Jana White

BioCycle October 2015

As the South Carolina Department of Health and Environmental Control (DHEC) began to assess its options for increasing organics diversion several years ago, one of the first places it looked was its composting regulation. Since the effective date of the original regulation in 1993, it was difficult for DHEC to permit composting facilities that wished to process more than yard trimmings and land clearing debris. Facilities could obtain a Research, Demonstration and Development (RD&D) permit, however the permit had a two-year limit and was required to be unique from other applicants. Few composters were eager to invest in a facility with the potential to lose the permit after two years.

Composters also were given the opportunity to operate under a composting permit with special conditions, but applicants worried about the uncertainty of a permit that included operational, location and testing standards not clearly outlined by regulation.

South Carolina began revision of its composting regulation focused on three specific goals:

1) Develop a regulation to reduce the amount of material disposed in landfills and include more types of material that may be composted by providing waste generators options for managing a wider variety of organics, particularly food waste.

2) Encourage production of high quality compost by updating standards for compost production and testing.

3) Reduce barriers or perceived barriers to operating composting facilities in the state (perhaps the most important goal).

The revision was led by DHEC and included a stakeholder process involving the composting industry, U.S. Environmental Protection Agency (EPA), U.S. Department of Agriculture (USDA), local governments, environmental nonprofits and others. EPA Region 4 and the US Composting Council were developing model compost rules at this time and that model was considered in drafting the South Carolina regulation. EPA Region 4 and the US Composting Council were developing model compost rules at this time, which were considered in drafting the South Carolina regulation.

The revised regulation — which became effective June 27, 2014 — includes siting, operational, closure and financial responsibility standards for composting facilities as well as testing standards for finished compost. But the regulation is flexible enough to allow variances from regulatory requirements, provided the applicant can demonstrate that the proposed alternative is safe and effective. “The new regulation not only provides the guidelines for the safe and efficient management of organics that protects human health and the environment, but it also is designed to attract and support the composting industry,” explains Elizabeth Dieck, Deputy Director of DHEC.

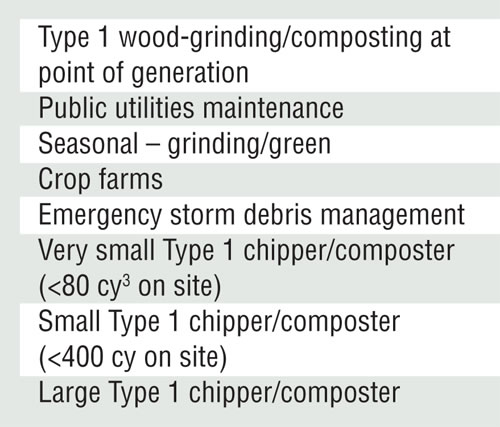

The regulation expands the list of materials that can be composted and clarifies guidelines for the management, mulching (grinding) and composting of land clearing debris and yard trimmings. It creates three facility types, based on three feedstock categories, with varying exemptions or conditions depending on the feedstock, end product and size or location of the facility (see snapshot in Table 1).

Feedstock Categories

The original regulation did not address feedstocks other than yard trimmings (known in the original regulation as “yard trash”) and land clearing debris. The revision expands the list of allowable feedstocks to include materials such as food waste, fats/oils/greases (FOG), unrecyclable paper, produce, biosolids and manure. It utilizes tiered permit requirements, depending on the feedstock, facility size, and whether or not the facility is located at the point of feedstock generation. Feedstock categories were designed with consideration to the risk of contamination from pathogens, trace metals, hazardous constituents or physical contaminants that are not compostable.

Category One feedstocks only include yard trimmings; leaves and grass clippings; land clearing debris; wood chips and sawdust; agricultural crop field residuals; and compostable yard trimmings bags.

Category Two feedstocks have a lower carbon-to-nitrogen ratio than Category One feedstocks, high moisture content and are more likely to contain pathogens, trace metals and physical contaminants. This category only includes the following source separated material: nonmeat food processing waste; produce and nonmeat food residuals from wholesale, retail or food service establishments; plate scrapings from food service establishments; certain manufactured compostable products and waste paper products; animal manure and material incidental to its collection; and certain residual organics from waste-to-energy conversion processes, e.g. anaerobic digestion.

Category Three feedstocks have properties that may require more intensive analysis and monitoring prior to being incorporated into the active composting area and approved for composting by DHEC on a case-by-case basis. Included are biosolids, industrial sludge, and drinking water treatment sludge; FOG; and animal-derived residuals except as specifically identified as a Category Two feedstock.

Mixed municipal solid waste (MSW) is a prohibited feedstock unless a facility can demonstrate safe and effective operations for a two-year period under authority of a RD&D permit.

Testing And Exemptions

Compost made by facilities that manage Type Two and Type Three feedstock must be tested on a frequency prescribed by the regulation.

Steps were taken during rule revision to provide exemptions from permitting or to reduce the regulatory requirements whenever possible. Exemptions were developed in hopes of promoting on-site composting at industrial and institutional locations and to encourage small-scale composting that would foster future development into larger, more complex operations.

The following activities are exempt from permitting: all backyard composting; on-site wood grinding; on-site composting of Category One feedstock; management of Category One feedstock in amounts less than 80 cubic yards; composting of Category Two feedstock in amounts less than five cubic yards; emergency storm debris management; on-site farming operations; community programs such as “Grinding of the Greens;” and participants in the USDA’s National Organic Program.

Conditional exemptions are provided to the following activities: management of Category One feedstock in amounts less than 400 cubic yards; management of Category Two feedstock in amounts less than 40 cubic yards; and management of Category Two feedstock generated and managed on site of commercial, industrial, or institutional properties in amounts of less than 400 cubic yards.

An example of a conditional exemption is a facility, e.g., college, manufacturing plant or restaurant, which is allowed to compost their Category One and Category Two feedstocks without a permit as long as they have less than 400 cubic yards of unfinished material on site at any time and maintain certain buffers. Up to 40 cubic yards of material that includes food waste may be composted at a location other than the point of generation, without a permit, provided the composter complies with the buffers and conditions of the conditional exemption. (This exemption would apply to community composting sites, urban farms and community gardens.)

Conditionally exempt activities must be performed in accordance with the following buffers: 200-foot buffer from residences, schools, day-care centers, churches, hospitals and parks; 100-foot buffer from drinking water wells; and 50-foot buffer from property lines.

Additionally, the regulation requires exempt composting activities to be performed so as to properly manage putrescibles and storm water as well as prevent fires.

With input from DHEC inspectors, the decision was made to exempt facilities using a system based on maximum allowable material at the site at any given time. This method allows inspectors to visit a site and determine compliance visually, avoiding the need to review historical throughput and annual production records.

Jana White manages the South Carolina DHEC Solid Waste Grants, Planning and Regulation Development Section. She has more than 20 years of experience in solid waste management, and provided oversight of the 2014 revision to the South Carolina composting .