Experience in 2015 demonstrated that composting can be a viable carcass disposal option for large avian flu outbreaks, with applicability for all types of poultry operations.

Gary Flory and Bob Peer

BioCycle January 2016

Photo ©2007 Gary Flory

The 2015 outbreak of Highly Pathogenic Avian Influenza (HPAI) was the worst animal disease catastrophe in United States history and it illustrates the enormous economic impact of foreign animal diseases. The HPAI virus originated in Asia and Europe where there were detections in 2014. Waterfowl migrated from their Asian and European wintering sites to their breeding sites in northern Asia. During the 2014 fall migration infected birds migrated to Canada where they infected poultry in British Columbia. As the migration continued south, the disease spread into the U.S. when it was first detected in Washington State in a captive-reared gyrfalcon on December 6, 2014.

Between December 19, 2014 and June 17, 2015, 219 detections of HPAI were reported across the country resulting in the death — either directly from the virus or in an effort to prevent the spread of the disease — of nearly 50 million birds. For U.S. consumers, this means that turkey prices are at record highs and the price of eggs has more than doubled.

The total cost of the outbreak extends well beyond the cost of destroying and disposing of the birds and includes lost market opportunities from trade restrictions. Eighteen countries have banned U.S. poultry products including Russia, China, South Korea and Thailand. Thirty-eight countries have instituted regional restrictions including Canada, Mexico, Japan, Singapore and the European Union. Recent estimates put the total economic impact of the outbreak at $3.3 billion (U.S.).

Air curtain destructors that incinerate poultry carcasses (left) and landfill disposal (right) are more traditional, but less environmental, management practices utilized in past disease outbreaks. Photos ©2007 Gary Flory

Carcass Management — Previous Outbreaks

In 1983, an outbreak of low pathogenic avian influenza in Virginia cost poultry farmers and the industry $40 million and resulted in the disposal of 5,700 tons of poultry carcasses. Approximately 88 percent of the carcasses were disposed in on-site burial trenches with the remaining 655 tons disposed at local landfills.

Eighteen years later, Virginia experienced an even larger avian influenza outbreak affecting 197 farms and a total of 4.7 million birds. At the time of this outbreak, attitudes towards environmental considerations were shifting as had the regulatory framework. Disposal in burial pits was no longer acceptable due to environmental and property value concerns. As a result, responders struggled daily to find ways to dispose of the poultry carcass being generated by the disease eradication effort. By the end of the outbreak, Virginia had used burial, incineration, landfilling and controlled processing to manage poultry carcasses. Although both composting in Ag-Bags (essentially silage bags fitted with forced aeration) and in-house composting were used on several farms, the methods were unsuccessful as executed.

Composting for disease response was first successfully implemented during an avian influenza outbreak in chickens in Delaware in 2004. In fall of 2004, researchers in Virginia initiated a demonstration project to evaluate the effectiveness of in-house composting on turkeys. Based on the results of this work, composting was used to control outbreaks of avian influenza in West Virginia and Virginia in 2007. Success during these outbreaks resulted in composting becoming a key carcass disposal tool during the 2015 HPAI outbreak.

Carcass Disposal — 2015 HPAI Outbreak

The first reported case of HPAI in the U.S. was on December 19, 2014 in a backyard flock in Oregon. Subsequent cases occurred in backyard flocks in Washington and Idaho. The first commercial poultry farm to test positive to HPAI was in California on January 23, 2015. The operation housed 134,400 turkeys and again highlighted the importance of poultry carcass management. The U.S. Department of Agriculture’s Animal, Plant, Health Inspection Services (USDA-APHIS) provided technical assistance to help determine the most appropriate carcass disposal method for this farm. In-house composting was chosen as the most biosecure and environmentally sound carcass disposal method. This was the beginning of an effort by USDA-APHIS to support state Departments of Agriculture with technical support and by coordinating carcass disposal at a national level.

Lori Miller, a Senior Staff Officer with USDA-APHIS, serves as the national coordinator for carcass disposal issues. As the outbreak shifted from the West Coast to the Midwest, the number of infected premises exploded and effective carcass disposal became a significant challenge to state Incident Management Teams (IMTs). To respond to this challenge, Miller drew upon the expertise of a group of individuals who have been meeting since 2005 to plan a series of successful conferences on mortality management — the most recent was the 5th International Symposium on Animal Mortality Management (held Sept. 28-Oct.1, 2015).

