste slurry in 50,000 gallon tank prior to anaerobic digestion.

Nora Goldstein

In 2012, the Pennsylvania Department of Environmental Protection (PADEP) created General Permit WMGM042 Anaerobic Digester, which “authorizes the anaerobic digestion of animal manure on a farm mixed with (i) grease trap waste (collected from restaurants or grocery stores) and (ii) preconsumer and postconsumer food waste from commercial or institutional establishments, hereinafter referred as a ‘waste,’ and the beneficial use of the:

- Methane gas produced by the anaerobic digestion as fuel, including in the production of electricity;

- Waste solids removed from the digester as animal bedding material at the farm; and

- Liquid waste and solids removed from the digester as a soil additive for agricultural purposes.”

An early recipient of the WMGM042 permit is Reinford Farms, an 800-head dairy farm in Mifflintown (PA). Reinford Farms installed an anaerobic digester in 2008. Not long after the digester became operational, the farm began receiving inquiries about accepting loads of commercial food waste. It began taking food waste, mostly from grocery stores in the region. It was preprocessed using a forage chopper and added to the digester.

Over the years, the Reinfords saw an increase in the amount of contamination in the food waste streams that was building up in the digester and the storage lagoon. “We made a decision to clean up the food waste we were getting,” explains Brett Reinford. “We started looking at depackaging equipment in 2015, and purchased a Scott Equipment Turbo Separator in 2017.” The depackager is housed in a 5,600 sq. ft. warehouse, which serves as a food waste receiving and storage facility.

(1) Scott Equipment Turbo Separator depackager at Reinford Farms. (2) Slurry exiting depackager. (3) The one-eighth-inch screen mesh inside the secondary screen prior to discharge into the food waste tank. Photos courtesy of Reinford Farms

A few months after the Turbo Separator was installed, Reinford reached out to PADEP about bringing slurried food waste from its farm to other digesters. Staff from PADEP visited the farm to learn more about the depackager — and ended up deciding to impose restrictions on its operation, primarily to address contamination that may end up in the slurried food waste. While the actual amount of contamination is miniscule compared to the total quantity of food waste run through the Turbo Separator, tiny specks of plastic were visible in the farm fields, noted Reinford in an October 2020 BioCycle article. “That was the reason for DEP’s concern — and us quite frankly,” he adds.

Amended Permit With Depackaging Conditions

In the beginning of 2020, PADEP imposed limits on the amount of packaged food waste Reinford Farms could process while it developed regulatory language to address its contamination concerns. After reviewing and commenting on a number of drafts of the new permit language, Reinford Farms was issued an amended WMGM042 permit in early April 2021.

In the introductory description to what the permit allows, PADEP added the following: “The utilization of a depackaging unit(s) to mechanically separate preconsumer and postconsumer food waste from commercial establishments, institutional establishments, or industrial food manufacturing operations, from its packaging, prior to anaerobic digestion.”

Section D. of the permit imposes “Additional Operating Conditions for Farms Authorized to Use a Depackaging Unit Prior to Anaerobic Digestion.” These conditions are:

- “The depackaging unit(s) must be operated in a manner that prevents the shredding or fragmenting of packaging into small pieces that can progress through the operation in digester influent, digester effluent, and ultimately into the final beneficial use material.

- “The depackaging unit(s) must be operated within a fully enclosed facility.

- “No visible plastic fragments shall be in the digester effluent destined for land application, dewatered solids destined for land application, or for use as an animal bedding, and there shall be no visible plastics in the areas where the effluent or dewatered solids are ultimately land applied.

