The air permitting process has many nuances that can be thoughtfully anticipated to avoid significant project costs and delays.

Part I

John Hinckley

BioCycle September 2017

Designing renewable energy projects such as anaerobic digesters with adequate air pollution control technologies to meet air quality permitting requirements originating from the Clean Air Act is on the list of must-do tasks for facility developers and operators. More stringent requirements are triggered if renewable energy projects such as anaerobic digesters and biomass-fueled boilers are proposed to be located in areas with already impaired air quality.

The guidance in this article is divided into six sections, which correspond to significant parts of the usual sequence of events in the air permitting process: Site evaluation; Emission estimation; Emission control evaluation; Air quality modeling; Permit application preparation; and Post permit compliance. Part I covers site evaluation and emission estimation. Part II, to appear in the next issue of BioCycle, covers the remainder.

Site Evaluation

Evaluating the site where the facility will be constructed is a critical first step to understanding how much effort is needed to permit an emission source. Addressing the following site related questions will help assess the permitting feasibility of the site being considered.

Figure 1. Significant Impact Area (SIA) to map interactive emission sources

GIS image by Jaknouse at English Wikipedia / CC BY

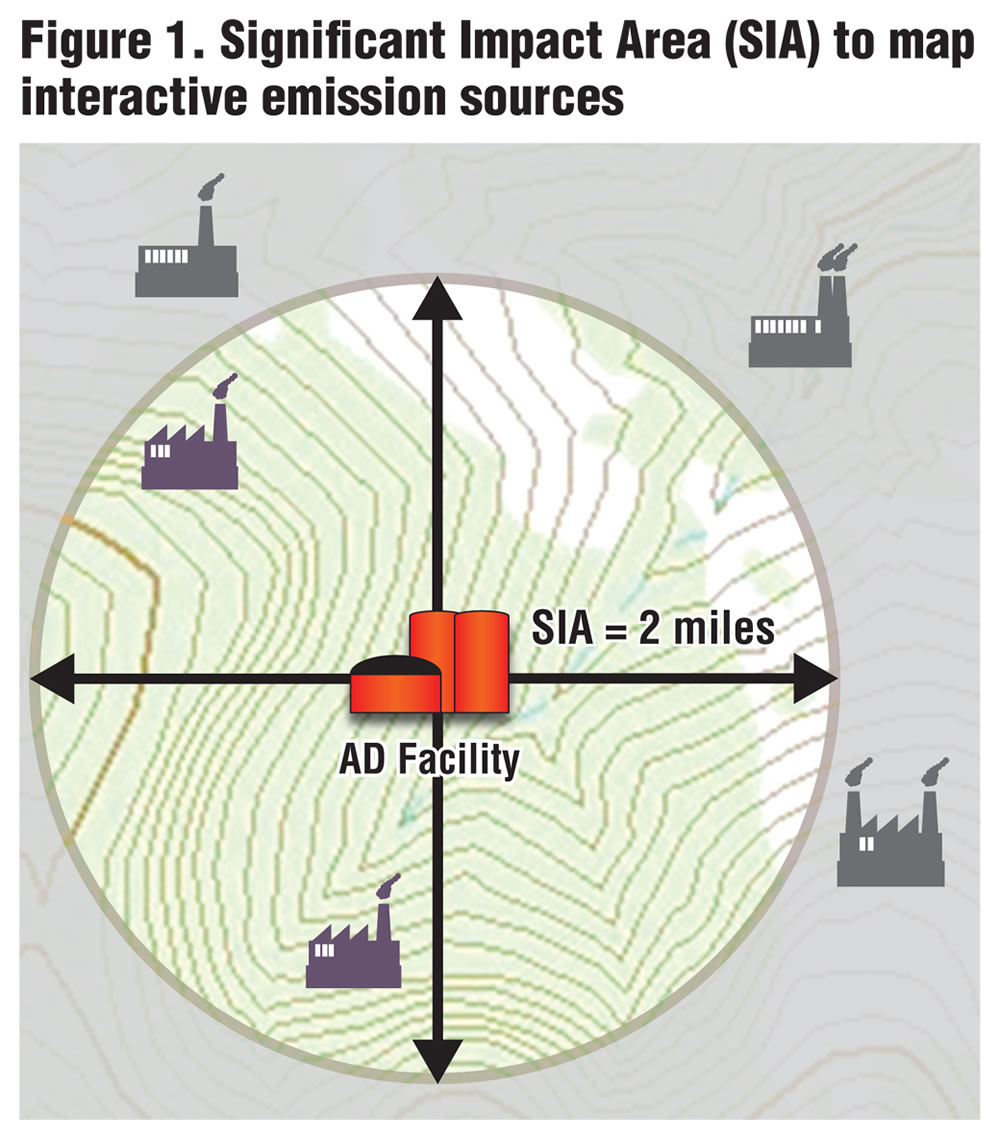

Other significant emission sources in the vicinity? In some cases, the air permit application for the proposed facility must reflect the emissions from existing facilities located close to the proposed site within what is called the Significant Impact Area (SIA). The SIA is used to determine whether other permitted existing emission sources near a proposed emission source should be included in an air quality modeling study for the proposed emission source. The SIA is essentially a circle centered on the proposed emission source, with a radius corresponding to the furthest distance to where air quality model-predicted concentrations meet or exceed the significance level for the pollutants modeled (Figure 1). Any emission sources located within the SIA may have to be included in the air quality modeling analysis, which can make it more challenging to demonstrate that air quality will not be overwhelmed by the project. It could also pose a problem after the facility is constructed if there are complaints, where it can be difficult to differentiate between the newly constructed project and the other existing facilities.

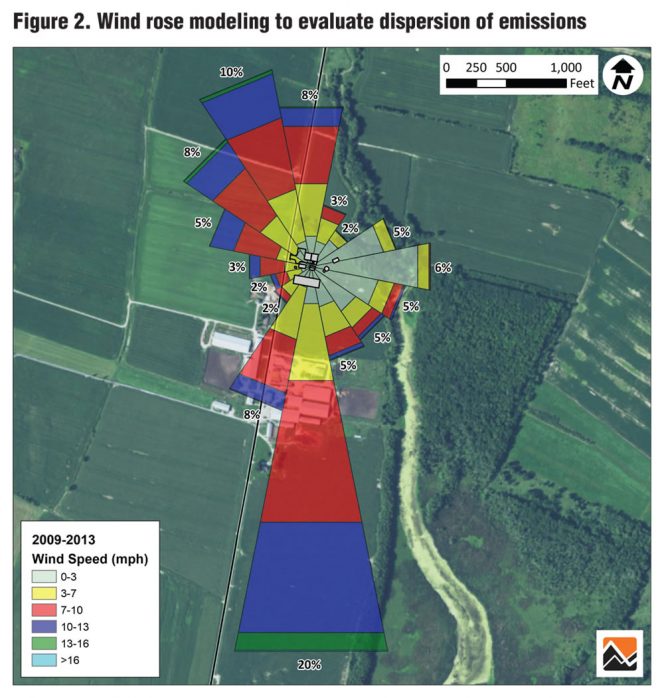