Members of this group have been working to advance the science and practice of animal mortality management for more than two decades. The group includes experts from Virginia and Delaware, the Maine Compost Team, Cornell Waste Management Institute, Canadian Food Inspection Agency and many other organizations. USDA-APHIS used these individuals as Subject Matter Experts (SMEs) to oversee carcass disposal activities. At the heart of the outbreak, there were about a dozen SMEs overseeing composting activities across the country. Since most of these SMEs were employed by universities or state agricultural or environmental agencies, they were deployed as independent contractors. Under this unique arrangement, SMEs took leave from their employers to respond to the incident as USDA-APHIS contractors.

Stretching The Science And Art Of Composting

Composting in response to a highly contagious animal disease is unlike composting in any other setting. Applying the rules and formulas found in most composting guides would result in immediate failure. The sheer volume of animal carcasses generated on a single farm can be overwhelming to the disease eradication effort. A single Midwestern turkey farm housing over 300,000 32-pound birds generated over 9 million pounds of infected poultry carcasses. Using a standard Carbon:Nitrogen ratio of 25:1 would be impractical and extraordinarily expensive. Because infected poultry farms are quarantined, all vehicles entering or exiting the farm must be thoroughly cleaned and disinfected. The process is time consuming and expensive. Therefore, composting in this environment requires the reduction of the C:N ratio to near the very limits of failure.

Any commercial composting operation knows the importance of maintaining consistent feedstocks. During an HPAI outbreak this is not an option. For biosecurity reasons, on-farm resources like poultry litter, clean wood shavings, corn stover, etc. are used first. Additional carbon resources are provided based on availability and proximity to the infected farm. Carbon materials will vary from farm to farm and may include wood chips, sawdust, corn stover, sunflower hulls, used bedding material or any other locally available carbon resource.

Thorough blending and shredding of compost mixes produces a homogeneous material with good carbon to nitrogen contact. In a disease environment, however, processes that could potentially aerosolize virus particles are minimized. Shredding of carcasses, for example, is avoided and mixing is minimized.

Moisture management is also different than in the typical composting environment. Assessing the ultimate moisture of the windrows is more challenging when they are built with whole birds. Market weight turkeys may weigh 40 pounds or more. Although 85 percent of the turkey is water, that moisture will not be released until the composting process begins. Underestimating the volume of the decomposition fluids can result in significant releases of leachate from the windrows. Additionally, when firefighting foam is used for humane depopulation of the poultry flock, as much as 10,000 gallons of additional water is added to each house and becomes part of the composting mix. As a result, additional water is rarely needed.

These and many other differences between routine composting and composting in response to an infectious animal disease require the consistent application of principles proven to be effective under emergency conditions.

Successful Composting During Outbreak

Early in the outbreak, SMEs were deployed across the country to coordinate on-farm composting activities without a formal communication process among them. Due to existing relationships, SMEs communicated individually to draw upon each other’s expertise. Midway through the outbreak, however, it became clear that a more formal communication mechanism was needed. Bobby Clark, a SME from Virginia, suggested a weekly conference call to achieve more consistency among deployed SMEs. These weekly conference calls continue today and the participants are considered the USDA-APHIS’ HPAI Composting Technical Committee. To help achieve consistency in the application of the composting method during HPAI outbreaks, this group recently released a national composting protocol titled HPAI Outbreak 2014–2015 Mortality Composting Protocol for Avian Influenza Infected Flocks (live link in online version of this article).

