Understanding what you’re sampling for at composting and anaerobic digestion facilities dictates sampling procedures.

Craig Coker

BioCycle November 2016

Taking samples for analysis is a key function in managing an organics recycling facility. Samples of feedstocks are needed to understand important parameters in composting and anaerobic digestion, such as carbon:nitrogen ratios, putrescibility, bulk density, methane gas generation potential, toxicity to the anaerobic bacteria, and others. Samples of biogas are needed to understand energy and contaminant contents. Samples of products are needed to verify compliance with regulatory parameters and with market interests.

This multitude of needs is why every organics recycling facility should have a sampling plan, which spells out the basics of sampling: Who? Why? What? Where? How? In other words, it should explain who is doing the sampling, what is being sampled, where they are sampling (both in location at the facility and in relation to the process flow), why are they sampling (regulatory compliance, market interests, other), and how they are doing it. It should also include sampling frequency and how much of a sample is to be taken. For example, the plan may spell out that compost product metals analysis samples be made up (or composited) of weekly representative grab samples and submitted monthly, where samples for fecal coliform contamination would be representative samples taken once per month.

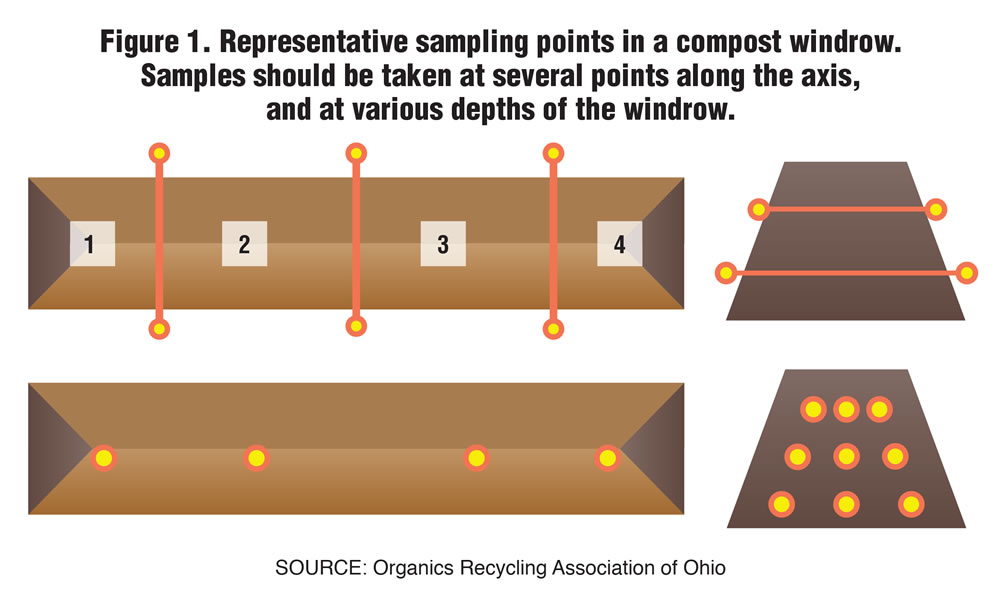

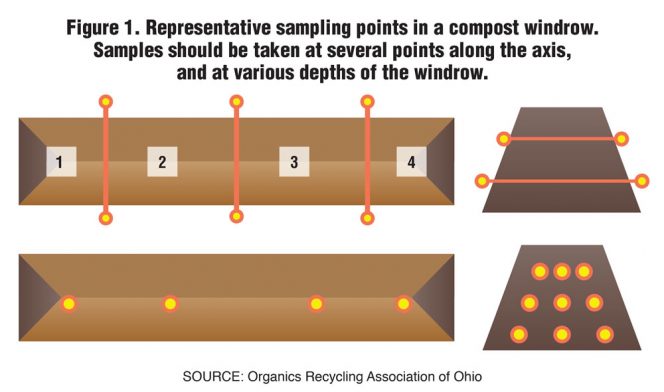

Figure 1. Representative sampling points in a compost windrow.

Samples should be taken at several points along the axis, and at various depths of the windrow. SOURCE: Organics Recycling Association of Ohio

Understanding what is being sampled is important to making sure the proper collection equipment and procedures are being used. Clearly, the equipment needed to sample compost for finished product quality is different from the equipment needed to sample a storm water discharge to meet discharge permit monitoring requirements.

