The Biodegradable Products Institute (BPI) and BioCycle convened a stakeholder workshop series in early 2021, which brought together compost manufacturers, municipalities, foodservice operators, and compostable product manufacturers to identify existing barriers to the acceptance and successful processing of compostable products, along with future state definitions and initial project scoping for how to overcome them. One of those barriers was “Compostability Standards,” defined as “products meeting ASTM standards not breaking down quickly enough in real world environments.” Workshop attendees expressed 100% support for a “collaborative program designed to generate comprehensive data on the performance of certified products in composting facility systems,” making it the most supported proposed action item of the entire workshop series (see Roadmap and Action Plan for details).

With consensus established, the “Field Validation Program” project was initiated by BPI with the goal of “providing composters with enough information on real world performance to trust that products meeting ASTM standards will break down in facilities designed to accept food scraps and packaging. The starting point was to identify and consolidate all of the publicly available data BPI could find on the performance of compostable products in real world composting environments. The data was collected in April 2021 from information shared either publicly or directly by the Compost Manufacturing Alliance (CMA; United States), and two composting associations — Cre (Ireland), and CIC (Italy). The findings were compiled in a report, “Review of Publicly Available Field Testing Results and Programs,” posted on the BPI website in January 2022.

“The conclusions and opinions of this report are solely those of BPI and are not endorsed by the CMA or other sources of the data,” notes BPI, adding that the data republished in its report does not include failed field tests or information on test conditions beyond process time. Operating conditions such as temperature, moisture, C:N ratio, and pH were not reported. “As a result, the existing data alone does not provide a complete picture,” explains BPI. “All of these variables are important for understanding whether the field test was representative. A controlled field test is required to validate that a specific test correlates to full-scale composting processes.” All products tested are certified to ASTM, EN, or ISO standards; 1071 data points are included from approximately 1,000 field tests. These products represent the majority of physical forms and material composition of certified products currently in the market today. Molded fiber products are a notable exception to this and are not represented in the data.

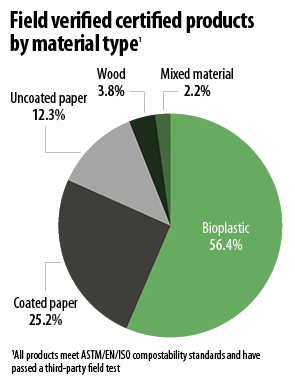

The report organizes products by field testing time frame, material type, and product category to provide different ways of understanding the scope and breadth of what has been tested and approved to date. The pie chart shows the field verified products tested. Nearly 57% of all field verified products belong to the Bioplastic category, which includes clear cold cups, food containers, cutlery, bags and other non-fiber products; 25% belong to the Coated Paper category and includes: paper hot cups and soup cups, lined food trays, and other products utilizing a fiber base with a bioplastic (or other) compostable lining. The majority (85%) of publicly available data is for products that have passed field tests with 49-day time frames, which suggests that the 12-week (84-90 days) disintegration tests in ASTM, EN, and ISO standards may still be sufficiently conservative for indicating real world performance in a majority of products being certified today, despite shorter real world processing times.

The report organizes products by field testing time frame, material type, and product category to provide different ways of understanding the scope and breadth of what has been tested and approved to date. The pie chart shows the field verified products tested. Nearly 57% of all field verified products belong to the Bioplastic category, which includes clear cold cups, food containers, cutlery, bags and other non-fiber products; 25% belong to the Coated Paper category and includes: paper hot cups and soup cups, lined food trays, and other products utilizing a fiber base with a bioplastic (or other) compostable lining. The majority (85%) of publicly available data is for products that have passed field tests with 49-day time frames, which suggests that the 12-week (84-90 days) disintegration tests in ASTM, EN, and ISO standards may still be sufficiently conservative for indicating real world performance in a majority of products being certified today, despite shorter real world processing times.

In reviewing a limited amount of raw field test data confidentially submitted by BPI members in support of this report, it appears that paper and fiber items, despite being “generally recognized as compostable” in many programs, may have more difficulty passing both the 49- and 90-day tests. This includes molded fiber products without PFAS; molded fiber as a material type is almost entirely absent from the publicly available data. Similarly, the limited raw data BPI reviewed showed bioplastic coatings on paper (e.g. hot cups) sufficiently breaking down, but leaving behind a mostly intact paper substrate. Partially degraded paper and fiber items may be less concerning to composters than partially degraded plastic-like items, since they are not typically part of the contamination limits on finished compost regulated in places like California and Canada. But the differences between lab and real world performance may shed light on testing protocols.

“This review of both publicly and privately available data highlights the need for additional research to identify what may lead items to not break down, including isolation of root causes,” explains Rhodes Yepsen, BPI’s Executive Director. “In some cases, the root cause may be specific to a bioplastic or a lignocellulosic ingredient. In other cases, it may stem from the specific composting environment and its conditions. Understanding root causes would prevent repeated field testing of items that are working (such as the range of bioplastic items documented in the report), and focus on identifying characteristics in items that are not consistently breaking down that may be limiting factors (e.g. polymer crystallinity, lignin content, polymer molecular weight/polydispersity, sample surface to volume ratio, presence of additives, etc.).” Yepsen adds that BPI recently registered an ASTM “work item” to create a standardized field testing protocol, and launched a collaboration “forum” to discuss the draft before it goes to ballot to become a new standard. The process will be co-led with CMA.