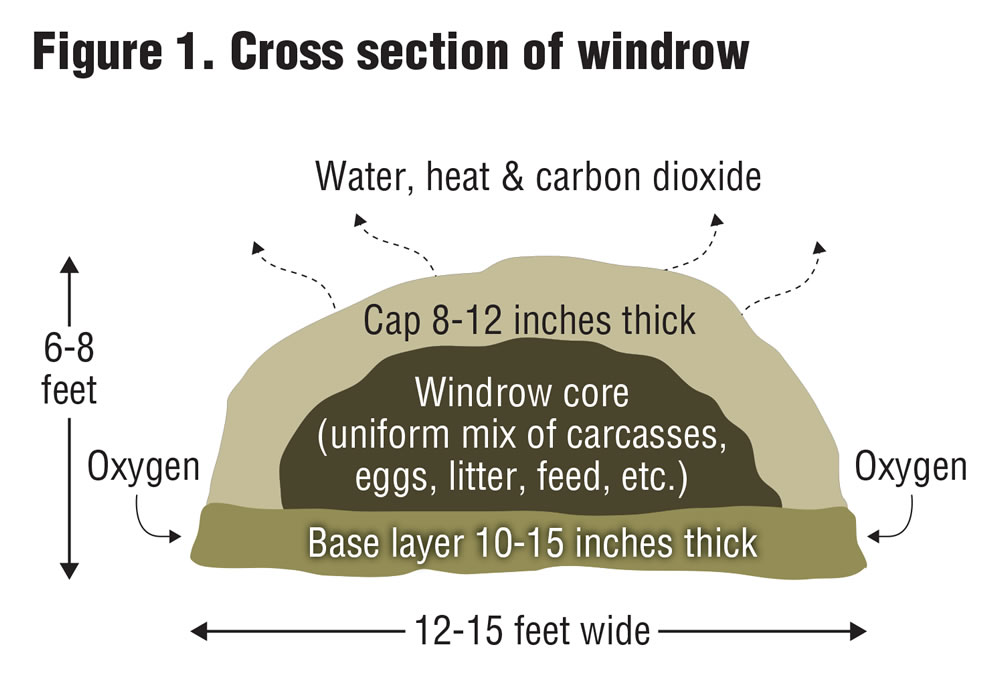

The collective experience of the HPAI Composting Technical Committee has determined that there are five key elements to effective application of composting during an HPAI outbreak. These elements can be visualized in a cross section of a windrow (Figure 1) and are summarized below:

• Windrows (typically 6 to 8 feet high and 12 to 15 feet wide) are constructed on an adequate and uniform base layer (10 to 15 inches thick) of a sufficiently porous and absorbent carbon material.

• The base layer and windrow are not compacted with equipment.

• Good carcass to carbon contact is ensured by creating a core with a minimum 1:1 mix, by volume, of carcasses, carbon, and other infected material (manure, egg shells, feed, etc.). Do Not Grind/Crush/Macerate The Carcasses During Construction!

• Windrows should be constructed to ensure adequate distribution of moisture throughout; the windrows are capped with carbon material (8 to 12 inches thick) to ensure that no carcasses are exposed and to minimize odor.

• Windrow dimensions, including the base and cap, may be reduced for smaller carcasses.

Composting Solution

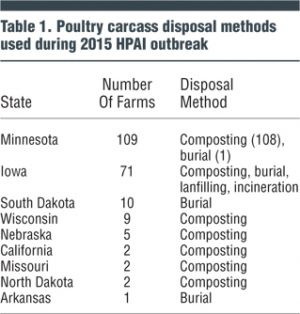

The Highly Pathogenic Avian Influenza Outbreak of 2015 saw the evolution of composting — either inside or outside the poultry barns — from a novel new disposal method to the primary disposal option for avian influenza. Although burial, incineration and landfilling were all used during the 2015 outbreak, composting was used on over 90 percent of the commercial poultry operations (Table 1). This experience demonstrated that composting can be a viable carcass disposal option for large outbreaks and that it has applicability for all types of poultry operations, from broilers and broiler breeders, to cage layers, to large turkeys and turkey breeder flocks. Additionally, this outbreak spawned a new model for harnessing widely distributed expertise and led to the creation of a mortality composting protocol that will be invaluable for future HPAI outbreaks.

Gary Flory is the Agricultural Program Manager for the Virginia Department of Environmental Quality and an independent global consultant, trainer and speaker in the areas of foreign animal disease response, counter-agroterrorism, One-Health, and animal carcass disposal. Robert Peer is the Agricultural Program Coordinator for the Virginia Department of Environmental Quality and composting Subject Matter Expert and consultant on animal carcass disposal.