Prevailing winds? Understanding the prevailing winds identifies the direction(s) emissions will travel towards most of the time. Use of a wind rose — a graphical representation of the commonly occurring wind directions and wind speeds — is beneficial to understanding prevailing winds. It also provides the percent of time for each common wind direction and wind speed, including the percent of time when there is no wind. Wind roses are typically constructed with hourly wind speed and wind direction data collected at the closest airport to the proposed site.

A wind rose constructed to inform the design of a proposed anaerobic digester project (Figure 2) helped the developer understand that the dispersion of emissions from the generator stack was limited because the stack was too short and located upwind of a large building. The model illustrated that emissions would be trapped on the downwind side of the building, with better dispersion achieved by raising the stack height and/or moving the stack to the side of the building.

Distance to property boundary? Facilities sited close to their property boundary do not have ample distance to disperse plumes of emissions before crossing the facility’s property boundary (which is the usual location for regulatory compliance). This may result in more difficulty demonstrating compliance with pertinent air quality standards and opposition from neighboring property owners. With air permits, “ambient air” impacts are only evaluated outside the site property line, provided the property has a structure (such as a fence) that prevents public access to the site. The U.S. EPA defines ambient air as air that is readily accessible to the general public. A facility located near the property line may need to spend more money on advanced emission control and/or taller emission stacks to enable dispersion and dilution than one which is not.

Sensitive receptors nearby? Sensitive receptors are places where people who are sensitive to poor air quality live and work, e.g., schools, hospitals and retirement homes. A project located at or near one or more sensitive receptors may need to allocate more budget to emissions control and/or stack height than one which is not in order to minimize the risk of air quality impacts.

On-site and surrounding terrain? The topography, or “lay of the land,” can dramatically influence the feasibility of obtaining an air permit. For example, projects surrounded by very hilly to mountainous terrain may have difficulty demonstrating compliance with air quality standards. The terrain can limit dispersion of emissions by intercepting the plume of emissions from a stack, potentially resulting in violations of air quality standards. Facilities in this type of location also are candidates for more costly advanced emission control and/or taller emission stacks.