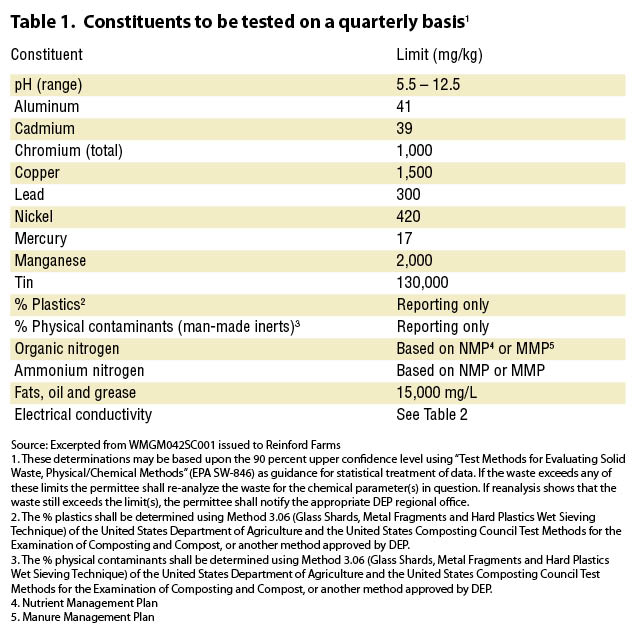

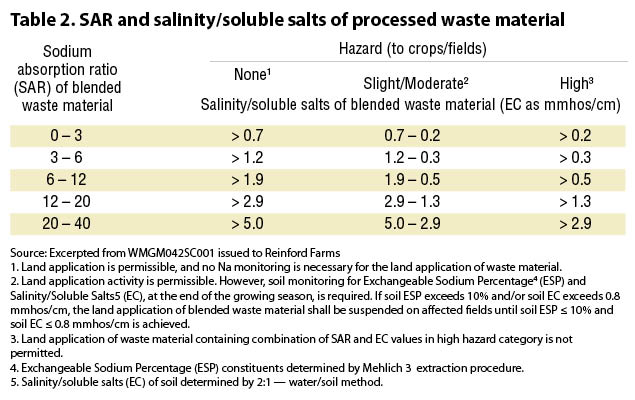

- “The permittee shall collect representative samples of the liquid and solid waste destined for beneficial use on a quarterly basis and analyze it for the constituents in Tables 1 and 2. Sampling events must be separated by at least 80 calendar days but not more than 100 calendar days. ……. The liquid and solid waste may be beneficially used by land application to agricultural lands as a soil additive if limits in Table 1 are satisfied, and the waste is shown that the electrical conductivity (EC) value for the sodium absorption ratio (SAR) of the processed material is below the high hazard category set forth in Table 2. The analysis for Table 1 shall be based upon “total” dry weight values, and conducted utilizing the “Test Methods for Evaluating Solid Waste, Physical/Chemical Methods” (EPA SW-846), or other methods approved by PADEP.”

The limits in Table 1 for “% Plastics” and “% Physical Contaminants (man-made inerts)” is “Reporting Only,” i.e., the PADEP does not set a specified limit. BioCycle corresponded with Chris Solloway, Environmental Group Manager, with PADEP’s Bureau of Waste Management about a definition of the term, Reporting Only. “Reinford Farms would use Method 3.06 from the United States Department of Agriculture and the United States Composting Council Test Methods for the Examination of Composting and Compost to determine the percentage of plastics (and other man-made inerts) that may be in the beneficial use material,” explains Solloway. “Reinford Farms would then report the results of those determinations. Neither plastics nor physical contaminates/inerts provide any beneficial contribution to the solids and liquids that are authorized for beneficial use. Therefore, plastics or physical contaminates/inerts cannot be a component of the solids or liquids that are beneficially used.”

The limits in Table 1 for “% Plastics” and “% Physical Contaminants (man-made inerts)” is “Reporting Only,” i.e., the PADEP does not set a specified limit. BioCycle corresponded with Chris Solloway, Environmental Group Manager, with PADEP’s Bureau of Waste Management about a definition of the term, Reporting Only. “Reinford Farms would use Method 3.06 from the United States Department of Agriculture and the United States Composting Council Test Methods for the Examination of Composting and Compost to determine the percentage of plastics (and other man-made inerts) that may be in the beneficial use material,” explains Solloway. “Reinford Farms would then report the results of those determinations. Neither plastics nor physical contaminates/inerts provide any beneficial contribution to the solids and liquids that are authorized for beneficial use. Therefore, plastics or physical contaminates/inerts cannot be a component of the solids or liquids that are beneficially used.”

Solids from manure presses equipped with a 1 millimeter screen. No visible contaminants are evident. This is the point where contaminants would be seen if they were not captured by the depackager and the secondary screen.

In contrast, PADEP’s General Permit WMGR025, which regulates composting facilities, has the following language: “Finished compost shall contain no more than 1% of synthetic (i.e. man-made) inert material, and no more than 0.5% of plastic material, as measured using a 4 millimeter sieve.” It is unclear why the Department did not use these existing limits in the WMGR025 permit in Table 1 in the amended WMGR042 farm digester permit.

The limits in Table 2 regarding salinity were created because of the salt content in food. “With the ability to depackage food waste, it is possible that a permittee could receive and process large volumes of food waste material that could affect the sodium absorption ratio or electrical conductivity of the liquid material destined for beneficial use,” says Solloway. “The results of the combination of sodium absorption ratio and electrical conductivity values provide insight into whether the liquid is suitable for agricultural purposes.”

The limits in Table 2 regarding salinity were created because of the salt content in food. “With the ability to depackage food waste, it is possible that a permittee could receive and process large volumes of food waste material that could affect the sodium absorption ratio or electrical conductivity of the liquid material destined for beneficial use,” says Solloway. “The results of the combination of sodium absorption ratio and electrical conductivity values provide insight into whether the liquid is suitable for agricultural purposes.”

BioCycle queried a number of states where anaerobic digestion and/or composting facilities are utilizing depackaging equipment to preprocess food waste. Some states did not have specific regulatory language regarding depackagers; others require a solid waste processing facility permit be obtained. In terms of contamination limits, the states queried utilize existing physical contamination limits, e.g, what exists for compost products.

Reinford appreciates PADEP’s attempt at regulating the level of contaminants in the digestate, but notes that the limits need to be achievable. The farm has taken numerous steps to eliminate contamination before the slurried food waste is blended with manure and pumped into the digester, including adjustments to machine speed, and the screen sizes. “We use a three-eighth-inch screen on the discharge from the depackager, and a one-eighth-inch screen in our secondary screen before the slurry goes to the food waste tank,” explains Reinford. “After digestion, our manure press filters through a 1 mm screen. At that point, we can evaluate how well we are doing with contaminant removal and inspect the manure solids for plastics. There is very little.”

Currently, WMGM042 Anaerobic Digester is the only PADEP general permit that authorizes the utilization of a depackaging unit to process food waste material. Food waste depackaging equipment is in use elsewhere in the Commonwealth of Pennsylvania, including at a Divert facility in Mechanicsburg and the Hermitage Municipal Authority in Hermitage. “It is extremely likely that a new general permit for commercial depackaging operations will be created,” adds Solloway. “Further, discussions between the Waste and Water Programs regarding the permitting of food waste management at wastewater treatment plants, which can also include depackaging activities, have already been held and will continue until an adequate permitting pathway for these operations is determined.”