Michigan State University integrates AD with other biological processes to convert organic wastes into value-added fuels that are needed to enhance the economic and environmental performance of organic waste management.

Louis Faivor, Wei Liao and Dana Kirk

BioCycle May 2013, Vol. 54, No. 5, p. 29

29aMSU’s 225,000-gallon capacity plug-flow anaerobic digester (top) processes dairy manure, campus food waste and nonedible eggs from the university’s poultry farm. Liquid separated from the digested solids will be the nutrient source for the algal raceways (above), which are adjacent to the digester.

From a MSU campus sustainability perspective, detailed goals have been established to reduce waste and greenhouse gas emissions while increasing use of renewable energy on campus. Adopted in April 2012 by the MSU Board of Trustees, the Energy Transition Plan serves as a guide for the university towards its goal of 100 percent of its energy requirements being supplied by renewable sources. In addition to the animal waste production on campus farms, another major organic waste stream available on campus is food from campus cafeterias. Around 1,000 to 1,500 tons/year of food waste are generated from the over 150,000 meals served per week on campus during the academic year, and also needs to be sustainably managed.

While anaerobic digestion (AD) is effective in managing organics like those generated at MSU, the high capital costs of current AD technology (approximately $600 to $1,200/cow depending on farm size and digester technology) and the low monetary value of renewable energy and environmental benefits create poor financial conditions and limit widespread adoption. Innovatively integrating AD with other biological processes to convert organic wastes into value-added fuels and chemicals are urgently needed to enhance the economic and environmental performance of organic waste management. In response to the need to develop integrated systems, the MSU research group has been studying anaerobic digestion and related downstream processes. Preliminary lab-scale studies indicate that the solid digestate (AD fiber) has an improved carbohydrate profile that can be a good feedstock for biorefining for fuel and chemical production (Teater et al. 2011; Yue et al. 2010; Yue et al. 2011), and algae cultured on liquid digestate can be used as a supplemental feedstock to significantly improve the hydrolyzibility of AD fiber to produce mono-sugars (Chen et al. 2012).

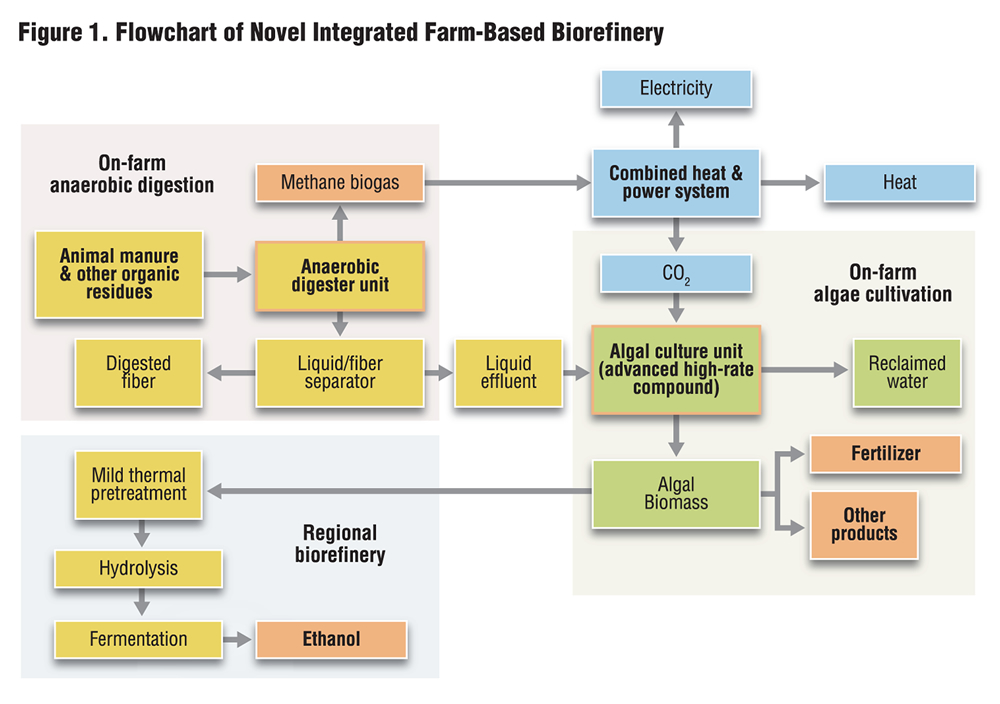

Given these new findings, a novel integrated farm-based biorefining concept has been developed. The integrated biorefining system includes three main unit operations: anaerobic digestion, algal cultivation, and bioethanol production (Figure 1). Anaerobic digestion converts animal manure and other organic residues (such as bedding materials and food wastes) into methane gas and AD treated fiber. Open-pond algal cultivation then takes AD liquid effluent to accumulate algal biomass, sequester CO2 from methane combustion, and further reclaim the water. The final piece of the farm-based biorefinery is using AD treated fiber (solids) and the algal biomass as feedstocks to produce cellulosic ethanol with improved efficiency.

