Monroe Correctional Facility in Washington State uses low cost options — vermicomposting, fermentation and black solider flies — to process food scraps.

Nick Hacheney and Sally Brown

BioCycle October 2017

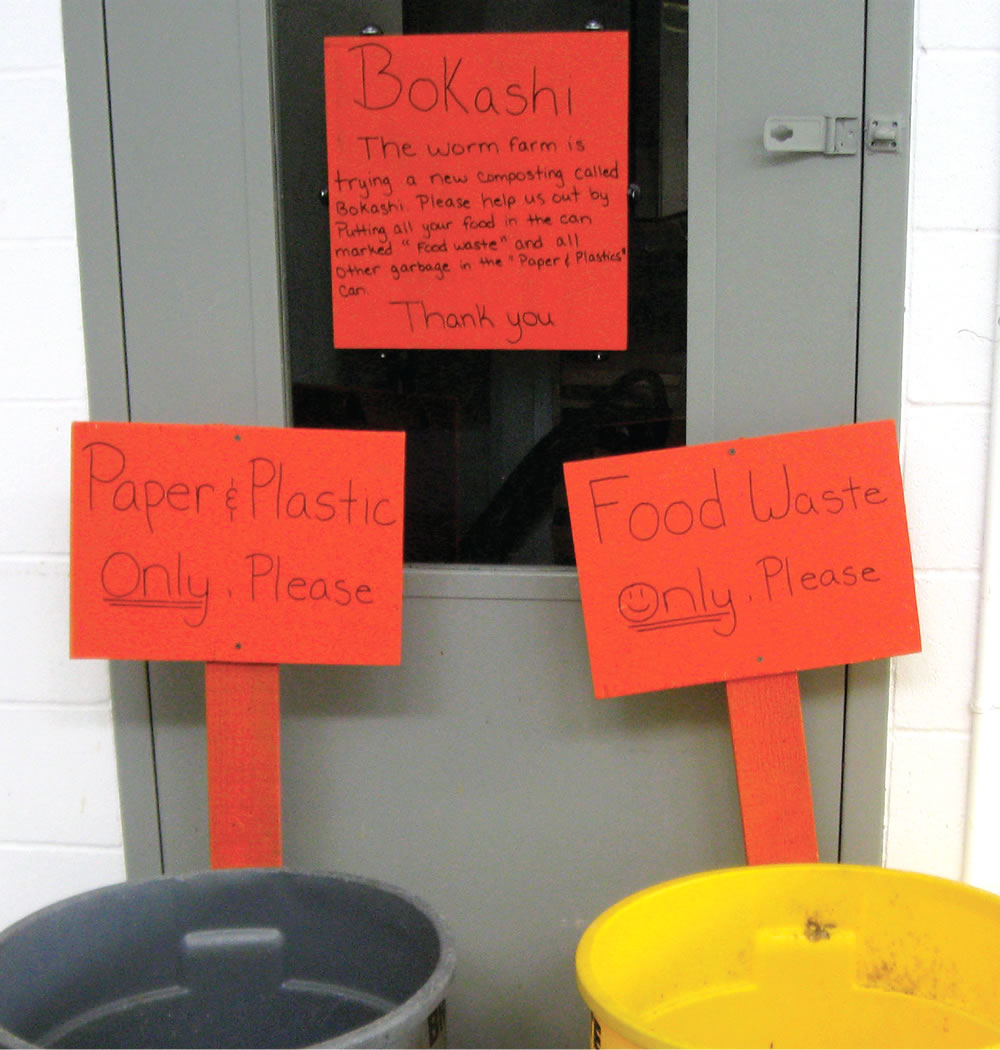

Initially, only vegetative food scraps could be collected for vermicomposting due to the worms’ limited diet. Food scraps collection station (above)

Photo courtesy of Monroe Correctional Facility

More and more discussions are centering on the appropriate way to divert food scraps from landfills. In many municipalities, this is often accomplished by cocollection of food scraps and yard trimmings, which can fit well into a preexisting program for yard trimmings. Existing composting operations can be adapted to handle the additional feedstock.

However, in certain cases, this existing model may not be appropriate. In areas or countries without centralized diversion, other alternatives to treating food scraps may be considered. Three of these alternatives — vermicomposting, Bokashi fermentation, and black soldier flies — may be appropriate in certain cases. The Monroe Correctional Facility in Monroe, Washington has experimented with all three of these options. Monroe houses 2,400 male inmates. The facility has access to commercial food scraps collection and composting. However a built in labor force with an active interest in diversion and a desire to reduce costs were sufficient motivations to try these alternatives. Nick Hacheney, an inmate at the facility and coauthor of this article, has been the lead for much of this work.

Vermicomposting

At the Monroe facility, the first alternative to traditional composting was stabilization with worms or vermicomposting. The facility had food scraps to work with and no high carbon woody type material to mix in as amendment. It opted for stabilization with worms as this could be done with very little capital investment and in a small area over a relatively short time frame. Vermicomposting is also a well-established process with extensive guidance available online.

The primary difference between conventional composting and vermicomposting stems from the fact that the process relies on the worms to eat the food scraps rather than bacteria in a conventional composting pile. The worms have different eating habits and preferences than the bacteria. These preferences are much narrower than the bacteria, hence the feedstocks suitable for vermicomposting are much more limited than what can be put in a standard windrow composting pile. Worms will readily eat fruit and vegetable scraps with the exception of citrus. However meats, dairy and fats are typically verboten.

