Mark A. King and Carla J. Hopkins

On June 27, 2019, Janet Mills, Governor of the State of Maine, signed into law, LD 719, “An Act Regarding Adult Use of Marijuana.” This law directed Maine’s newly developed Office of Marijuana Policy (OMP) to formally adopt rules regarding adult recreational use of marijuana (Villeneuve, 2019). Coupled with Maine’s existing Medical Use Marijuana Program, LD 719 resulted in great interest in the cultivation and sale of marijuana statewide.

To avert potential environmental impacts, Maine Department of Environmental Protection (MEDEP) solid waste staff met with staff from OMP to discuss waste management concerns that might be associated with this developing industry. During the meeting, it became apparent that there was not clear guidance regarding disposal of non-saleable marijuana products (stems, root balls, damaged/diseased leaves, buds and other marijuana-derived products). The only two approved disposal practices identified were landfilling and incineration, both of which are expensive options and require off-site transport to secure locations. Additionally, under OMP’s proposed rule, any product containing more than 0.3% Tetrahydrocannabinol (THC) would need to be transported by an authorized entity (i.e., licensed individuals, Drug Enforcement Agents, or other law enforcement personnel) or “rendered unusable” prior to leaving a marijuana facility (Maine Office of Marijuana Policy, 2019).

To meet the standard for being considered unusable, marijuana materials need to be ground and mixed at a 50:50 ratio with an authorized waste material, which includes: animal manures, food waste, and yard trimmings. Since all of the approved materials were currently authorized to be composted in Maine, it was decided to conduct a series of trials to determine if composting could manage marijuana residue so that THC levels could be reduced to less than 0.3% following 8 weeks of active composting.

Besides reducing THC levels, the ultimate goal of the project was to develop a marijuana waste management best practice guidance that would be cost-effective, environmentally sound and, ultimately, protective of public health. Composting, if successful, would offer that solution. During composting, organic ingredients, including soluble nutrients, are consumed through microbial activity and transformed into complex organic compounds that are resistant to breakdown, contain very low levels of biological activity and are resistant to leaching (Rynk et al., 1992).

Materials And Methods

Study Site

Between September 20, 2019 and November 13, 2019, a series of composting trials were held at the Rainbow Valley Farm located in Sidney, Maine. The site on the farm for the composting trials contains a small section of gravel pad, measuring 75-feet wide by 150-feet long (Figure 1). This area was chosen as it provided a durable work surface and somewhat remote location to help keep the operation private. All surface water draining from offsite enters a grassy swale located to the lower left of study area (Figure 1).

Figure 1. Rainbow Valley Farm. Study site is located in the lower right-hand section of photo adjacent to the Farm’s existing composting site (see orange circle). Image source: Google Earth

Pre-Composting Assessment and Preparation

Prior to initiating composting activities, an inventory of on-farm composting feedstocks was conducted to help determine the most appropriate materials to blend together for the compost mix. A proper mix requires an appropriate balance of carbon, nitrogen, water and unrestricted airflow to help initiate and sustain the composting process (Rynk et al., 1992). One advantage of using the Rainbow Valley Farm site was that it already had numerous available feedstocks in abundance, including: bedded horse manure, dairy manure and two types of waste animal feed (corn and hay silage). Additionally, since the farm was already successfully composting, we decided to use its farm blend— an equal mixture of the 2 manures and the silage mix — as it proved to be biologically active at the outset (achieving temperatures of approximately 135°F-140°F on the same day the pile is built). Sobel (1983) found similar temperature results while working on heat energy recovery using a wide range of animal manures. All of the marijuana provided for this study came from a stockpile that had been previously confiscated by our project partners at the Maine Drug Enforcement Agency (MDEA). It was transported to the study site the first day of pile construction by MDEA agents (Figure 2).

To measure actual biodegradation activity, we collected a one-gallon sized composite sample of the unmixed marijuana material to determine initial (pre-composting) THC levels. A Maine certified lab, Tested Labs, a Division of Nelson Analytical Labs, located in Kennebunk, Maine, was chosen to do the analysis. This lab agreed to run a standard cannabinoid panel for all samples. For purposes of this study, we focused on the following three analytes: THCA-A, Delta-8-THC and Delta-9-THC, which when summed together equaled “Total THC” levels.

