The Ohio Environmental Protection Agency is seeking input on guidance it is developing to address storm water management at composting operations.

Marsha Johnston

BioCycle December 2014

Among best practices for food scraps management is situating the unloading/loading areas indoors or in a covered area.The U.S. Environmental Protection Agency, under its “Multi-Sector General Permit For Stormwater Discharges Associated With Industrial Activity,” regulates discharges of storm water from 29 different industrial sectors. The sectors group similar facilities by the nature of industrial activity, type of materials handled, and material management practices employed, and are based on the definition of “storm water discharge associated with industrial activity” (found at 40 CFR 122.26 (b)(14). Most sectors are defined by the North American Industrial Classification System (NAICS). The U.S. EPA has factsheets identifying specific activities and their potential resultant pollutants, and pollution prevention best management practices (BMPs). Permittees regularly use these factsheets to prepare the storm water pollution prevention plan required by the permit.

The problem, as previously reported in BioCycle (search biocycle.net archives under NAICS), is that the composting industry has no NAICS code. Consequently, says Angel Arroyo-Rodriguez, Environmental Planner & Sustainability Coordinator with the Ohio Environmental Protection Agency’s (OEPA) Office of Compliance Assistance & Pollution Prevention, composting is assigned to an industrial sector that is not a good fit and consequently does not provide appropriate detailed guidance. “A composting facility is usually assigned to Sector C, under the Chemical Fertilizers, but that doesn’t fit really well because it describes an industry that makes fertilizer,” he explains. “It doesn’t talk about the process of making compost. Or, if they are just grinding wood, they usually go to Sector A, Wood Products.”

Guidance For Composters

Composting facilities in Ohio are required to get Multi-Sector General Permits (MSGPs), and they often struggle with how to prepare the storm water pollution prevention plans required for the permit, adds Arroyo-Rodriguez. “They need guidance.” To address the situation, the OEPA’s Office of Compliance Assistance and Pollution Prevention, and its Divisions of Surface Water, and Materials and Waste Management, set up a workgroup. “We want to determine appropriate storm water management BMPs specifically for composting facilities so we are able to provide better compliance assistance, avoid or reduce the need for permitting, while using innovative solutions and the best regulatory approach,” explains Arroyo-Rodriguez. “The idea is to organize the guidance so it is similar to the U.S. EPA industrial sector factsheets for storm water management. A Composting Sector factsheet can clarify the regulatory framework for storm water and wastewater.”

