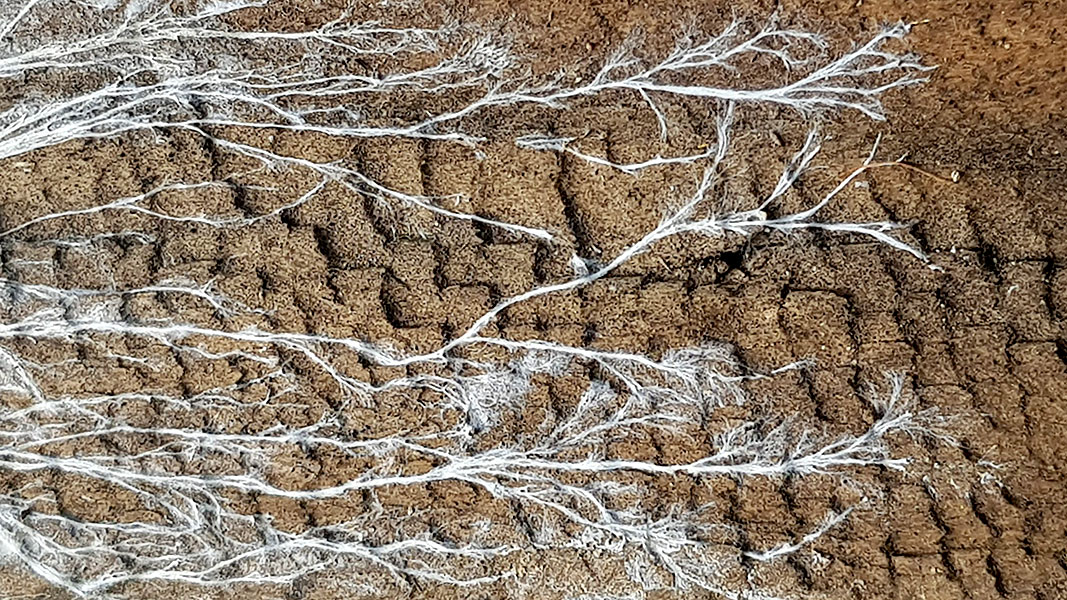

Top: White rot fungi on wood. Photo courtesy of Johannes Biala

Joshua Bennett-Jones, Johannes Biala and Angus Johnston

The value of using microbial inoculants in composting has been debated for many years. The diversity of opinion on this topic among professionals and in the scientific literature is probably not surprising given the diversity of organic residues that are composted, the constantly changing trophic and environmental conditions during the composting process, and the range of compost inoculants available in the market, matched by the equally wide range of benefits they are meant to deliver.

Inoculation has been promoted as a method to accelerate the composting process, increase stabilization and maturity of the final product, promote specific microbial consortiums, degrade specific compounds, reduce phytotoxicity, increase control of pathogens, and promote seed germination (Zainudin et al. 2022, Coker 2019). Composting, however, is a highly heterogenous process due to the variability in organic parent materials, the environmental conditions the composting process is operated under, and the development of indigenous microbial populations which are highly competitive (Fan et al. 2017). These factors, particularly within open composting systems, can result in a lack of significant effects of microbial inoculation, such as reported by Yadav et al. (1982) during the composting of vegetation residues, cattle manure and wheat straw inoculated with various fungal strains.

In a review, Fan et al. (2018) indicated substantial variations in results due to parent materials and indigenous microbial populations, with microbial inoculation having a significantly positive effect on lignocellulosic waste materials but having nearly no effect on municipal solid waste (MSW). The difference, they noted, was due to MSW consisting predominantly of food and green waste products which typically have a high proportion of readily available organic compounds able to be utilized by the indigenous microbial populations driving competition. Due to the variation in results and reproducibility, substantial amounts of research have gone into developing inoculation strategies to accelerate the composting process and produce a high quality, mature product such as developing specific cultures and identifying key phases to apply inoculum (Rastogi et al. 2020).

