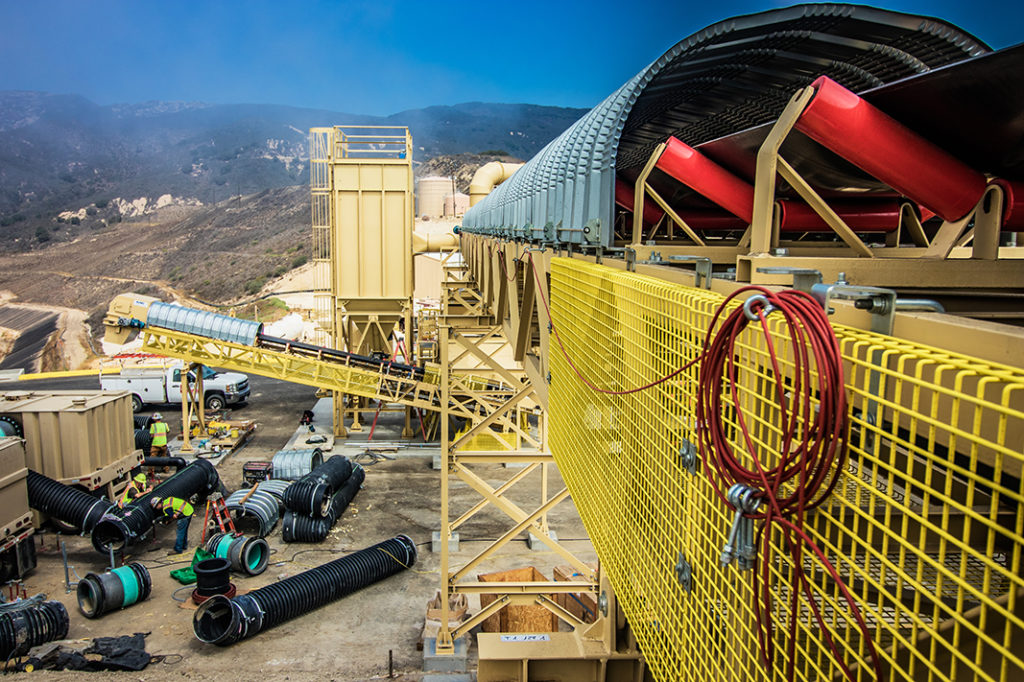

Top: Santa Barbara County’s new AD facility has a design capacity of 74,600 tons/year.

Nora Goldstein

The first scoop of sorted organics from the southern part of Santa Barbara County, California was loaded into a bunker at the county’s Anaerobic Digester Facility (ADF) in late August. The facility’s design capacity is 74,600 tons/year. The county selected a Bekon dry fermentation system. This is the first U.S. installation for Bekon, which is based in Germany.

The ADF is at the county’s Tajiguas Landfill in Santa Barbara, and is part of the ReSource Center that also includes a materials recovery facility (MRF) and a composting operation. The county owns the MRF and ADF and contracted with its developer, Mustang Renewable Power Ventures, to build and operate the facilities. Mustang contracts Bekon to operate the ADF, and MarBorg Industries, a solid waste services provider, operates the MRF. “Bekon has experience operating its dry fermentation facilities in Europe, and wanted to be involved in its first facility installed in the U.S.,” explains Carlyle Johnston, a member of the project team.

The Santa Barbara County Resource Recovery and Waste Management Division is one of several divisions within the Santa Barbara County Public Works Department, and is responsible for providing regional solid waste management services. Two franchised waste haulers service five zones in the unincorporated areas of the county, divided into the South County Areas and the North County Areas. MarBorg is the franchised hauler for the South County Areas. Waste Management is the franchised hauler for the North County Areas.

The ADF, MRF and composting operations at the Tajiguas Landfill process materials collected in the South County Areas. Some commercial generators and institutions in that region source separate their organics for collection. The residential sector uses a three-stream sort: trash, including food scraps; single-stream recyclables; and green waste. Households do not put separated food scraps in the green waste cart. “We have a very successful green waste recycling program that produces mulch used on avocado orchards in the region,” explains Johnston. “It costs the county about $45/ton to mulch the green waste. If we diverted it to the ADF, the cost would be over $150/ton to process it there.”