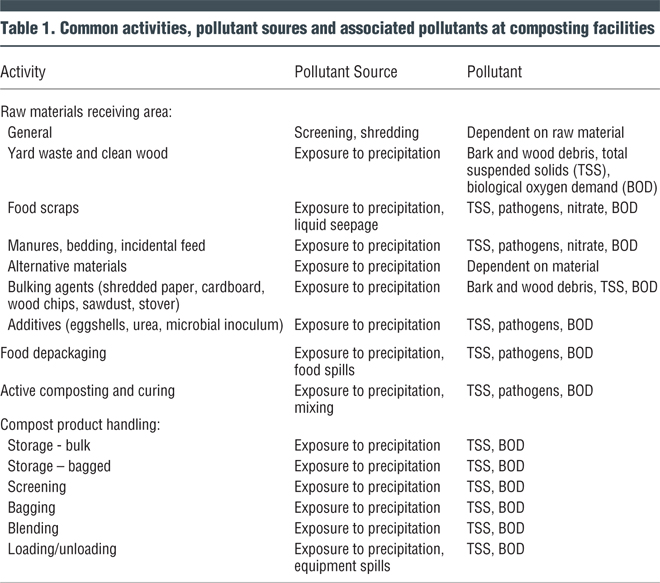

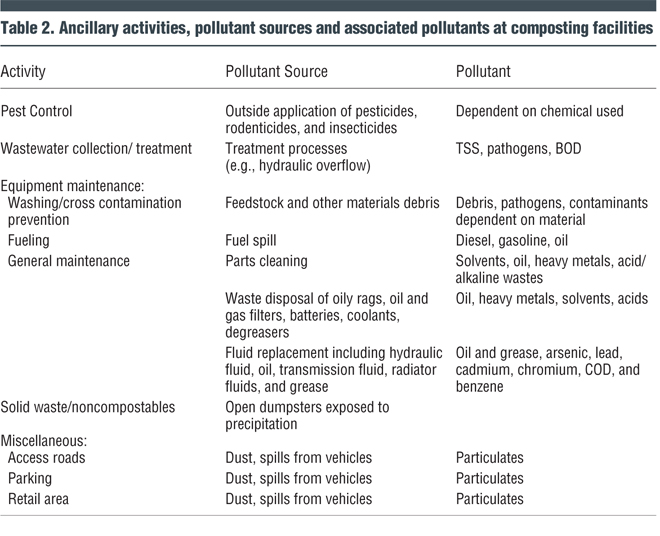

The workgroup, with input from other regulators and composters, is developing a comprehensive compost-specific checklist of activities, resultant pollutants and BMPs. Tables 1 and 2 list common activities, pollutant sources and associated pollutants at composting facilities and ancillary activities. These combine elements from the Chemical Fertilizer, Wood Products, Food Products, and Recycling industries MSGPs. The following is a sampling of the BMPs under consideration:

Raw Materials Receiving Area (General)

• Divert storm water around receiving areas with vegetated swales, and/or berms. A properly designed vegetated swale can also provide infiltration benefits.

• Locate receiving areas on stable, well-drained soils with slopes of 2 to 5 percent to prevent ponding and to convey storm water and leachate to treatment. Sloping should be limited to prevent erosion. Slopes should be stabilized.

• Line storage areas with crushed rock or gravel or porous pavement to promote infiltration, minimize discharge, and provide sediment and erosion control.

• Practice good housekeeping measures such as frequent removal of debris, bark, and wood waste. Cleanup methods may include mobile sweepers, scrapers, brow logs (log placed parallel to roadway), or scoops.

• Use sedimentation measures to control sediment from leaving storage area.

• Cover piles to prevent contact with storm water (use roofs, canopies, soils, sheds, etc.).

Yard Waste and Clean Wood

• Consolidate piles to minimize surface areas exposed to precipitation.

Food Scraps

• Situate loading/unloading areas indoors or in a covered area.

• Confine loading/unloading activities to designated areas outside drainage pathways and away from surface waters.

• Use a dead-end sump where materials could be directed.

• Avoid loading/unloading materials in the rain or provide cover or other protection for loading docks.

• Provide diversion berms, dikes or grassed swales around the perimeter of the area to limit run-on.

• Cover loading and unloading areas and perform these activities on an impervious pad to enable easy collection of spilled materials.

• Where liquid or powdered materials are transferred in bulk to/from truck or rail cars, ensure hose connection points at storage containers are inside containment areas, or drip pans are used in areas where spillage may occur which are not in a containment area.

Bulking Agents (shredded paper, cardboard, wood chips, sawdust, stover)

• Consolidate piles to minimize surface areas exposed to precipitation.

• Cover piles to prevent contact with storm water (use roofs, canopies, soils, sheds, etc.).

Food Depackaging

• Situate loading/unloading areas indoors or in a covered area.

• Confine loading/unloading activities to designated areas outside drainage pathways and away from surface waters.

• Cover loading and unloading areas and perform these activities on an impervious pad to enable easy collection of spilled materials.

Active Composting and Curing Areas

• Provide diversion berms, dikes or grassed swales around the perimeter of the area to limit run-on.

• In-vessel or contained methodologies are preferable.

• For windrows and piles, perform operations under roof, or cover to prevent precipitation from infiltrating into the piles.

Compost Product Handling, Storage (bulk), Storage (bagged)

• Provide diversion berms, dikes or grassed swales around the perimeter of the area to limit run-on.

Once the OEPA guidance is finalized, Arroyo-Rodriguez says it could be submitted to the U.S. EPA even without a NAICS code, using the Alternative Sector category that EPA has allowed. The workgroup is seeking input on its tables and BMPs. Arroyo-Rodriguez urges all interested parties to contact him at angel.arroyo-rodriguez@epa.ohio.gov. m

Marsha Johnston is a Contributing writer to BioCycle.