Inoculation Of Lignocellulosic Waste

Palm fronds (Eliasjorge4, CC BY 3.0, via Wikimedia Commons)

Adding inoculants to feedstock for marginal gain, such as merely speeding up the composting process, might seem frivolous compared to situations where the use of microbial inoculants could be key to solving major organic waste problems. In areas that have an abundance of dry residues with high lignocellulosic content but are lacking nitrogen-rich materials, such as animal manures, biosolids, green vegetation or food residues, cocomposting of these materials is not an option. In locations such as the United States Southwest (e.g., Texas), North Africa, or Pacific islands where large quantities of palm fronds but little else is available, degrading disposed lignocellulosic materials poses a major challenge.

Inoculation of materials that have a high lignocellulosic content such as palm fronds with suitable microbial strains could greatly enhance their speedy breakdown and transformation into valuable soil amendments. Microorganisms which specifically degrade lignin, cellulose and hemicellulose include Phanerochaete chyrsosporium, Ganoderma lucidum, Ceriporia lacerata, Cyathus stercoreus, Ceriporiopsis subvermispora, Pycnoporus cinnabarinus, Pleurotus ostreatus, Bacillus subtilis, Bacillus cereus, Klebsiella pneumoniae, Aspergillus fumigatus, Aspergillus nomius, Aspergillus niger and Micrococcus luteus (Piñeros-Castro and Velásquez-Lozano 2014; Bala et al. 2018).

Phanerochaete chrysporium on wood chip. Photo courtesy of cymobase

Elsayed et al. (2021) described the degradation pathway of cellulosic material through the production of cellulases and xylanases, both of which hydrolyze the cellulose and hemicellulose within the plant material, making it accessible for further breakdown into glucose and pentose. Xiao et al. (2013) observed the degradation of lignocellulosic materials from birch trees by the white rot fungi Ganoderma lucidum. They found that G. lucidum contains all the necessary biochemical pathways to produce enzymes that degrade the components of lignocellulosic materials. These enzymes were also found to break the covalent bonds between the lignocellulos’ components, depolymerize lignin, decrease cellulose crystalline, and partially hydrolyze hemicelluloses.

Microbial degradation processes are able to change the biochemical and physical characteristics of discarded biomass, as evidenced by the molecular weight reduction (42%) of hemicellulose during the degradation of birch. Pineros-Castro and Velasquez-Lozano (2014) inoculated empty fruit bunches (EFB) formed during production of palm oil with P. chrysosporium and P. ostreatus to observe the reduction in biomass. The P. chrysosporium treatment reduced the biomass weight by 23.2% and 33.4% within two and four weeks respectively, and P. ostreatus treatment reduced biomass by 6.6% and 42.7% after two and four weeks, respectively. The different degradation patterns were attributed to P. ostreatus being selective for delignification as cellulose degradation did not begin until after week three while P. chrysosporium simultaneously removes lignin and structural carbohydrates, degrading the material homogeneously.

Yeoh et al. (2011) reported the accelerated degradation of palm EFB when they chipped materials to 2 to 4 cm (0.8 inches-1.6 inches) particle size and applied a consortium of microbes consisting of Agromonas sp., Aspergillus sp., Azotobacter sp., Bacillus sp., Cellulomonas sp., Chaetomium sp., Clostridium sp., Coprinus sp., Microbispora sp., Penicillium sp., Pseudomonas sp., Thermoactinomyces sp., Trichoderma sp., and Trichurus sp. They reported a reduction in composting time to maturity by four weeks, reaching a stable product after five weeks with a C:N ratio below 20.

Phukongchai et al. (2022) inoculated sugar cane straw with cellulolytic and ligninolytic microorganisms consisting of Chaetomium sp., Scytalidium sp., Corynascus sp., Streptomyces sp., and Bacillus sp. to aid decomposition in tropical sandy soils. They identified that soil incorporation of inoculated cane straw provided higher weight loss (72% after 32 weeks) than incorporation of non-inoculated straw or mulching. They also found short term increases in soil carbon (18.8%) and total nitrogen (14.3%) compared to unamended soil.

Simply piling up palm fronds and applying inoculants is unlikely to deliver the desired outcome. For such inoculants to work, the surface area of materials to be degraded needs to be increased by chipping to particle sizes between 2 to 4 cm. Moisture levels should be maintained between 55% and 75% throughout the degradation process, and pH levels should range between 5.0 and 7.5.

