About 150 WRRFs in the U.S. accept food waste hauled to their anaerobic digesters for energy recovery. The potential exists to expand this to the 1,200 WRRFs with AD.

Lauren Fillmore and Allison Deines

BioCycle September 2016

A hauler connects to FOG receiving station at City of Gresham, Oregon Water Resource Recovery Facility. Photo courtesy of City of Gresham WRRF

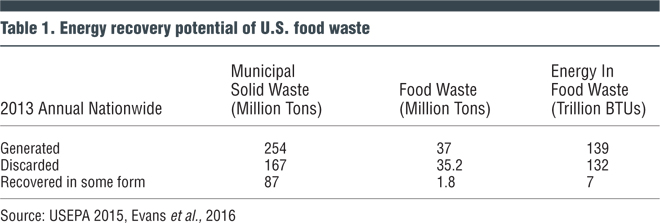

Another untapped resource in the U.S., domestic wastewater, contains total available energy of 851 trillion BTUs/year through chemical, heat and kinetic energy sources. Chemical energy in domestic wastewater is from constituents similar to food waste and comprises 20 percent (170 trillion BTUs/year) of the total energy (Tarallo 2014). Facilities originally built to solely treat wastewater are now being upgraded and operated to be water resource recovery facilities (WRRFs). In large part, this is possible through anaerobic digestion (AD) of wastewater solids to generate biogas that can replace fossil fuel to create power directly, to convert to steam or electric power, or for vehicle fuels.

Over a decade ago, WRRFs with anaerobic digesters recognized they could increase their production of biogas through codigestion of organic waste, largely comprised of food waste, with wastewater solids. The practice of codigestion is loosely defined as the addition of outside-the-facility-derived organic wastes directly to anaerobic sludge digesters, usually by hauling but occasionally by direct piping of food industry wastes to the digesters. The Gloversville-Johnstown (NY) acceptance of Fage yogurt whey waste is perhaps the most recognizable of the WRRFs that have direct pipes for getting food waste to digesters, however there are other examples.

The additional biogas produced through codigestion is attractive to WRRFs because biogas generates revenue as well as use for heat, power, electricity, or for sale as biomethane. These facilities often have the built infrastructure (anaerobic digesters with available capacity) and experienced operators. Approximately 150 WRRFs (Water Environment & Reuse Foundation (WE&RF), unpublished) in the U.S. already accept food waste hauled to their digesters for energy recovery. There is great nationwide potential to expand this number to the 1,200 (and growing) WRRFs with AD.

Sink Grinding And Sewer Conveyance

The Roadmap to Reduce U.S. Food Waste by 20 Percent (ReFED, 2016) identifies WRRFs with AD as a top food waste recycling solution, but missed the true potential by under counting WRRFs with AD that currently accept food waste in some form. The ReFED Roadmap limited its analysis to 40 facilities nationwide, although noted an additional opportunity for 34 more WRRFs. The Roadmap stated that since half of food waste comes from households, in-sink grinders paired with today’s pipe infrastructure was considered as part of its strategy for delivering material to WRRFs equipped with efficient treatment processes and AD energy capture. By focusing on kitchen grinders and a drain-and-pipe-based system, the ReFED Roadmap underestimates the opportunity for use of food waste discards for energy recovery and the positive synergy through an integrated food-water system achieved by accepting food waste directly at WRRF digesters.

A study by WE&RF (Parry, 2012) compared four food waste management alternatives, two of which were food waste through residential sink grinders and conveyance by sewers to the WRRF for AD, and energy recovery by hauling residential food waste directly to the WRRF with AD. The researchers found the greatest potential for energy recovery was through the hauled waste scenario, while the option with the lowest cost to the community was through grinders and sewer conveyance.

There are considerable community benefits to the grinder-sewer option: Improved neighborhood vector control and reduced truck traffic on residential streets are key benefits. However, there are educational and training objectives that must be achieved by the community to make this option successful. Residents cannot put grease or fat down the drain. Fat and grease turn to a hardened material similar to soap in the sewer environment (Ducoste, 2008), causing blockages leading to overflows. Yet, fat and grease wastes contain greater recoverable energy than most other types of food waste.

Theory and practice, as frequently the case, are not the same for food waste recovery through the grinder-sewer pathway. Why? While food waste from washing dishes and such has always been a part of domestic wastewater, conventional wastewater treatment plants were not designed to recover carbon from wastewater. Primary treatment — the point in the treatment train where much of the carbon in the wastewater can be diverted to anaerobic digesters at WRRFs — is designed to remove and divert only 30 percent of the oxygen demanding substances (largely carbon based) and about 58 percent of the carbon-containing solids.

The uncaptured solids and carbon continue to the secondary biological process where aeration is required to remove them. Aeration is expensive and consumes considerable electric power. Studies have shown that 50 percent (or more) of the electricity consumed at these plants is for the aeration process. (Crawford 2010).

Central Marin Sanitation Agency (CMSA) in San Rafael, California receives commercial food waste collected and preprocessed by Marin Sanitary Service, then taken to CMSA for codigestion. Photo courtesy of Marin Sanitary Service

WRRF And Codigestion Outlook

Leaders in the wastewater sector envision transformation of this service from treatment of waste to recovery of valuable resources, such as energy, nutrients and more. Renewed interest in AD by the nation’s WRRFs and substantial excess capacity that exists in AD facilities currently serving the sector enabled the practice of codigestion to spread nationwide. Leading WRRFs recognize that codigestion can boost energy recovery rates with minimal incremental transport and handling costs.

WRRFs are ideal environmental partners for pioneering food waste codigestion. As protectors of the environment and public health, however, they often adopt new practices slowly. They have a financial responsibility to their ratepayers to be judicious with their expenditures, even in light of future payback. This has limited the adoption of AD to about 10 percent of WRRFs, and codigestion of food waste to less than one-fifth of those with AD (Moss 2013).

While codigestion of food waste at WRRFs is a big part of the solution to recycling food waste for renewable energy, there are missing pieces. WE&RF researchers have identified barriers in selling distributed electric power generated from biogas to the grid, a lack of affordable financing and incentives for renewable energy projects, and simplistic utility decision making with unrealistic “project go” thresholds (Willis and Stone, 2012). Moving the energy and nutrient recovery of food waste forward in collaboration with WRRFs requires investment — although the return on that investment, both economic and in greater community benefits, is substantial.

Lauren Fillmore is a Senior Program Director at the Water Environment & Reuse Foundation, Alexandria, VA, where she manages their energy research portfolio since 2007. Allison Deines is the Director of Special projects at the Water Environment & Reuse Foundation, Alexandria, VA where she works with WRRFs to identify and fund new research projects.