Nora Goldstein

Top photos: Preprocessing food waste for codigestion at the Central Marin Sanitation Agency results in slurry (left) and residuals (right). Photos by Rashi Gupta

In 2016, California adopted Senate Bill 1383 (SB 1383) to reduce short-lived climate pollutants (greenhouse gases) like methane released from decomposing organic material in landfills. SB 1383 establishes specific targets and timelines to achieve reductions in the level of statewide disposal of organic waste at landfills. Municipal wastewater treatment plants (WWTPs) offer one avenue for the targeted organics diversion by accepting food waste and codigesting it with municipal solids. Through codigestion of diverted food waste in anaerobic digesters, municipal WWTPs could help achieve SB 1383 goals while producing and making beneficial use of biogas.

The California State Water Resources Control Board received a multi-purpose grant from the U.S. Environmental Protection Agency (EPA) to analyze codigestion capacity at municipal WWTPs in California and worked with Carollo Engineers, Inc. (Carollo) to complete the study and author the final report. The report, Co-Digestion Capacity In California, was released by the California Environmental Protection Agency (CalEPA) on August 24, 2020.

Drawing from a comprehensive statewide survey specifically developed for the study, the report describes the capacity of WWTPs to codigest food waste diverted from landfills, beneficially use the resulting biogas, and process biosolids with on-site infrastructure. Statewide costs and benefits associated with maximizing codigestion capacity are estimated, including potential greenhouse gas (GHG) emission reductions. Lastly, the report includes several case studies, which review factors that impede and facilitate codigestion in California and which comprise the basis for a screening process that utilities can use to guide decision-making. This article summarizes the report’s key findings.

The survey was sent to 223 permitted small, medium, and large WWTPs in the state by the California Association of Sanitation Agencies (CASA). Carollo received 99 responses, which covered a large percent of the total treatment plant capacity within California.

Big Picture

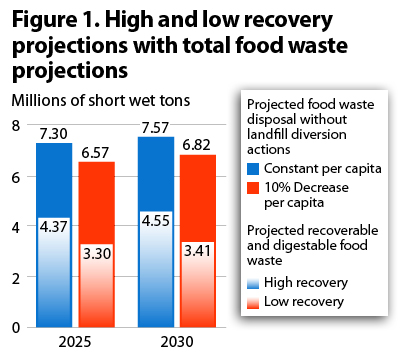

In 2017, an estimated 6.8 million short wet tons (short wet ton=2,000 lbs) of food waste were landfilled in California (CalRecycle data). Chapter 1 projects how much food waste may be available and suitable for codigestion in 2025 and 2030 in different regions of the state. In estimating the future amount and spatial distribution of disposed food waste, the analysis considered a range based on variables such as population growth, consumer behavior (constant or a 10% decrease in per capita generation), and technical feasibility of diverting digestible material (a high recovery of 60% or a low recovery of 50%).

To avoid overestimating the impact of food waste codigestion on GHG emission reductions, the report uses a conservative projection of 3.4 million short wet tons/year of food waste suitable for codigestion in 2030, i.e. the projection assumes people will generate less food waste and that only 50% of that food waste could be recovered for codigestion (Figure 1). The spatial distribution of this projection generally follows population centers within the state, with the largest quantities expected in the three most populous regions (Southern, Central and the Bay Area).

To avoid overestimating the impact of food waste codigestion on GHG emission reductions, the report uses a conservative projection of 3.4 million short wet tons/year of food waste suitable for codigestion in 2030, i.e. the projection assumes people will generate less food waste and that only 50% of that food waste could be recovered for codigestion (Figure 1). The spatial distribution of this projection generally follows population centers within the state, with the largest quantities expected in the three most populous regions (Southern, Central and the Bay Area).