Building layout? Building locations and heights can affect emissions dispersion. Emissions can be trapped in the downwind side of a building due to a condition called

“building downwash,” which is essentially an area where air swirls close to the ground, thereby trapping emissions.

Emission Estimation

Estimating emissions is a critical, early step in the air permitting process to help determine what permitting requirements will be triggered by the level of emissions from a proposed facility. This step involves estimating the quantity of air pollutant emissions to the ambient air in terms of tons of each air pollutant per year (for example, 49 tons/year of nitrogen oxides, or NOx). The emission estimate is used to determine whether a proposed project will be a minor source or a major source. The accompanying glossary defines various terms used when estimating emissions.

It is important to make the distinction between minor and major sources early in the planning process, because major sources can require substantially more time and budget to permit. Equally significant is performing an emission estimate early in the planning process because emission control equipment and operating limits can be included in a proposed facility’s design to reduce the level of estimated emissions to qualify it as a minor source. Lastly, it can be used to eliminate the requirement to perform air quality modeling.

“Potential to emit” (PTE) is a permitting term often used during the emission estimate step of the permitting process. The PTE is the highest level of air pollutant emissions a facility can produce in a year. In the case of an AD facility, at the highest level, it could be thought of as the digester’s maximum throughput and all of the combustion sources (generator, boiler, flare, etc.) operating at maximum capacity for every hour of the year. However, the level can be reduced at least twice — first, to represent the reduction in operating time needed for routine maintenance for all equipment, and second, to represent any proposed reductions in operation time and emission control equipment to be covered by a legally enforceable air permit.

An emission estimate significantly factored into the design of an AD project that was permitted approximately one year ago. The initial emission estimate indicated air quality modeling would have to be performed for some of the electric generator’s pollutants. Armed with this information, the equipment vendor was able to offer a generator that was tuned somewhat differently to reduce those emissions below the modeling thresholds at no additional cost.

The emission estimate also revealed that formaldehyde (a hazardous air pollutant or HAP) emissions would be significant and would therefore have to be controlled with an oxidation catalyst, which would add to the project cost. Interestingly, the oxidation catalyst would also significantly reduce the future annual emission fee for the facility by reducing emissions of multiple pollutants. Fortunately, this information was developed early in the planning process, so the development team had adequate time to react and plan accordingly.

The emission estimate for an AD and composting facility in southern New Jersey clearly identified the need to reduce volatile organic compound (VOC) and nitrogen oxide (NOx) emissions. The initial PTE estimate showed uncontrolled VOC and NOx emissions exceeding the major source threshold, confirming the need to include catalysts in the project design to reduce the emissions of those pollutants below the major source level. The emission estimate also identified the need to reduce ammonia emissions. Ammonia is not a HAP, but is regulated as an air toxic in many states. Therefore, ammonia emission control was included in the design of this facility.

There are many sources of emissions data including manufacturer’s guaranteed not-to-exceed emission factors, site-specific emission factors, and AP-42 emission factors. The quality, and availability, of these factors should be considered when estimating emissions, per the following brief explanations:

Manufacturer’s Guarantee: Manufacturer’s “guaranteed not-to-exceed factors” are emission levels that the manufacturer offers because it has extensively tested the emissions. For example, a generator manufacturer may guarantee the NOx emissions will not exceed two grams per brake horsepower-hour (2 g/BHP). Air permitting agencies frequently accept emission estimates based upon these factors.

Site Data: Site-specific emissions data (stack test data) is emission data that was measured for a comparable existing facility and subsequently approved by an air permitting agency. Site-specific data is not always available, especially for anaerobic digesters. However, over time, it should become more available as more AD facilities are constructed and tested. This occurred in the biomass sector, where 15 years ago, very little site-specific information was available for small wood-fired boilers burning either wood chips or pellets. Today, numerous stack tests are available for these systems.

AP-42 Factors: EPA’s AP-42 emission factors can be used when manufacturer’s not-to-exceed emission factors or site-specific information is not available. These factors are available on EPA’s website and can be used for a wide variety of emission sources. However, the AP-42 does not cover all types of emission sources, including many anaerobic digesters. Further, the AP-42 is not updated annually, so many of the factors could represent emissions from much older, less efficient equipment. Therefore, using AP-42 can render a conservative (high) estimate of emissions, which can ultimately make the permitting process more challenging by triggering more permitting requirements.

John Hinckley, QEP is an air quality permitting expert and a Director with RSG in White River Junction, Vermont (John.HinckleyJr@rsginc.com).