For compostable plastics to be allowed as an input for organic agriculture, a petition must be filed with the National Organic Standards Board. The ideal petition would identify specific types of compostable plastics so that the allowance will not be limited to only one.

Lindsay Fernandez-Salvador

BioCycle August 2012, Vol. 53, No. 8, p. 45

Making good compost is similar to making healthy organic crops: It depends on the inputs! Just as there are standards for what goes into organic crop production (inputs), there are standards for what goes into a compost as feedstock. Compost is an excellent example of an input regularly used in organic production. But what happens when members of the organic industry and the composting industry disagree on appropriate feedstocks? How do we embrace waste reduction and new technologies, while preserving the organic principle to exercise caution before allowing new inputs?

Compostable plastics are on most composters radar screen these days, especially those who make compost for organic production. According to the National Organic Program (NOP), compostable plastics are currently not allowed as feedstocks for compost used in organic production. “We agree that this is a new development in handling food waste, but…these represent synthetic materials and would need review…by the NOSB [National Organic Standards Board],” USDA Deputy Administrator of the NOP Miles McEvoy wrote in a May 6, 2011 policy clarification letter to stakeholders. In order for compostable plastics to be evaluated as a feedstock in compost for organic production, these materials must be petitioned for addition to the National List (7 CFR Part 205.601) and reviewed by the NOSB.

Leaders in both the organic and composting industries recognize that compostable plastics are here to stay. Therefore a solution that meets the needs of both industries must be found.

Standards For Inputs

The organic standards for crop inputs are generally divided along a clear line — natural or synthetic. If a substance is natural, it is allowed as an input, with a few exceptions. Natural materials include food waste and yard trimmings, crop residues, mined gypsum, manure and microbial inoculants. If a substance is synthetic, it is not allowed as an input, also with a few specific exceptions. Some of the synthetic materials allowed as compost feedstocks include recycled paper, as long as it is free from glossy or colored inks, and certain micronutrients. All synthetic materials used as inputs in organic production must be listed on the National List, which includes Title 7 CFR Part 205, Sections 205.601, 205.603, and 205.605(b). Allowed synthetic compost feedstocks are listed in 205.601(c).

It is clear which synthetic materials are allowed because they appear on the National List; however, determining if something is natural or synthetic is more difficult. The organic standards define synthetic as “formulated or manufactured by a chemical process or by a process that chemically changes a substance extracted from naturally occurring plant, animal, or mineral sources, except that such term shall not apply to substances created by naturally occurring biological processes” (205.2 Terms Defined). This definition actually defines synthetic materials in two ways — those created by a chemical process and those that are chemically changed by their extraction process.

A classic example of a material created by a synthetic process would be urea, where ammonia and carbon dioxide chemically react to form the synthetic nitrogen source commonly used in conventional agriculture. Similarly, extraction by physical or chemical means may also create a synthetic material. For example, wood vinegar is extracted by burning wood in an airless environment and condensing the smoke into liquid factions. The wood vinegar, although physically extracted, is chemically altered by the extraction process and thus is synthetic.

Compostable plastics are also examples of synthetic materials. Examining the manufacturing process for polylactic acid (PLA), a common compostable plastic, there are several steps that would create a synthetic material. PLA manufacturing starts with lactic acid, a natural material that undergoes depolymerization to form different lactide forms (LL, DD, Meso). These lactides then undergo “ring opening polymerization” to produce a family of biodegradable polymers, including PLA, thus producing a chemical change (Vink et al, 2003) .

Manufacturing processes for other forms of compostable plastics also clearly render the products synthetic. To be fully compliant with the organic regulations, compostable plastics must therefore be petitioned for addition to the National List as allowed synthetic feedstocks.