MSU Biorefinery

Using the integrated farm-based biorefining concept, a full-scale AD and algal cultivation facility was designed and constructed at the MSU campus using a grant from the Michigan Public Services Commission (MPSC) to demonstrate the integrated concept, improve campus sustainability, and provide a teaching and research tool for design and optimization of larger integrated systems. The facility is located at MSU’s dairy farm, and includes an anaerobic digester, solid-liquid separator, algal raceways and boiler. The digester, which began operating in September 2011, is an unmixed and U-shape plug flow digester with an effective volume of 225,000 gallons, and is covered by EPDM (ethylene propylene diene monomer) rubber. Biogas produced is combusted in a boiler that provides heat to maintain the digester and surrounding infrastructure.

Once the solid-liquid screw press separator comes on line this summer, the solids will be incorporated into the MSU composting system, a modified in-vessel system consisting of three 120 foot aerated bays where piles are turned mechanically. The separated liquid (filtrate) will become the nutrient source for the algal raceways. There are two raceways at the site — the large raceway open pond (270-feet by 50-feet) and the small pond (90-feet by10-feet). Both ponds are three feet deep with approximately 14-inches of active depth. Total footprint of the algal raceways and digester is about one acre. The algae raceway, not fully operational at this time, was seeded at the end of 2012 with some unseparated digester material along with some algae cultures to initiate the process. Regular feeding of the filtrate will begin when the separator is operational.

The farm-based biorefinery facility, along with the MSU Anaerobic Digestion Research and Education Center (ADREC), comprise a research complex working towards the advancement of the AD technology with an emphasis on small and medium sized farms. The MSU AD and algal cultivation facility has been operated by the MSU Department of Biosystems and Agricultural Engineering.

Electrical generation was not considered as biogas production could be interrupted as research activities are carried out. In addition, the cost of the interconnection was not justified by the energy potential of the system. However, a new project aimed directly at addressing campus sustainability is the South Campus Anaerobic Digester (SCAD) that is currently under construction and will be operated by the MSU Land Management Office and generate energy for the campus. Completion and start-up are expected in early July 2013. The digester, supplied by Anaergia, will utilize approximately 17,000 tons/year of mixed feedstock including livestock manure, campus food waste, food processing waste and fats, oils and grease (FOG). It is anticipated that the completed mixed digester will provide enough biogas to continuously generate about 450 kW of electricity for campus.

While each digester system has its own functions and research goals, their operation will be integrated to some extent. For example, the research digester boiler will supply hot water to the SCAD during start-up; once the generator is operational, biogas from the research facility will supplement the SCAD system. Effluent from both systems will be separated into solid and liquid fractions with the solids going to composting and the filtrate — excepting for the 5 to 10 percent to be used in the algal raceways — kept in gas tight storage until land application can occur. (Eventually, the solids could be used as a cellulosic ethanol feedstock.)

Feedstocks And Operation

Food waste, dairy manure and nonedible eggs from the poultry farm comprise the base blend of feedstock for the farm’s anaerobic digester. Other feedstocks received periodically include waste potatoes, glycerin, beef cattle manure and poultry litter. During 2012, the digester received approximately 750 tons of manure, 330 tons of food waste and 4 tons of eggs (the ratio of animal manure to food waste is approximately 70:30). Approximately 38 percent of the food waste collected was pulped material from Brody Hall, the lone dining hall on campus with equipment to pulp its pre and postconsumer food waste. Starting in March 2012, a program to divert preconsumer food waste (both kitchen preparation and line waste) was implemented in six dining halls where wheeled carts are used to collect the organics. The preconsumer program was continued for the entire fall semester of 2012 and accounted for 62 percent of the total food waste diverted to the digester. Material containing bones was the only food waste excluded. Tons collected peaked in October 2012 at 48 tons (96,000 lbs) during the month.

The digester is fed once per day and is operated at a mesophillic condition. The feed pit has a capacity of about 5,500 gallons and is kept partially full with digester effluent. When new material is delivered, it is mixed with the effluent through the agitation function of a vertical chopping pump to decrease the particle size of the manure and food waste and enable the material to be pumped into the digester.

Because food waste from the dining halls is a major constituent of the influent material, the organic loading rate (OLR) fluctuates depending on the academic calendar. Analyzed on a monthly basis, the highest OLR occurred in January 2013 at 0.094 lb VS/ft3-d (lbs volatile solids per cubic foot/day) when the food waste program was expanded to its fullest extent to date. The lowest OLR occurred in May 2012, immediately following the end of the spring semester and the subsequent exodus of students from campus. To this point, the digester has proven to be remarkably stable as long as mesophillic temperatures can be maintained. Any type of upset, despite periods of little to no food waste followed by periods of significant organic loading, has been avoided.