Calculating Capacity

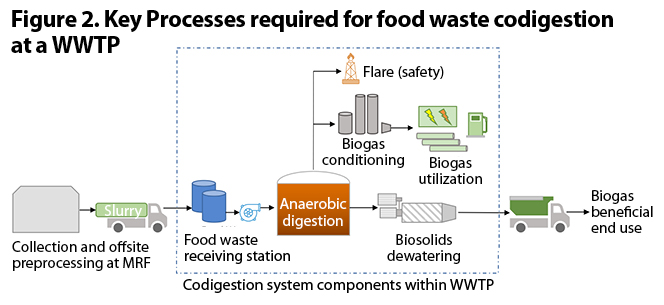

In Chapter 2, the report estimates the capacity of wastewater treatment facilities to accept and codigest food waste diverted from landfills, beneficially use the biogas, and dewater biosolids within existing on-site infrastructure. To accept food waste and beneficially use the by-products, a single facility needs to have capacity in these key components (Figure 2):

- Receiving station (suitable for food waste slurry)

- Anaerobic digestion

- Biosolids dewatering

- Biogas conditioning and utilization

- Biogas flare (required for safe operations)

For example, if a wastewater treatment facility has available digester volume to handle food waste but is unable to condition and utilize the resulting additional biogas, codigestion capacity is limited by the biogas systems.

For example, if a wastewater treatment facility has available digester volume to handle food waste but is unable to condition and utilize the resulting additional biogas, codigestion capacity is limited by the biogas systems.

Capacity estimates reflect the excess capacity available in these system components beyond what is needed for processing the residuals generated through wastewater treatment. A base assumption within the report is that the WWTPs would receive food waste slurry that is preprocessed off-site and hauled into the plant as a pumpable slurry. The food waste receiving station comprises the tanks and digester feed systems needed to accept food waste slurry and feed the digesters at the WWTP.

Central to the analysis is understanding anaerobic digestion capacity. Carollo determined the physical digestion capacity available at WWTPs based on the survey results, and compared that to the volume required to meet specific solids retention times (SRT) and volatile solids loading rates (VSLR). The load associated with projected sludge volume in 2030 and any external organic waste the plants already receive was subtracted from the available capacity to determine whether, and how much, excess capacity would be available for codigestion under the SRT and VSLR scenarios considered. Excess capacity was then converted and reported as short wet tons of diverted food waste based on a typical 30% total solids (TS) concentration for food waste. While excess capacity was reported as diverted food waste at 30% TS to illustrate the statewide impact for organics diversion, Carollo determined the required and excess capacity of the WWTP codigestion processes assuming that off-site processing would dilute the food waste into a 15% TS slurry.

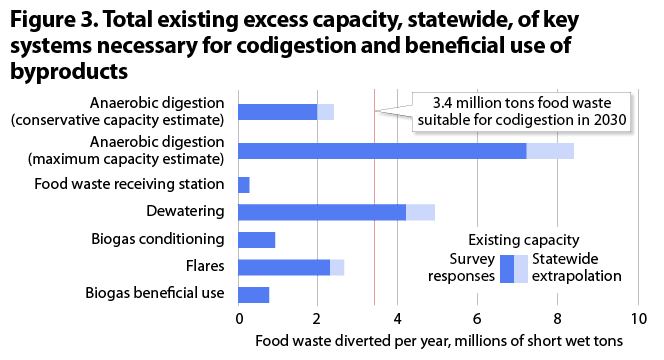

Figure 3 bookends estimated statewide anaerobic digestion capacity, which ranges from a conservative 2.4 million to a maximum of 8.6 million short wet tons of diverted food waste per year. These ranges reflect different assumptions regarding digester operating conditions, including system redundancy, varying retention times, and loading rates. The maximum digestion capacity estimate maintained a minimum 15-day SRT to meet 40 CFR Part 503 requirements for Class B pathogen reduction under mesophilic conditions. The conservative digestion capacity estimate was based on the WWTPs’ reported design SRTs, which were often greater than 15 days. Because of the increased digestibility of food waste compared to wastewater residuals, the report considered organic loading rates higher than typical values used for the mesophilic digestion of wastewater residuals only. All of the various operating scenarios considered are further described within the report and its appendices.

Figure 3 also shows the surveyed and extrapolated excess capacities of the other key systems noted in Figure 2. The facilities that responded to the survey comprised approximately 80% of the state’s total treatment design flow. To capture facilities that did not respond to the survey, additional capacity was extrapolated for large facilities known to have anaerobic digestion on-site. This extrapolation covered only large facilities and those processes typically sized relative to a plant’s influent flow. Of all the processes considered, anaerobic digestion and dewatering have the most aggregate excess capacity; food waste receiving stations and biogas conditioning and beneficial use systems have the least.