Compost Pile Construction

On September 20, 2019, three replicate piles were constructed using a farm tractor equipped with a front-end loader and a separate tractor-mounted manure spreader. Initially, three pile bases were formed using the farm blend compost mix; each base measured approximately 8-feet diameter by 12-inches in thickness. Next, one cubic yard of marijuana (approximately 700 pounds) was mixed with two cubic yards of the farm blend using the manure spreader; the discharge was directed so that equal portions of this mix were applied to each of the pile bases. Mixing augmented materials blending while rendering the marijuana unusable.

We soon found, however, that the blending was complicated because we were unable to control the manure spreader’s discharge pattern. Initial mixing, even at the spreader’s slowest speed, resulted in broadcasting of the material beyond the borders of the pile bases, requiring manual recovery of the contents. However, even with the discharge issues, each base eventually received approximately one cubic yard of an equal mixture of farm blend and marijuana. Figure 3 shows the pile building process from initial compost mixing to manure spreader off-loading onto the bases.

Figure 3. Marijuana pre-mixing with farm blend and subsequent addition to compost piles: Marijuana being added to manure spreader (A); Farm blend being added on top of marijuana in manure spreader (B); Difficulty in managing manure spreader discharge (C); Resultant mixture laying on pile base (D)

Photos by Mark King

In addition to the pre-composting marijuana sample, composite samples of each of the pile mixtures were also taken. Finally, each pile was then covered with an additional two cubic yards of the farm blend to help retain heat, minimize odors, and serve as a barrier to wildlife. The final piles measured approximately 4-feet high by 8-feet in diameter or approximately 4 cubic yards in volume (Figure 4). It was important to build representative sized piles to insure enough mass to facilitate active composting. Additionally, piles needed to be large enough to minimize the potential for heat loss due to the increased surface to volume ratio that a smaller pile would experience (Themelis, 2005).

Figure 4. Final pile construction (piles numbered from left to right — #3, #2, and #1, respectively). Farm owner/operator Harland Bragg stands next to Pile #2.

Photo by Mark King

Throughout the 8-week study period, piles were turned on a weekly basis to ensure adequate mixing and optimal composting conditions.

Pile Monitoring and Composting Activity

Throughout the 8-week study period, pile temperatures were monitored daily (at both 12-inch and 36-inch depths) using a pair of Reotemp® analog thermometer probes (300 Series). One set was placed within each pile. In addition to temperature, daily observations were also recorded for odors, leachate, and scavenging animal activity.

Composite samples were collected on October 11, 2019 and again on November 13, 2019 to determine THC levels. A leachate sample was also obtained from Pile #3 on October 11, 2019. All samples were analyzed at Tested Labs.

Results And Discussion

Temperature Performance

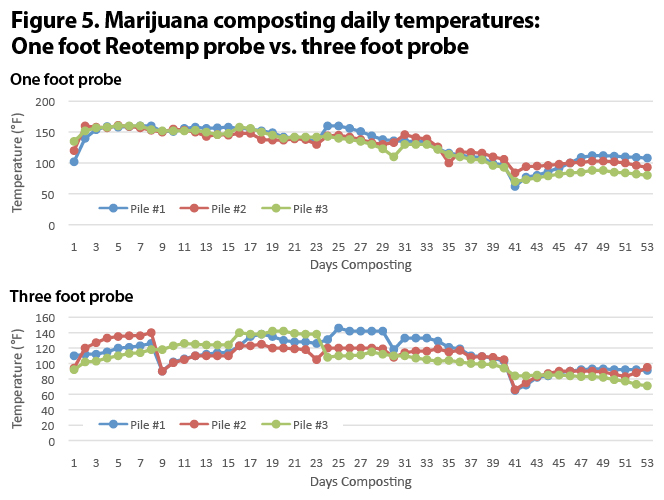

Figure 5 shows a comparison of the temperature performances of all three piles during the 8-week composting study. Temperature data collected for both the 1-foot and 3-foot depths showed a strong correlation between the individual performances of each pile. More importantly, temperatures at both depths for all three piles consistently stayed within optimal ranges (131°F to 150°F) for a significant portion of the 8-week study.

This temperature response validated the appropriateness of the original recipe as sustained temperatures at these levels ensures inactivation of weed seeds and destruction of any pathogenic organisms. Another great indicator of optimal pile conditions was demonstrated by how quickly each pile recovered following weekly turnings and significant rain events (Figure 5). In all cases, pile temperatures were able to recover within 24 hours of turning events.