Effluent is removed at predetermined intervals for land application on MSU research farmland. Once the separator comes on line, a portion of the solids will be used as feedstock for biofuels production. As noted, a portion of liquid effluent (1,000 gallons) will be fed to the raceways to culture algae and reclaim water.

The algal cultivation will be operated six to eight months per year from spring to fall. The raceways are continuously mixed by paddle wheels. The algal growth rate is 0.03 g/L/day. Two receiving pits are installed next to the raceway. The liquid (algal biomass and water) overflows into the receiving pits and the algal biomass is harvested weekly from the receiving pits. A small portion is taken for studying algal biomass utilization; the remainder is pumped back to the digester as a nutrient supplement. The reclaimed water from the receiving pits has much less nutrient content (Total nitrogen <200 mg/L and Total phosphorus < 2mg/L) compared to the liquid effluent from anaerobic digestion (more than 3,000 mg/L of TN, and 500 mg/L of TP), which requires much less acreage for land application of the liquid effluent.

A biogas flow meter was installed to track biogas being utilized by the boiler. Throughout the 2012 spring semester, biogas utilization ranged from 100 to 600 standard cubic feet per hour (SCFH) on a daily average. Biogas production slowed during the summer months due to the low student population. However, starting in late August 2012, biogas use stabilized in the range of 500 to 600 SCFH. Overall, the consistent addition of preconsumer food waste resulted in an increase in the methane concentration of the biogas by about 4 percent, going from 53 percent during the period of January to March to 57.5 percent from August to December.

Fuel, Biomass And Heat Production

Based on the operation of the research facility and experimental lab results, the integrated biorefining concept is capable of producing electricity, bioethanol and fertilizer (algal biomass), and simultaneously reclaiming water. A mass and energy balance analysis has elucidated that the integrated biorefinery can generate 40 kg ethanol/metric dry ton of mixed feedstock (dry weight ratio of dairy manure to food waste was 70:30), 115 kg methane per metric ton dry feedstock, and 20 kg algal biomass per metric ton dry feedstock. The solids content in the settled algal biomass is around 0.5 percent TS. It will be further concentrated by a centrifuge to raise the solids content to 5 percent, and then be used without drying for the ethanol production — a big advantage for algal biomass utilization. In addition, fresh water input is not necessary for the integrated system. The implementation of algal cultivation on AD liquid effluent can reclaim 8,000 kg water/metric ton dry manure and recycle them back to the system for dilution and other nonpotable water uses.

Considering the 120 million dry tons of cattle and dairy manure produced annually in the U.S. and mixing with 51 million tons of food and other organic wastes, the implementation of the integrated biorefinery concept on these waste streams can potentially generate 1.65 billion gallons of ethanol, 0.7 million tons of algal biomass, and 700 petajoule of heat from burning the methane gas. In addition, biofuel substitution of fossil fuels by methane and bioethanol from the integrated system can sequester a total amount of 10 million tons of carbon annually in the United States.

A new business model of animal residue utilization/bioethanol production can be established based on the integrated biorefining concept that begins with utilization of AD. A regional bioethanol production plant could be centralized within cattle/dairy farmland. To produce 20 million gallons (6 million kg) per year of ethanol requires 2,150 tons/day of dry digested fiber (containing 32% cellulose) as feedstock. Medium size cattle/dairy farms with 1,000 cows generate 8.5 dry tons/day of manure. By using AD and algal cultivation to treat this manure, each farm can produce 4.5 tons/day of dry AD fiber and 170 kg of dry algal biomass.

Implementation of the integrated system on a national scale could result in over eighty 20 million gallon regional cellulosic ethanol plants using the AD fiber as feedstock. The waste streams from ethanol production such as stillage can be transported back to the farm as animal feed or AD influent. In addition, the sustainability of animal operations will be improved by reducing the GHG emissions, potential surface and ground water pollution and noxious odor, while at the same time generating AD fiber, algal biomass as biorefining feedstock, and electricity that will contribute to farm income. The integration of AD and cellulosic ethanol production results in improved system efficiency that also yields electricity, heat, fertilizer and other products. This would increase the practical feasibility of anaerobic digestion and algal cultivation to a wider spectrum of agricultural operations. MSU continues to seek support to construct the ethanol facility, which will complete the integrated farm-based biorefinery concept demonstration facility.

Louis Faivor, Research Technologist and graduate student, Dr. Wei Liao, professional engineer and Assistant Professor, and Dana Kirk, Research Specialist, are all with the Department of Biosystems and Agricultural Engineering at Michigan State University.