In short, there is likely more than enough existing excess digester capacity to accommodate the digestible and recoverable food waste projected to be available in 2030, if digesters are operated at maximum capacity. Even if operated more conservatively, the state’s existing digesters could handle 70% of this food waste projected in 2030. However, maximizing the use of that excess capacity will require expanding the capacities of other key system components.

For example, seven California WWTPs will soon have all the key components needed to codigest food waste, albeit in varying capacities that do not necessarily match their digester capacity. Together, the receiving and codigestion systems at just these seven facilities will have the excess capacity to handle 118,000 short wet tons of diverted food waste per year, which is less than 5% of digestible food waste projected by 2030. This value is based on the limiting capacity within the key processes required for the overall codigestion system. However, if the capacity of their limiting key components were increased to match the excess capacity of their digesters, just these seven facilities could handle at least 0.8 million short wet tons of diverted food waste, or nearly a quarter of digestible food waste projected by 2030.

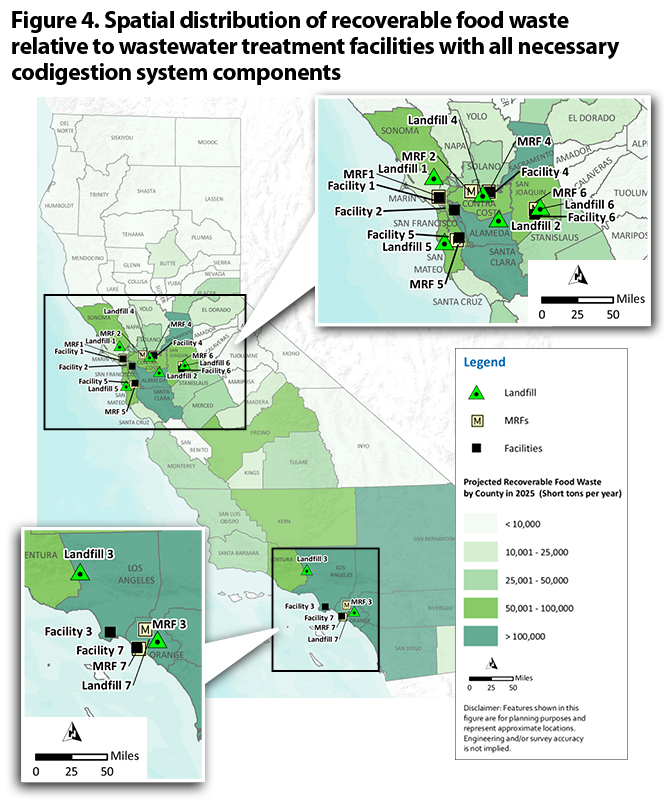

The report considered the spatial distribution of divertible food waste relative to the locations of these facilities. Figure 4 shows the amount of projected food waste within the state, with the darker green shades representing higher amounts of food waste. As indicated in this figure, the locations of these seven existing facilities correlates well to the locations in the state with the highest amount of projected food waste. This proximity makes these facilities attractive destinations for food waste diverted from landfills.

