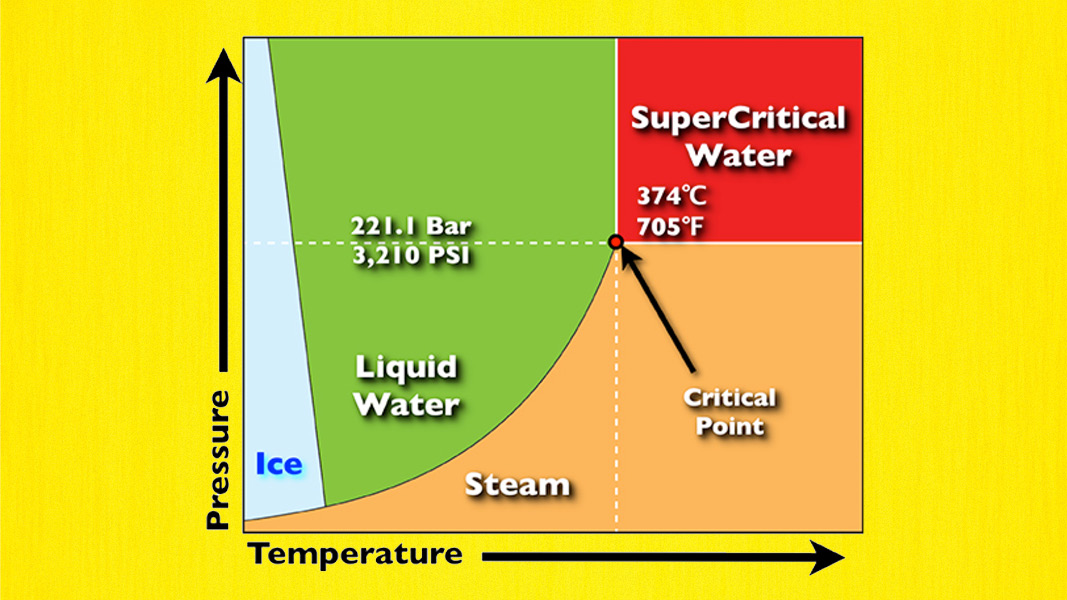

Top: SCWO reactions occur above the critical point of water. Graphic by Jonathan Kamler

Nora Goldstein

The Orange County Sanitation District (OC San) of Fountain Valley, CA serves a population of 2.6 million people in central and northwest Orange County and processes more than 180 million gallons/day of wastewater. Solids are processed in anaerobic digesters; conditioned biogas is used for electricity and heat at the treatment plant. Most of OC San’s biosolids are either composted to create a soil amendment or directly applied to agricultural land.

In accordance with the principles of its biosolids management policy, OC San maintains a diverse portfolio of biosolids management options that utilize multiple contractors, facilities, and product markets while maintaining fail-safe, back-up options. Part of its backup options plan includes evaluating new and innovative technologies. One new solids treatment that has been under review for several years is supercritical water oxidation (SCWO), which harnesses the unique properties of water above its thermodynamic critical point (374°C, 221 bar) to convert complex compounds such as PFAS (per- and polyfluoroalkyl substances) to element compounds like nitrogen, water, carbon dioxide, and mineral salts in a single step. Organic compounds, usually insoluble in liquid water, are highly soluble in supercritical water, according to a U.S. EPA research brief about SCWO. In the presence of an oxidizing agent (such as oxygen), supercritical water dissolves and oxidizes various hazardous organic pollutants.

One company that is commercializing a SCWO system is 374Water in Durham, North Carolina. Its AirSCWO™ process uses the power of supercritical water and the energy in wet waste streams to fully mineralize waste in a single and rapid step. “All of the organic fraction of the waste (~97% for biosolids) is being oxidized and converted to water, carbon dioxide, and energy,” explains Kobe Nagar, CEO of 374Water. “Some of the energy is used to heat up the feedstock and the air (which is used as the oxidant). The remainder of the energy can be converted to electricity and offset auxiliary system loads.” The company is scaling the technology from a 1 metric ton/day pilot system used at Duke University to three commercial systems with the following capacities: 6 metric tons/day, 30 metric tons/day, and 200 metric tons/day.

OC San and 374Water have entered into an agreement to perform a validation of the technology for OCSan’s wet waste streams. A 6 metric tons/day AirSCWO unit will be installed that can process different forms of wastewater residuals and biosolids. The project at OC San will focus on treating primary and concentrated thickened sludge (CTS), biosolids, and untreated food waste slurries. Important characteristics of the feedstocks are caloric content, pumpability, and small particle sizes. “OC San wants to see how well the AirSCWO technology addresses predigested sludge,” says Rob Thompson, Deputy General Manager of OC San. “The sludges (~3-7% total solids) will first be fed to a dewatering unit, which will screen out undesirable materials, equalize the two feed streams, and dewater the equalized stream to 12 to 15% total solids. The resulting stream will be fed to the AirSCWO system where the streams will be treated via supercritical water oxidation resulting in air emissions, water, and inorganic solids.”

Food waste can be introduced to the dewatering unit through an auxiliary input. It would be mixed with the primary sludge and CTS, dewatered, and fed to the system. “Overall, the system will reduce volatile solids and chemical oxygen demand by >99% and >93% of ammonia and other forms of nitrogen-to-nitrogen gas,” says Nagar. “Although AirSCWO is not designed specifically for nitrogen elimination, the effluent produced is significantly lower in nitrogen than digestion.”

Part of the project will be used to document the ability of the system to destroy plastics, PFAS compounds, and other constituents of emerging concern that can be concentrated in sludge streams. The intense energy in supercritical water coupled with the addition of excess oxygen causes the chemical bonds of these complex organic molecules to break and release an enormous amount of energy. In the case of PFAS, the byproducts are carbon dioxide, water, inorganic fluoride ions, and inorganic fluoride precipitates (e.g., calcium fluoride).

The system will be installed at OC San’s Fountain Valley, CA wastewater plant in 2023. The AirSCWO unit will be housed in a 40-foot cargo container and the dewatering unit will be in a second 40-foot cargo container. (Holding tanks will be outside the containers.) It will operate in parallel with the current wastewater treatment system processing up to six wet metric tons/day of sludge. “OC San hopes to benefit from this project by fully testing and understanding the ability of the technology to destroy emerging contaminants and to validate the operations and maintenance costs, opportunities, and limitations of this new technology,” notes Thompson. “It has the potential to solve several challenges facing OC San, including solids processing and transportation costs, air emissions requirements for methane and power generation equipment, emerging contaminants such as PFAS compounds and microplastics, food waste utilization, and efficient use of OC San’s treatment plant properties.”

The cost of the system ranges from $25 to $150/wet metric ton depending on the size of the unit and whether the recovered resources (water, energy, minerals) can be monetized, adds Nagar. “With the larger units, monetization of the recovered resources could convert cost to income.”