Craig Coker

Capital cost estimating for building, expanding or upgrading a composting facility varies in precision as a function of the extent of detailed design and construction bids. The main categories of capital costs to be estimated include site development, processing equipment (both stationary and mobile), and process monitoring equipment. In early facility planning, site development estimates will have an accuracy of +50%/-30%; following detailed design, accuracy will improve to +25%/-15%; after bid receipts, accuracy improves to +10%/-5%. To accommodate that varying accuracy, you should budget for contingency funds to cover any unforeseen items.

Site Development Costs

Site development costs are dependent on the chosen composting approach, as some methods take up more space than others. For example, turning windrows with a tractor-pulled turner requires dedicating space for the tractor whereas straddle turners take up less space; aerated static pile (ASP) systems take up even less. Evaluating composting approaches goes hand-in-hand with evaluating sites; if a larger site is possible, then it may be feasible to compost with less capital-intensive equipment, such as a tractor-pulled windrow turner. Of course, the converse is also true; if a site is small, then maximizing processing density (tons/day/acre of compost pad) with a compact composting approach makes sense.

In one example, a Washington state facility was composting in straddle-turned windrows on a 300-foot by 350-foot pad (2.4 acres). Using windrows, it was able to compost about 7,500 cubic yards (cy) on that pad. The facility decided to switch to extended ASP composting, and the capacity of that pad increased to 22,750 cy, a 3-fold increase.

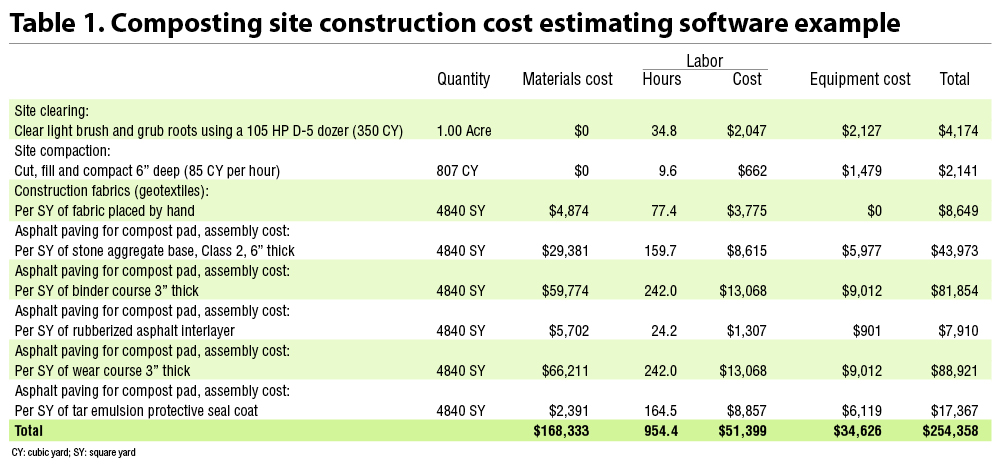

Site development costs can be estimated with construction estimating software. Because those programs are intended to be used by construction contractors preparing bids from detailed design drawings and specifications, they can be quite detailed. Table 1 shows the installation of an asphalt composting pad. In this example, the software was used to develop a line-by-line estimate for building a one-acre asphalt composting pad in Pittsburgh, PA. These software packages can be tailored to local conditions; in this case, national average cost adjustment factors for zip code 15201 included: 5% for materials, +20% for labor and -2% for equipment.

Source: US Composting Council

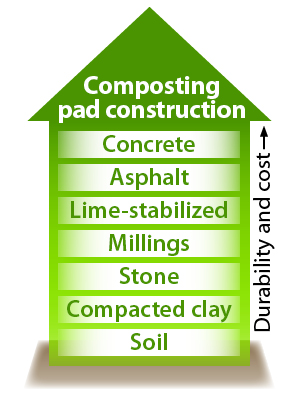

Compost pad construction is normally one of the larger cost elements in site development. “Composting pad construction” figure illustrates the relative costs of various materials used in compost pad construction.