Net Positive Investment

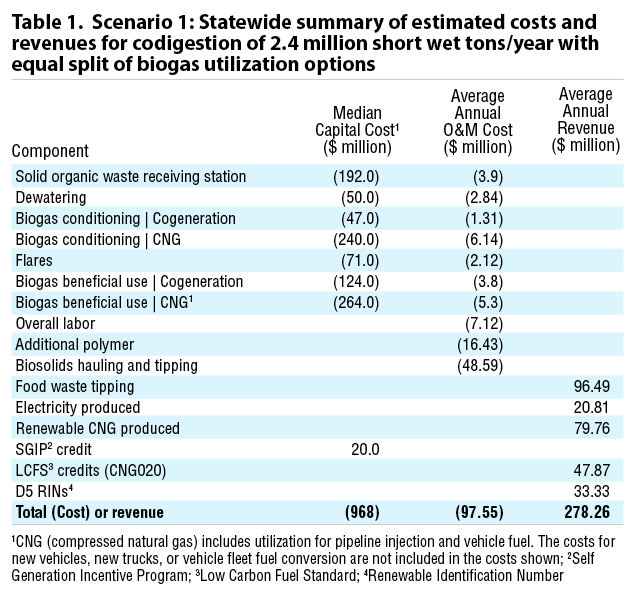

Chapter 3 estimates the statewide economic impact associated with fully utilizing the state’s existing, excess anaerobic digester capacity at WWTPs for the conservative and maximized digester capacity scenarios, Scenario 1 and 2 — and Tables 1 and 2 — respectively. This would require expanding the capacities of food waste receiving stations, biosolids dewatering systems, and biogas infrastructure (conditioning, beneficial use, and flares) to match the digester capacities for each scenario. Costs include infrastructure investments as well as annual operations and maintenance costs (O&M). Potential economic benefits include reduced energy costs, tipping fees, energy credits available at the time of the report — federal Renewable Fuel Standard’s D5 RINs and California’s Low Carbon Fuel Standard (LCFS) and Self-Generation Incentive Program — and biogas sales assuming an equal split across the state of biogas utilization for cogeneration and renewable compressed natural gas (CNG) production for pipeline injection and vehicle fuel (see Tables 1 and 2).

The estimated statewide capital investments to fully utilize existing digester capacity for food waste codigestion and beneficial use of by-products range between $900 million and $1.4 billion for Scenarios 1 and 2, respectively. Statewide, the annual net benefits (revenue less O&M) are estimated at $180 million to $255 million. The report notes that facility conditions, food waste quantities, biogas and biosolids management strategies, and the value of revenue sources (e.g. tipping fees, RIN and LCFS credits) would have significant impact on a specific project’s economics.

The estimated statewide capital investments to fully utilize existing digester capacity for food waste codigestion and beneficial use of by-products range between $900 million and $1.4 billion for Scenarios 1 and 2, respectively. Statewide, the annual net benefits (revenue less O&M) are estimated at $180 million to $255 million. The report notes that facility conditions, food waste quantities, biogas and biosolids management strategies, and the value of revenue sources (e.g. tipping fees, RIN and LCFS credits) would have significant impact on a specific project’s economics.

Several sensitivity analyses were conducted to illustrate the impacts of different biogas utilization options on the overall economics. These comparisons showed that the incentives associated with CNG, including the California-specific LCFS credits, heavily favor the CNG-based options and are critical to positive economic outcomes. Similarly, tipping fees paid to the WWTP for acceptance of food waste slurry comprise a significant portion of the total revenue and contribute to the net positive nature of the results. The specific assumptions regarding unit values for each of these cost components are documented within the report and its appendices.

Regulations can also impact the cost of codigestion projects within the state. Regulatory considerations regarding water quality, air quality, and solids management are summarized within the report. Associated uncertainty, potential future requirements, and permitting difficulties experienced by some utilities can present barriers that negatively impact codigestion and biogas utilization projects. Reducing regulatory hurdles and the financial burden on utilities seeking to implement codigestion are essential to large-scale feasibility. Grants, low interest loans, and public/private partnerships can all help with capital offset. One of the report’s appendices identifies several grant and loan programs that could support codigestion projects.

The investment estimates within the report focused on WWTP infrastructure only, and do not include costs for Materials Recovery Facilities (MRFs) and preprocessing infrastructure to separate organic from non-organic waste. Assessing whether the state’s existing MRFs could accept additional food waste, and whether the facilities possess the infrastructure needed to suitably process the food waste for codigestion at a WWTP was beyond the scope of this study. The report notes that to provide a holistic assessment of investments necessary to support the state’s organics diversion and GHG emission reduction goals, such an analysis should be completed.