The “where” relates to taking a sample from the right point in the manufacturing process flow in order to be confident that the right information will be obtained. For example, taking a pathogen sample in a composting facility before the windrows or piles reach the correct temperature for the needed duration will result in much different, and less useful, information than sampling the finished compost product storage pile. Where to sample also influences the type of sampling gear used. Sampling outdoors requires different personal protective equipment (PPE) than sampling in a confined space like a storm drain, where more protective PPE will likely be needed. The sampling plan should state where each sample, or subsample, is to be taken.

How To Sample

Lastly, there is the how. The two ways to sample any environmental medium are a grab sample, and a composite sample. Grab samples are, as the name implies, just a quick “grab” of a portion of the material to be analyzed. Composite samples are taken in small “mini-samples,” either on a spatial basis (like temperature measurements in a windrow), temporal basis (time-composited samples) or on a production basis (flow-composited samples). Most of the sampling done in organics recycling facilities for laboratory analysis is done using grab samples. Composited samples are usually done in water quality and air emissions monitoring.

The term “grab sample” can be misleading. Even though a grab sample is being taken, in many cases it should be “representative” of the material being analyzed. Whether it is a true discrete grab sample or a representative grab sample also depends on what is being analyzed. For example, a discrete grab sample is important when variability needs to be understood (like moisture content or free air space of compost in a windrow). Representative samples are needed where trying to understand system-wide process and product quality goals (like metals content in finished compost or volatile fatty acids in a digester feedstock).

Representation in grab sampling means taking a series of subsamples from various places in the materials being analyzed. If the material is flowable and moving through the facility, subsampling is very similar to the composite sampling method used for air or water sampling, as subsamples will be taken at certain time increments or after certain volume or mass amounts have passed the sampling point. For example, if an operator is interested in hydrogen sulfide content of a biogas, the gas could be sampled every several hours or after a certain volume had passed into the storage bladder. It is still a grab sample, but the sample is made up the several subsamples that represent an average condition. Even though a representative sample is being compiled, by sampling on different days, the operator will also be able to understand daily variability in biogas characteristics.

Representative grab sampling in compost piles requires subsampling in various areas of the pile and windrow, both along its length and into its depth. The procedure is to take a subsample of 1 to 2 cups worth from each sampling point, mix the subsamples together in a bucket, then fill a plastic bag with scoopfuls of the mixed material in the bucket.

The size of the sample taken depends on the type of analyses being done, how heterogeneous the material is, and how much variability is expected in the material being sampled. Generally, for dry materials like composts and soils, a 1-gallon sealable plastic bag is enough (most laboratories ask for two 1-gallon bags if doing compost maturity tests using germination). For water samples, a 1-liter plastic bottle is usually sufficient. For gas samples, a one-liter Tedlar bag is normally used. Often with water or gas samples, a second sample container is filled and sent to the lab for analysis duplication purposes.

The accompanying sidebars describe procedures for storm water discharge sampling and biogas sampling.

Sample containers should be labeled with the date and time of sampling, source and location of sampling, name of the sampler, identification number for the sample, indication of sample preservation method, and a completed chain-of-custody form. Many laboratories offer complete sampling kits, with containers, preservatives as needed, and shipping containers and labels.

The sampling plan should also detail how samples should be packed and shipped to the laboratory. If a sample is to be analyzed for biological parameters (such as fecal coliform, Salmonella sp. bacteria, fungi, etc.), then the sample containers should be refrigerated and shipped in a Styrofoam container. To minimize the potential for bacterial growth, volatilization or biodegradation between sampling and analysis, keep the sample as cool as possible without freezing. Preferably, pack samples in crushed or cubed ice, or a commercial ice substitute before shipment. Avoid using dry ice because it may freeze the samples and cause the containers to break. Dry ice may also affect the pH of the samples.

Sampling and analysis is critical to good process management in both composting and anaerobic digestion. Developing a sound sampling plan is an important component of professional facility management.

Craig Coker is a Senior Editor at BioCycle and CEO of the firm Coker Composting & Consulting (www.cokercompost.com), near Roanoke VA. He can be reached at cscoker@jgpress.com.