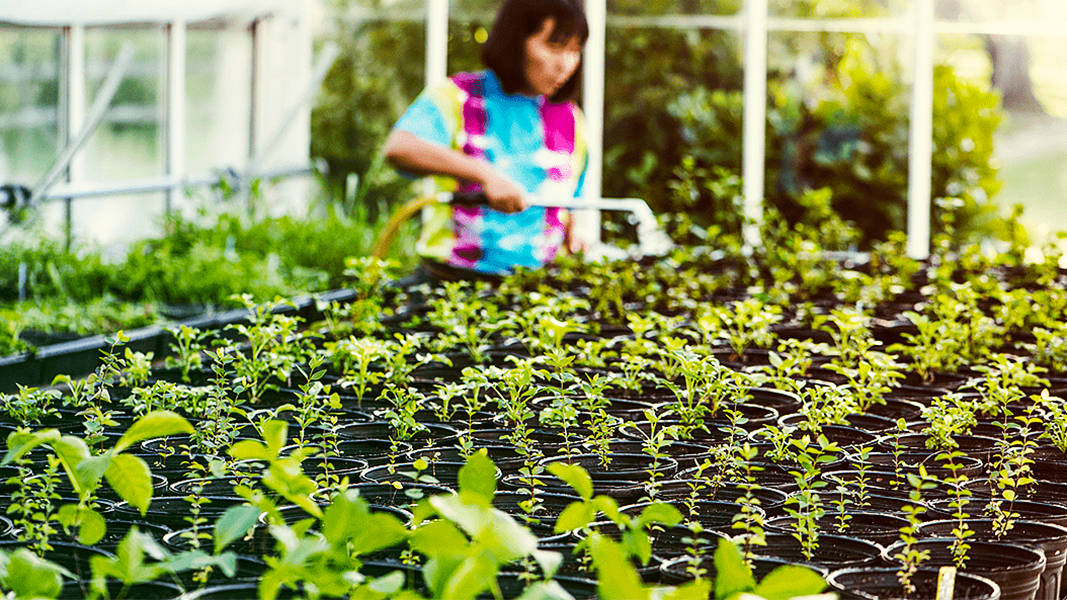

Top: Compost made at GreenAcres is a component of its vegetable and flower start media mixes in the greenhouse. Photo courtesy Green Mountain Technologies

The GreenAcres Foundation in the Cincinnati, Ohio area is a multifaceted community nonprofit organization focused on regenerative organic farming and community education. For more than 30 years, it has been investing in programs including grass-fed beef and poultry, no-till organic vegetable production and equine programs. Composting has long been an integral aspect of GreenAcres’ regenerative agriculture practices, in particular as vegetable production was transitioned to no-till organic. Feedstocks for the composting operation have been a mix of horse manure and bedding along with chicken litter and crop residuals from the farm and food waste from staff and educational event programs. In January 2021, GreenAcres converted its composting process from a turned windrow to a Green Mountain Technologies’ Site Built Earth Flow automated in-vessel system equipped with an auger mixer, active aeration built into the floor, and a greenhouse roof.

The compost manager, Nate Bundy, was seeking a faster and more efficient way to increase compost volume to expand the organic no-till farming operations. The turned windrow process required 10 to 20 hours per week of equipment and labor time to turn the materials weekly over a period of four-plus months. Conversely, the in-vessel system mixes and aerates over a two-week period before material is unloaded with a skid-steer and cured for four to six weeks prior to application on crop fields. GreenAcres processes about 70 cubic yards/month of manure and bedding produced by its 21 horses, along with the other feedstocks. “While the system is expensive at the onset, the long-term investment has a return on both labor and costs,” explains Bundy. “Labor has been more immediately affected. I am no longer spending 16 hours a week in a skid steer and have the opportunity to spend more time in the field and greenhouse with our apprentices. We are also producing more compost than our turned windrow process, which helps us more quickly transition into no-till.”

Finished compost is used on about 5 acres of food production and in many educational perennial gardens on the property. “The compost is also a huge component of our vegetable and flower start media mixes in the greenhouse,” adds Bundy, noting that GreenAcres produces over 50 different types of vegetables and flowers in the field. “Our mission relies heavily on education. We serve close to 30,000 visitors a year which includes both students and adults. The majority are school-aged students. Every fieldtrip that has a lunch gets a whole lesson on composting and so every fieldtrip in a way gets insight into our facility.”

With the increased production of compost, the farm has been able to transition completely to no-till. “We do this through heavy compost mulch applications,” he says. “These applications help suppress weeds, improve soil physical structure, and provide lots of organic matter to our soil. This is the first year into the transition to all no-till and we are seeing a great improvement in overall yield, a decrease in weeds, and less issues with diseases.”