This temperature response validated the appropriateness of the original recipe as sustained temperatures at these levels ensures inactivation of weed seeds and destruction of any pathogenic organisms. Another great indicator of optimal pile conditions was demonstrated by how quickly each pile recovered following weekly turnings and significant rain events (Figure 5). In all cases, pile temperatures were able to recover within 24 hours of turning events.

Physical Pile Changes Noted Throughout Study

Over the 8-week study period, the piles changed dramatically in size and shape. By the end of the study, each pile had noticeably reduced in volume to approximately half of its original size. This phenomenon has been noted in numerous previous studies (Tiquia and Tam (2000), Paredes et al. (2000) and Breitenbeck and Schellinger (2013)). In fact, Themelis and Kim (2002) quantified the relationship between decomposition and sustained temperatures in compost piles and found that at 50°C (122°F), it takes about 4 weeks for 50% of the original organic matter to be degraded.

Pile Sampling Events

Piles were excavated on October 11, 2019 (approximately halfway through the study) and November 13, 2019 (completion of the study) to inspect for any visible remnants of marijuana and to take composite samples to analyze for THC levels (Figure 6).

Figure 6. November 13, 2019 (completion of study) — excavated compost piles prior to composite sampling for THC levels

Photo by Mark King

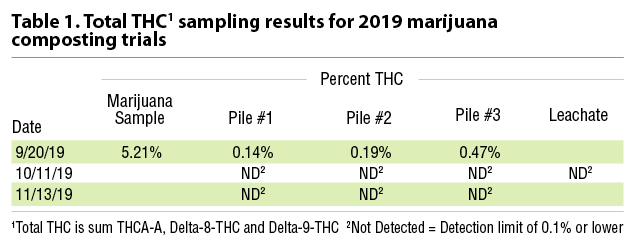

During each sampling event, a series of 25 composite subsamples (approximately 8 ounces each) were collected from each pile and homogenized in a 30-gallon trash bag. A single one-gallon sample was then collected to represent each pile. All collected samples were taken to Tested Labs for THC level determination. At the start of the study, approximately 700 pounds of marijuana were equally distributed over the three test piles. The lab analysis of the starting marijuana sample was recorded at 5.21% THC. Results of the pile samplings are summarized in Table 1.

Following the September 20th sampling, all subsequent sampling events failed to detect any remnant THC levels (lab detection limit was set at 0.1%). This positive finding demonstrated that composting had effectively degraded the THC levels in the tested marijuana to well below the regulatory target level of 0.3% THC.

Following the September 20th sampling, all subsequent sampling events failed to detect any remnant THC levels (lab detection limit was set at 0.1%). This positive finding demonstrated that composting had effectively degraded the THC levels in the tested marijuana to well below the regulatory target level of 0.3% THC.

Odors, Vectors and Leachate

No significant occurrences of odors were observed during the study. Throughout, only the distinctly “skunky” odor of the marijuana could be detected in the immediate vicinity of the compost piles. There were several leachate outbreaks due to significant rain events during the study. A test of leachate on October 11, 2019 failed to detect any THC in the leachate (reporting level was 0.1%).

Regarding vectors, there was a slight issue with resident turkeys actively foraging on composting study piles, presumably to scavenge the remaining corn fragments in the corn silage. Once the piles had been flipped several times, turkey activity diminished and no other vector activity was noted during the study period.

Conclusions

Although the scope and size of this series of trials were limited, the results nonetheless support use of composting as a tool to manage marijuana products and processing waste. Sampling events on both October 11, 2019 and November 13, 2019 confirmed this by failing to detect any remaining THC (0.1% detection level). This indicated that the microbial activity within the compost pile is likely adequate to successfully degrade the THC in marijuana.

Given the success of this study, it is highly likely that marijuana processing waste could be added to community-based composting operations with the expectation that any remaining THC could be adequately degraded to allow widespread, unregulated use of the final compost produced. The MEDEA rule requires that the marijuana waste cannot leave the site of generation until it has been rendered unusable by the approved methods. Thus, the feedstocks necessary to blend with the marijuana waste (50:50 ratio) prior to composting would have to be on-site, whether the facility chooses to compost on-site or deliver the materials to an off-site facility.

Mark A. King is an Organics Management Specialist in the Maine Department of Environmental Protection’s Division of Materials Management. Carla J. Hopkins is the Supervisor of the Residuals Management Unit in the Division of Materials Management.