BioCycle December 2012, Vol. 53, No. 12, p. 19

Cheyenne, Wyoming: Microsoft Data Center Project Powered By Biogas

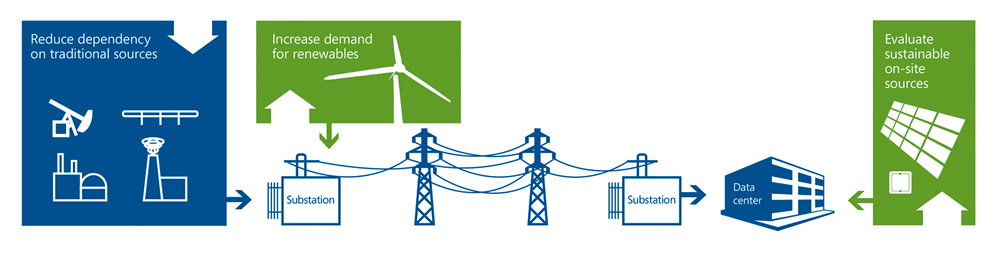

Microsoft moves ahead on environmentally-friendly on-site power generation with biogas powered data center.

The submegawatt Direct Fuel Cell power plant, supplied by FuelCell Energy, will be installed at the Dry Creek Water Reclamation Facility in Cheyenne in Spring 2013. The plant will provide 200 kW of power to the data center, housed in a modular IT preassembled component with servers to recreate a data center environment. Power not used by the data center will be provided to the water reclamation facility. In the event of a grid outage, the data plant project and fuel cell will be configured to operate independently to provide continuous power. The city of Cheyenne applied for a $1.5 million Community Readiness grant through the Wyoming Business Council to fund the needed infrastructure to support the data center project.

Boston, Massachusetts: MassDEP Creates Ad Web Page

The Massachusetts Department of Environmental Protection (MassDEP) recently created a new web page on anaerobic digestion that features resources for anaerobic digester project developers and facility operators. For example, the page links to a subpage, Financial & Technical Assistance for Anaerobic Digestion Projects, which provides a matrix identifying a number of grant, loan and other programs available from both government agencies and quasi-public organizations for the diversion of organic material and the responsible siting of anaerobic digestion. This tool helps users determine which programs are most applicable to different project stages and types of sites. There also is a link to members of the Massachusetts Clean Energy Support Teams, state employees who provide “one-stop shopping” to help parties navigate the environmental requirements of clean energy projects, including permitting and environmental regulations and standards.

Anaerobic digestion also received a boost recently from Massachusetts Governor DeVal Patrick, who vowed in a clean energy speech to make Massachusetts No. 1 in biogas production. In August, Governor Patrick joined legislators and advocates to sign Senate Bill (S. 2395), “An Act Relative to Competitively Priced Electricity in the Commonwealth.” The bill includes the extension of long-term contracts between the utilities and renewable energy companies, which aim to keep the supply of renewable energy credits in balance with the growing demand and ultimately lead to significant cost savings for ratepayers. It also raises the cap on net metering, where generators of renewable energy can run their meters backwards and sell power back to the distribution company for credits — providing an important monetary incentive for the installation of renewable energy. The current statewide cap for net metering of 3 percent is close to being reached. S. 2395 raises the total net metering cap from 3 to 6 percent of the utilities’ peak load. Anaerobic digestion also was added to the list of eligible technologies able to net meter. The new MassDEP webpage address is: www.mass.gov/dep/ energy/cerpanaerobicdigestion.htm.

New York, New York: RNG As Transportation Solution

A newly released publication, “Renewable Natural Gas (RNG): The Solution to a Major Transportation Challenge,” reports that use of RNG as a vehicle fuel is a technologically viable alternative to relying exclusively on petroleum-based fuels for transportation. The publication was prepared by Energy Vision, a New York-based energy research organization, and CALSTART, a California-based advocate of clean transportation technologies. “Today we can turn this country’s expensive organic waste burden into a clean vehicle fuel solution,” says Joanna Underwood, president of Energy Vision, adding that waste-generated biogas, along with fossil-based natural gas are the “only options for displacing significant amounts of oil.”

Eight RNG projects are described in the report to illustrate what is already being accomplished on this “green fuel” frontier. These include three anaerobic digester facilities — Fair Oaks Dairy in Indiana, the Janesville, Wisconsin wastewater treatment plant and the Ohio Bio-Energy Digester in Columbus — as well as five landfills generating RNG from captured biogas. The Fair Oaks Dairy, for example, is producing fuel equal to 1.5 million diesel gallons/year. The dairy is running 42 large milk tanker trucks on RNG, a switch that is expected to yield more than $2.5 million annually in fuel cost savings. “Communities of 40,000 or more may generate enough organics to produce fuel for their bus and truck fleets and more,” notes Underwood. “But smaller communities, which have neighboring towns and nearby dairies, hotels, food processing plants or other organic waste sources, should begin to join together and explore pooling their wastes and investing in production of the fuel.”

