Mango Materials’ biopolymer pellets can be formed into films or fibers that are woven or knitted into mesh netting. Photo courtesy of Mango Materials.

The Schmidt Marine Coastal Pollution Challenge solicited innovative technology solutions to address the urgent need to eliminate the causes and reduce the impact of coastal pollution, specifically nitrogen and phosphorous from sources like wastewater and agricultural runoff that are a major driver of harmful algal blooms and fish kills. The program is providing the winners’ projects more than $1.5 million in funding over two years to advance their technologies and demonstrate commercial viability.

“Coastal pollution — everything from wastewater to torrents of plastics to nitrogen — is flooding our ocean and destroying its fragile and valuable ecosystems,”said Wendy Schmidt, founder of Schmidt Marine Technology Partners and president of The Schmidt Family Foundation, when announcing the winners. “We created this challenge to encourage and identify innovative solutions that reduce a critical component of that pollution, and to invest in their development so they can be brought to market and scale.”

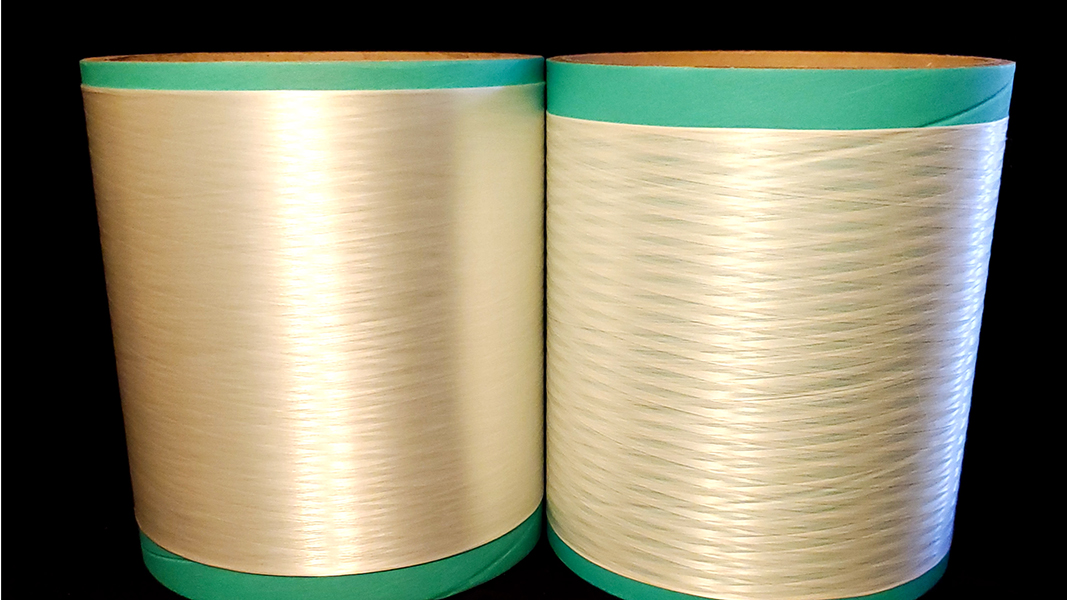

One of the four winners, San Francisco-based Mango Materials, has developed full-circle fermentation technology that can convert methane from landfills, anaerobic digestion and other sources into a biodegradable plastic alternative. Funding will allow the team to explore use of this material to encourage growth of bacteria that consume nutrient pollution. Possible applications include creation of mesh materials to line banks or tributaries where runoff leads to dangerous levels of nitrogen and phosphorus. The mesh would act as a scaffold on which the bacteria grow; the material itself provides the food needed for the bacteria growth that ultimately removes nutrients. Mango Materials also will study the potential application in aquaculture cages and nets to reduce the need for conventional plastics, while also encouraging bacteria growth that would reduce harmful nutrient releases from fish waste.

Takachar has organic certification and has blended the biochar with compost and/or manure for organic growers. Photo by Samuel Rigu

Another winner, Berkeley (CA)-based Takachar, has developed low-cost machines that use organic material like sugar cane pulp and rice husks to create biochar fertilizer blends in rural villages — enabling farmers to generate their own nutrient-rich fertilizer on-site that improves soil health and continues providing needed nutrients over the long term rather than washing away and entering waterways as conventional fertilizers do. “When working with farmers, the first step is to conduct a soil test to identify any deficiencies,” explains Kevin Kung, founder of Takachar. “Then the blending is done that is responsive to these deficiencies. We do have organic certification and have blended compost and/or manure for farmers, especially those who wish to be organic. Other more conventional nutrient components have been blended in other cases.”

The final two winning projects are focused on the development of low-cost nitrogen sensors using different technologies. Long-term, high-resolution sensing of nitrates is essential to identify the most troublesome pollution sources that plague coastal waters and could be used in other waterways and in wastewater treatment plants. Current sensors cost thousands of dollars and can be difficult to use reliably in murky coastal waters, making it prohibitively expensive and difficult to obtain the necessary data. Station C, created by physicist and principal investigator of the Future Ocean Lab at MIT Allan Adams, is developing an optical sensor that uses light and acoustics to detect nitrogen, phosphorus and other components. And Amy Mueller, assistant professor in the colleges of science and engineering at Northeastern University, is working to create a simple and inexpensive nitrogen sensor using 3D printing and machine learning to develop an “electronic tongue” microchip with electro-chemical probes.