Processing Equipment

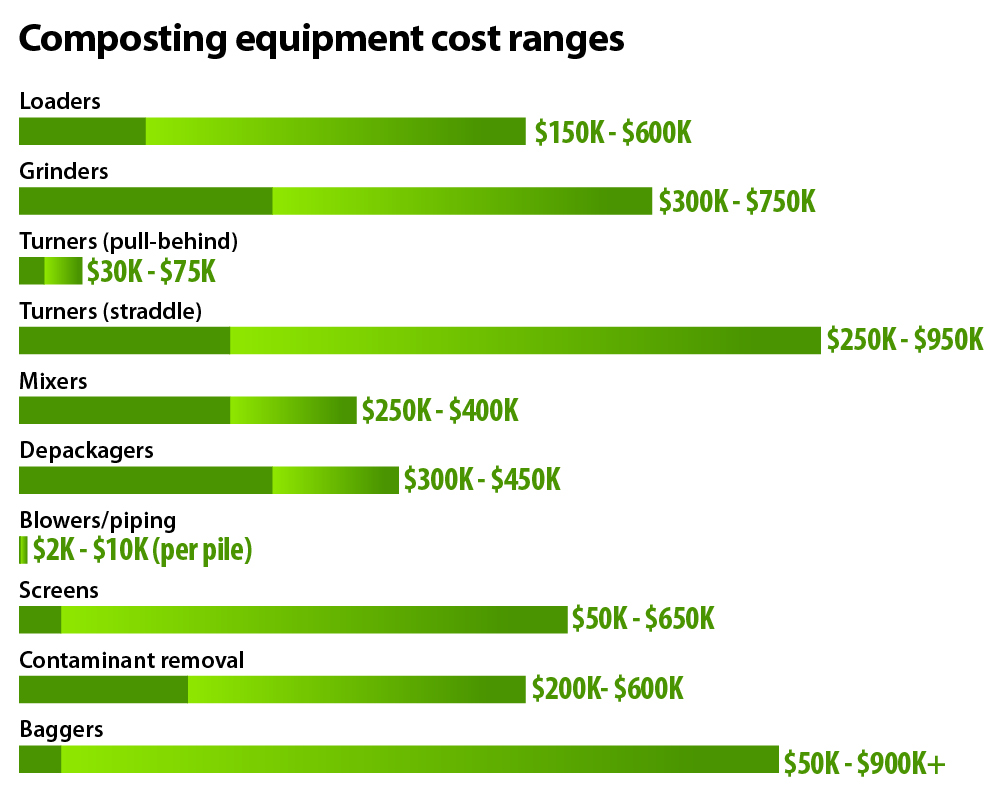

Processing equipment includes front-end loaders, grinders, turners, mixers, depackagers, blowers and piping, screens, contaminant removal and bagging. Multiple companies in the U.S. offer various types of equipment and most exhibit their wares at composting and solid waste trade shows around the country. Equipment costs vary by size, capacity and technological sophistication. Equipment can be purchased, or, in many cases, leased for several years. If leased, those costs get reflected in your operating costs, not your capital costs. Typical cost ranges for various types are shown in figure “.

Most of this equipment is available in the used equipment market where capital costs are much less. However operating costs are higher, with larger expenditures due to wear in components.

Most of this equipment is available in the used equipment market where capital costs are much less. However operating costs are higher, with larger expenditures due to wear in components.

Process monitoring equipment will include the basic essentials such as a 36-inch dial-face temperature probe ($150-$200) and an iPad ($750-$1,000). More sophisticated monitoring systems include wireless temperature probes ($2,000+) and Supervisory Control and Data Acquisition (SCADA) computer interfaces. Many composting facilities have a weather station to record wind speed and direction and rainfall amounts ($700 – $2,000) and a small on-site laboratory for measuring bulk density and free air space, microwave measurement of moisture content, pH tests, and the like.Process Monitoring

Craig Coker is a Senior Editor at BioCycle and CEO of Coker Composting & Consulting near Roanoke, VA.