National List Petition Process

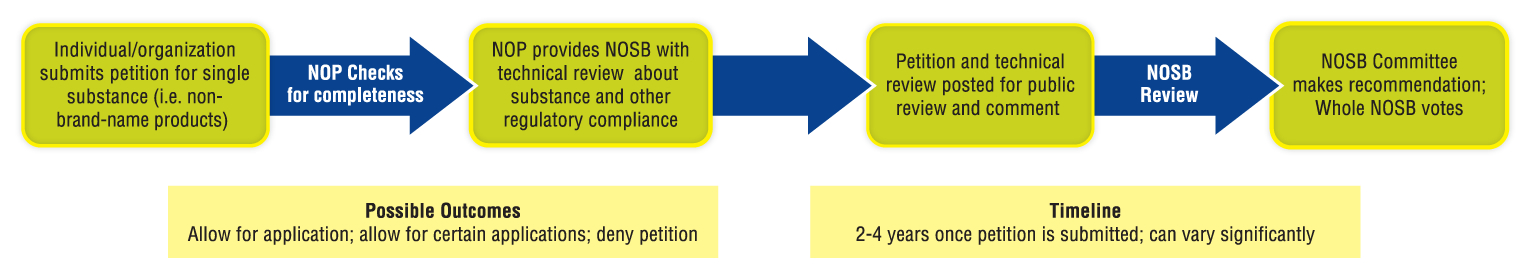

The National List petition process is a multistep, public regulatory process that involves the petitioner, the NOP, the NOSB and the public. The petitioner could be any individual or organization who submits a petition to add, remove or amend the listing of any substance. The NOSB is a Federal Advisory Committee that reviews the petition based on specific criteria in the Organic Foods Production Act (OFPA) of 1990. The NOP accepts petitions, solicits public comments and manages all communication with petitioners (National Organic Program, 2012). Figure 1 provides a graphic explanation of the petition process.All petitions require some key information that helps the NOSB and the public to determine whether they support the petition, or whether any restrictions must be placed on the substance. This information is derived from criteria contained in OFPA Section 2119(m), which requires the NOSB to evaluate:

1) Potential of the substance for detrimental chemical interactions with other materials used in organic farming systems;

2) Toxicity and mode of action of the substance and of its breakdown products or any contaminants, and the persistence and areas of concentration in the environment;

3) Probability of environmental contamination during manufacture, use, misuse or disposal of such substance;

4) Effect of the substance on human health;

5) Effects of the substance on biological and chemical interactions in the agroecosystem, including the physiological effects of the substance on soil organisms (including the salt index and solubility of the soil), crops and livestock;

6) Alternatives to using the substance in terms of practices or other available materials; and

7) Compatibility with a system of sustainable agriculture.

Information contained in the petition to address these criteria must include a detailed description of the manufacturing process from the source of the material to the final substance, the chemical properties of the substance, including its effect on human and environmental health, and any regulatory relevance, such as rulings by the Food and Drug Administration, US EPA or other government agencies.

Compostable Plastics Petition

To date, no petition for compostable plastics has been filed with the NOSB. Although the petition process seems straightforward at the outset, the petition for compostable plastics will be considerably more complex for various reasons. These materials are made using relatively new technology, and advances are being made at a rapid pace. At the same time, there is a lack of significant research on the environmental and human health effects of the manufacture and disposal of such products. Thus, a petition for compostable plastics must be as thorough as possible to ensure that the outcome works for both the organic and composting industries.

The ideal petition would identify specific types of compostable plastics so that if added to the National List, the allowance will not be limited to only one type. Some of the common compostable plastics include polylactic acid (PLA), poly-3-hydroxybutyrate (PHB), and starch-based plastics. These all have different sources, manufacturing processes, chemical properties and effects on environmental and human health. After identifying the types of compostable plastics, the petition must suggest how to identify compliant compostable plastics, such as requiring that they be manufactured to American Society for Testing and Materials (ASTM) specifications, or be certified as compostable by the Biodegradable Products Institute (BPI).

The petitioner should realize that these two identification methods may increase the burden on composters to ensure that all incoming compostable plastic feedstocks are appropriately verified; this may be alleviated by requiring that any compliant compostable plastic have a visual “flag” (such as a green stripe or certification logo) so composters can differentiate between compostables and noncompostables while sorting feedstocks in their facility. The easiest identification method is that any product claiming compostability be allowed. This approach, however, will be the most difficult to justify for adding these materials to the National List.

The Organic Material Review Institute’s (OMRI) role with regard to compostable plastics has been to offer OMRI’s knowledge about the petition process, how enforcement comes into play, and highlight the ideal situation OMRI would look for should compostable plastics get onto the National List. As both the organic and composting industries grow, they continue to aspire to the same principle — to contribute to the sustainability of the soil, planet and health. This common goal should be used as the focal point of the approaching debate on compostable plastics in organic production.

Lindsay Fernandez-Salvador is Program Director with the Organic Materials Review Institute, a national nonprofit that determines which input products are allowed for use in organic production and processing. OMRI is based in Eugene, Oregon (www.omri.org).

References

National Organic Program, USDA. (2012, 04 24). How to file a petition. Retrieved from http://www.ams.usda.gov/AMSv1.0/ams.fetchTemplateData.do?template=TemplateN&navID=HowtoFileaPetitionNOSBHome&rightNav1=HowtoFileaPetitionNOSBHome&topNav=&leftNav=NationalOrganicProgram&page=NOPFilingaPetition&resultType=&acct=nopgeninfo

Vink, E. T. H., Rabago, K. R., Glassner, D. A., & Gruber, P. R. (2003). Applications of life cycle assesment to Nature WorksTM polylactide (PLA) production. Polymer Degradation and Stability, 80, 403-419.