Inoculation with Effective Microorganisms

Due to the recalcitrance of materials with high lignocellulosic contents such as palm EFB, palm trunks and palm fronds, investigation into the acceleration of degradation through inoculation with commercial Effective Microorganisms (EM) such as EM1 has been trialled. EM1 is reported to consist of a consortium of microorganisms with the majority belonging to lactic acid bacteria, photosynthetic bacteria, fungi, yeasts and actinomycetes such as Lactobacillus sp., Rhodopseudomonas sp., Bacillus sp., and Saccharomyces sp (Higa and Parr, 1994). Lim et al. (2015), for example, applied the commercial inoculant EM1 to palm EFB mixed with urea and molasses to accelerate the composting process. The inoculation accelerated the composting process by seven days, reduced loss of nitrogen by 53.9%, and increased total organic carbon loss by 65.7% compared to the uninoculated materials.

Yu et al. (2018) assessed the effect of EMs, P. chrysosporium and a combination of 2 Bacillus sp. and an Aspergillus sp., on the degradation of vegetation residues mixed with urea. P. chrysosporium was found to affect the highest lignin degradation at 25.9%, followed by the combined inoculum at 23.9% and EMs at 19.4%. Cellulose degradation was found to be highest with the combined inoculum at 41.7%, followed by EMs at 40.71% and P. chrysosporium at 34.3%.

A review of composting with EMs concluded that research in this field needs to be considered on a case-by-case basis (Fan et al. 2018). It was reported that the effectiveness of inoculation with EMs was highly variable and the potential for enhancing the composting process was dependent on the materials being degraded. For instance, composting the inoculated organic portion of MSW was reported as enhancing the process in only 38% of studies. The main benefits were volume reduction, odor control, increased microbial population and increased humification.

In comparison, composting of inoculated lignocellulosic materials with EMs enhanced the process in 80% of studies. The main benefits were enhanced temperature, enzyme activity and humification; decreased total organic carbon and C:N ratio; and increased nitrogen and phosphorus content. Due to the specific operating conditions required to provide a favorable environment for the colonization and effective function of the inoculum — and added economic costs required to successfully enhance composting through inoculation — they concluded that optimizing composting conditions for both lignocellulosic materials and MSW, such as C:N ratio, aeration and moisture content, to provide favorable conditions for the growth of the indigenous microbial populations that also break down such materials, would be a more feasible approach in achieving desired physicochemical characteristics of generated products.

Another, more recent review by Safwat and Matta (2021) also highlighted the mixed results when EMs were used to enhance the composting process. They found negligible results when used for composting chicken manure, pine bark, goat manure, sewage sludge and banana residue. However, they found reports of positive results when material such as chrysanthemum and water hyacinth residuals, vegetation residues, food scraps, paper and household organics were composted. The review concluded that while EMs can provide beneficial outcomes, when applied to composting the results are highly variable and often underperform, yielding negligible benefits.

Process Optimization

Due to the heterogeneity of the feedstock(s), the composting process and the indigenous microbial populations, applying inoculants to enhance the process and physicochemical characteristics of generated products needs to be carefully considered as to why inoculation might be required and what benefits are being sought. Optimizing the composting process through better management of the operating conditions is generally going to provide an enhanced environment and end product without the need for inoculation due to the facilitation of indigenous microbial populations. Optimizing operating conditions such as moisture content, aeration, pH and C:N ratio is also required for the successful application of inoculums.

Therefore, if considering utilization of microbial inoculation within organics management it would be beneficial to first implement an optimized composting process that facilitates growth of indigenous microbial populations and culturing the indigenous microbes to acquire the desired species that facilitate enhanced composting and improved compost characteristics. This was observed by Karnchanawong and Nissaikla (2014), where addition of mature compost from an optimized composting process at a rate of 5% was found to outperform the addition of commercial inoculums through selection for microorganisms that were adapted to the operating conditions and feedstock materials. Formowitz et, al. (2007) noted similar results with inoculation resulting in no increases to the compost quality due to the inoculum being unable to outcompete the indigenous microbial community which developed within composts with optimized conditions.

Joshua Bennett-Jones and Johannes Biala are with the Centre for Recycling of Organic Waste and Nutrients at the University of Queensland in Gatton, Australia. Angus Johnston is with New Resource Solutions in Speers Point, Australiua.