The Energy Vision/CALSTART report summarizes nine major obstacles to communities and companies that want to produce RNG for vehicle fuel. These include the upfront costs of constructing anaerobic digesters and the technology needed to refine the biogas into fuel, existing standards that make it difficult to transport RNG through natural gas pipelines, and provisions in the U.S. Tax Code that reward production of biogas for power generation but not for vehicle fuel. The new publication can be downloaded at www. energy-vision.org/.

Rutland, Vermont: Cow Power On The Big Screen

Film students from Emerson College in Boston recently released a trailer of their new documentary, “Cow Power: The Film,” which focuses on the history and science behind the few places in the United States that offer electricity generated from cow manure via anaerobic digestion. It features the Cow Power project launched by Central Vermont Public Service (now Green Mountain Power (GMP)) in 2004, highlighting dairy farms in Vermont that have utilized the incentive program to install anaerobic digesters. Utility customers pay an additional 4 cents/kWh to participate in the program. GMP pays the farmer for the energy at rates set by the state, plus the Cow Power charge of 4 cents for the environmental and renewable benefits of the generation. Twelve farms generating electricity via AD are currently participating in the program. A host of local Vermont businesses like LongTrail Brewery, Vermont T’s, Green Mountain College and Middlebury College have joined other customers in paying the monthly premium to support the project. (To learn more about the Cow Power program, see “Farm Digesters For Small Dairies in Vermont,” April 2008 and “Vermont Builds Anaerobic Digestion Capacity,” October 2011, available at www.biocycle.net).“The goal of the students is to spread the word about the film, and motivate others to work with dairy farmers across the country to copy the Cow Power program and build more projects everywhere,” says David Dunn, manager of Cow Power. “They would also like to grow their email list in order to gain the attention from the documentary industry to get the movie out in distribution. They need a minimum of about 10,000 people on their list.” To watch the trailer and sign up for the email list, visit www.cowpowerthefilm.com. The documentary will be released in 2013.

Alexandria, Virginia: Barriers To Biogas Use At WWTPs

In 2011, the Water Environment Research Federation (WERF) and the New York State Energy Research and Development Authority (NYSERDA) conducted a study to determine what barriers wastewater utilities face in implementing combined heat and power projects. An RFP to conduct the study was awarded to a team lead by Brown and Caldwell and Black & Veatch. The project team developed an online survey to determine the most significant barriers facing utilities. The survey was distributed nationally and completed by more than 200 respondents. “Many of the findings were not surprising,” note the report authors. “Of the 10 categories introduced as potential barriers at the beginning of the project, nine were deemed significant. However, it became clear that economic barriers — inadequate payback/economics and lack of available capital — were dominant. Other barriers fell into two categories: policy factors such as regulatory permitting, and human factors, such as decision making.”

While public agencies’ decision-making bureaucracy/configuration can hinder biogas use, the authors discovered “a surprisingly high percentage of respondents from smaller capacity facilities have found means to justify biogas use projects. As such, it seems that textbook 5- or 10-million gallons/day lower-capacity [treatment plant] barriers can be overcome with creative thinking.” The research also identified considerably more interest and investment in biogas use over the past five years than in the prior years, as well as greater interest on the part of wastewater utilities for enhanced plant efficiency, operational cost reduction and sustainability — all of which support biogas use projects.

The core research team also included the North East Biogas and Residuals Association, Hemenway, Inc. and Ross & Associates Environmental Consulting. The final report, “Barriers to Biogas Use for Renewable Energy,” is available from WERF (www.werf.org).

Compton, California: Digester At Supermarket Food Distribution Center

In 2011, the Ralph’s and Food 4 Less distribution center in Compton, located next to a creamery, began construction of an on-site Resource Recovery System to convert unsold food into renewable energy to fuel the facility. The anaerobic digester is designed to process 55,000 tons/year of organics and cardboard and creamery wastewater, according to information in Kroger’s 2012 sustainability report. (Kroger is the parent company of Ralph’s and Food 4 Less.) “Because of this system’s location, it will optimize existing distribution and transportation networks by eliminating current diesel truck trips, improving associated air quality, and generating on-site renewable distributed energy and wastewater treatment,” notes the Kroger report. The distribution center installed three 250 kW microturbines to produce electricity to meet on-site demand.