He adds that the South Coast of the county, which has over 150,000 residents, generates around 40,000 tons/year of green waste alone. “There are very large properties with lots of landscaped areas that generate material year round,” he says. Eventually, the county has the ability to consider a pilot project to commingle household food scraps with the green waste in the collection carts but that would come at an increased cost to customers.

Commingling the organics in the trash, sorting them out at the MRF, and processing them via anaerobic digestion enables the southern portion of Santa Barbara County to comply with California’s organics recycling law (SB 1383). Compliance with the law starts in 2022. “We had focused on this approach for organics coming out of the South County areas before SB 1383 was passed,” says Johnston.

The North County areas will be taking a different approach to organics management due to more limited processing opportunities. Details are being worked out, but will likely entail households commingling food scraps and green waste in the organics cart. “We anticipate doing a mix of things in terms of collection and processing,” he adds.

Facility Operations

The MRF has capacity to process around 180,000 tons/year of trash and commingled recyclables. Combined, the MRF and the ADF cost about $135 million; the county received a $4 million grant from CalRecycle for the ADF. Johnston says the combination of building adjacent to the landfill and being in an earthquake zone required a more engineered and expensive foundation.

The MSW fraction is tipped at the MRF where there is a MSW specific infeed processing train. A second infeed is used for curbside commingled recyclables. The MSW first goes through a shredder and size reducer, then a trommel that separates materials by size. The first fractions to be pulled out of the MSW are heavy, small items that are largely organic waste. All streams of materials are processed by a series of screens and optical sorters to pull out containers, plastics, and metals. Quality control staff pull out large organics from other streams being processed.

Aggregating the organics from the various streams makes up the fraction that is loaded into roll-off containers and transported to the tipping floor of the ADF. Once the material is loaded into the bunkers, ground green waste is added to improve the flow of the percolate (microorganism-rich liquid) through the mass. To “kick-start” the AD process, cow manure was added to the organics and ground green waste, along with some water.

The ADF has 16 bunkers (1) that are filled and emptied using a front-end loader (2). The first bunker was loaded in August (3). Photos by Lael Wageneck, Santa Barbara County Public Works Department.

The Santa Barbara Bekon facility has 16 concrete bunkers, and operates in a batch process. Each bunker is 23-feet wide, 17-feet high, and 100-feet deep. Once loaded, material remains for 28 days. The percolate drains to a tank and returns to the fermenting mass to keep it moist. The tank’s walls and floor are heated — using heat captured from the combined heat and power (CHP) engine — to maintain the percolate at an optimum temperature for biogas production. After 28 days, a bunker is unloaded (using a loader bucket); material is bulked up with ground green waste if needed, and then reloaded into the bunker for another 28 days of anaerobic digestion.

Currently, the system is operated at mesophilic temperatures (around 102°F). The Bekon system can be operated at thermophilic temperatures if desired, which could shorten the retention time and create capacity for processing more material. After the second 28-day cycle, digestate will be conveyed to the composting site. It will be mixed with ground green waste to provide structure in the piles (due to the high moisture content of the digestate) and set out in windrows for four to six weeks. After curing, the compost will pass through a densometric table with a shaker screen to remove rocks, plastic and film. “The compost derived from MSW can’t be used for row crops, but could be used on avocado and citrus orchards in the county, as well as on park and rangeland, and golf courses,” says Johnston.

The ADF has two 1.1 MW CHP engines. In addition, both the ADF and the MRF have rooftop solar panels. “Both facilities are self-sustainable energy-wise,” notes Johnston. “Any excess electricity is put on the grid — enough to power about 3,000 homes.”

With the bunkers newly loaded and the facility not operating at scale, it will be a few months before more is known about biogas and compost production. The MRF and ADF are expected to be certified by CalRecycle as a “high diversion” facility, meaning it diverts >75% of the organic waste from landfill disposal.