GHG Emission Reduction Potential

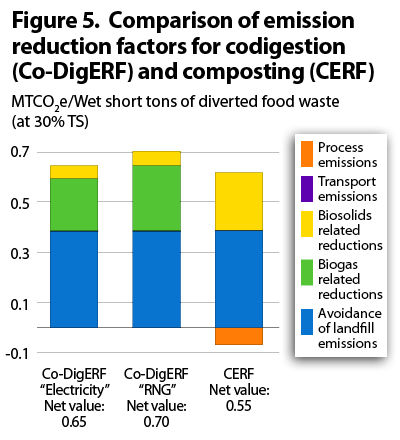

In Chapter 4, the report describes the potential GHG emission reductions associated with diverting food waste from landfills to WWTPs for codigestion. Investments to maximize the use of existing digester capacity statewide could reduce GHG emissions by 1.5 million metric tons of CO2-equivalent (MMTCO2e) to 2.4 MMTCO2e per year. This would be a significant portion of the state’s goal to reduce landfill emissions by 4 MMTCO2e in 2030.

Per short wet ton of codigested food waste, the avoided landfill emissions (blue column segments in Figure 5) are the largest single source of potential emission reductions. Beneficially using the additional biogas is another significant source of potential GHG emission reduction (green column segments in Figure 5). Some benefits of biosolids land application were included (decreased soil erosion and herbicide use), while other potential benefits (carbon sequestration, moisture retention, decrease in fertilizer use, etc.) were not included in the GHG emissions reduction analysis since research is needed to quantify the GHG mitigation benefits associated with these impacts. Even without these benefits, codigestion appears to have a slightly greater GHG reduction potential than composting because of lower process emissions (orange column segment in Figure 5). The compost values were calculated by the California Air Resources Board (CARB) in its 2017 Compost Emission Reduction Factor (CERF) Report and Carollo used the values CARB reported to compare to codigestion.

The terms noted in Figure 5 include:

The terms noted in Figure 5 include:

- Process Emissions: Includes preprocessing (slurrying), additional digester heating for food waste slurry, and additional dewatering energy (including polymer production and transport) for food waste.

- Transport Emissions: Transportation distances and emissions for codigestion are similar to those for composting (CERF Report). The report considered them to be functionally equivalent to those for landfilling for the purposes of estimating the emission factors. Therefore, the transportation emissions term was set to zero for the emissions calculations.

- Biosolids Related Reductions: Emission reduction associated with soil erosion decrease and decreased herbicide use from biosolids application.

- Biogas Related Reductions: Emission reduction associated with biogas used to generate electricity or to generate renewable natural gas (RNG) vehicle fuel.

- Avoidance of Landfill Emissions: Emission reduction associated with the avoidance of landfill methane emissions.

WWTPs And SB 1383 Implementation

With adequate resources, large and many medium-sized WWTPs can support SB 1383 implementation by codigesting food waste diverted from landfills and reducing methane emissions. Chapter 5 presents case studies from four medium-sized facilities, chosen to illustrate the potential benefits and challenges facing smaller agencies with fewer resources. Achieving California’s codigestion potential will not only require investing in infrastructure but also navigating complex regulatory, technological and institutional challenges, which can be particularly cumbersome for smaller facilities. Within an appendix, the report provides a screening process developed from the case studies and associated findings that utilities can use in decision-making related to codigestion.

Common factors found to facilitate codigestion at the plants highlighted within the case studies include:

- Legislative mandates for waste reduction and diversion from landfills

- Supportive partnerships with private waste management firms, power/gas utility providers, agency Boards or Councils, and the community at large

- Facility-specific planning efforts and feasibility studies

- Financing for projects

Chapter 6 describes case studies from two large facilities, with a focus on the impacts of codigestion on biogas and biosolids production. These case studies demonstrate that, despite challenges, codigestion benefits the environment and the bottom line of facilities by boosting biogas production and offsetting operating costs through tipping fees and renewable energy production. For example, if used on-site, biogas can significantly reduce energy costs. If used to offset petroleum-based transportation fuel, such biogas utilization can qualify for LCFS credit. The less a facility spends on energy and fuel, the more it can invest in improvements to protect water quality while moderating rate increases.

The bottom line of Co-Digestion Capacity In California’s findings is that by providing an avenue for food waste diversion through codigestion and producing renewable energy from resulting biogas, wastewater treatment plants can play a significant role in statewide methane emissions reduction — the driving objective of SB 1383. Access the report and the appendices.

BioCycle was greatly assisted with this article by Rashi Gupta, Vice President and Project Manager with Carollo Engineers, who has specialized in delivering sustainable solutions for biosolids management and wastewater treatment throughout her 17-year career.