Worms are also sensitive about the size of their food. If materials are too large, they can’t eat them, so the food scraps must be preprocessed to make them small enough for worms to eat directly. Like composting bacteria, the worms are aerobic, meaning that their bins have to have a good oxygen supply. Also like composting bacteria, they require sufficient moisture.

Finally, the end product of a vermicomposting operation is technically not compost, but worm manure. Worm manure, referred to as worm castings or vermicompost, is a highly desirable amendment for soils and can typically be sold for much higher prices than conventional compost. It is also possible to run this type of program as a worm breeding operation. Worms for composting can also be sold, offering the potential for a value added operation.

At Monroe Correctional, the vermicomposting program started in 2010 with 200 worms (Eisenia Fetida) and three breeding bins made in-house from donated wood. The program grew over several months but no protocols were established for how to manage the bins and use the finished product. As a result, the bins were not maintained properly and became odorous. The facility then appointed an inmate to come up with a best practices model and institute it.

The initial focus was to increase the worm population so there would be sufficient worms to process 10,000 pounds of food scraps per month. Using a text by Eric Wilson (Worm Farm Management: Practices, Principles and Procedures), beds were fed to maximum capacity and then allowed to breed (without feeding) for two weeks. The contents were then split into two bins and the same process was carried out. This approach was used to breed worms rather than immediately develop capacity for food scraps. When a sufficient population of worms was achieved, they were deployed to stacking totes with moist shredded waste paper and a layer of processed food scraps. Each bin was allowed to sit for 21 days at which point adults were removed, and bedding and eggs were put into a breeding bin. This enabled the operation to increase to 5 million worms in 2.4 years.

The takeaway for the inmates and staff is that it’s possible to develop a vermicomposting operation with very low start up costs and limited space. It does require dedicated staff and separation and shredding of the worm food. The other point is that if sufficient control over the conditions in the worm bin and the feeding are not maintained, the operation can go south. Basic parameters include a pH between 5-7, temperature (for rapid processing) between 60° to 80°F, and moisture between 60 and 85 percent. This has proven to be a well-run program and has expanded to other facilities within the Washington State Correctional System (see video: “Six Million Worms … and Counting”).

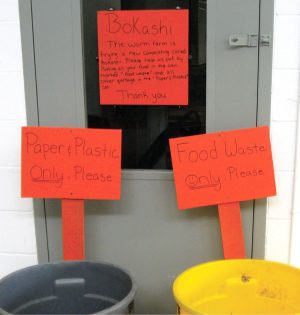

Adding a Bokashi fermentation pretreatment step enabled all types of food scraps to be managed on-site.

Photo courtesy of Monroe Correctional Facility

Pretreatment With Bokashi

Nick Hacheney and the others running the vermicomposting program were frustrated that the limitations to the worms’ diet also limited the amount of food scraps that could be treated on-site to about 6,200 lbs/month. Scoping around online, they decided that pretreating a wider range of food scraps, including meats, dairy and fats, using the Bokashi fermentation method would be a way to make these feedstocks suitable for the worms’ diet. Bokashi is a proprietary method that requires purchase of specialized microbes to ferment wastes. The wastes, in this case food scraps, are compressed with alternating layers of the Bokashi “bran” that has been inoculated with these specialized microbes.

Typically this “bran” is purchased, however it also can be made using select ingredients and a purchased microbial innoculum. The material sits and reduces in volume over time. Water is released. At the end of the requisite period, the fermented wastes are suitable for further treatment including vermicomposting, burial in soil, or conventional composting. The finished Bokashi product is not a finished product, but rather one that is ready for the next step. The water that is released has some value as it can be high in nutrients and microbial innocula.

At the Monroe facility, pretreating food waste, including meat, dairy and fats, using the traditional Bokashi method was sufficient to enable the worms to finish the job. With their enhanced diet, the time the worms required to process the food scraps increased but there were no other negative effects. The final product remained consistent and the health and breeding of the worms were not impacted. The inmates made their own “bran” using the purchased innocula. Their initial recipe was 1 cup of bran to 10 gallons of food scraps, but that was insufficient. The final rate used was 1 cup of bran to 4 gallons of food scraps. The calculated cost of homemade bran was $0.06 per cup. Total time required to make the bran was 2 weeks “cooking” and one week drying. Liquid from the treated food scraps was used to moisten the worm bin, added directly to gardens, or combined with grass clippings.

Fermented food scraps are added to the vermicomposting bins (below right) for the worms to “finish the job.”

on-site. Photo courtesy of Monroe Correctional Facility

Including the initial trial, the Bokashi method in combination with vermicomposting has been used at Monroe for over 24 months, treating over 10,000 lbs/month of unsorted food scraps. Using fermentation to preprocess food scraps has not been overly expensive or time consuming. It does require additional space both for preparing the bran and for pretreating the feedstock. Based on the results from Monroe, pretreatment with Bokashi was an effective means to expand the types of food scraps suitable for vermicomposting at a relatively low cost.

Black Soldier Flies

Not content with the successful two-stage system of fermentation and vermicomposting, Nick and others in charge of the operation found information on using black soldier flies as a way to do single stage treatment and end up with a high value product. Utilizing food wastes as a substrate to raise bugs for a range of end uses was recently profiled online at “Bugs Eat Our Food Waste”. Black soldier flies larvae are typically used as animal or fish food, as they are high in both protein and fats. A major difference between using flies and worms to eat the food is the end product. With worms, the worm castings are commonly considered to be a type of compost. Adding fermentation on the front end of that process still yields the same end product. Using black soldier flies, the primary end product is the flies themselves. Identifying or including an end use for them is critical to making this a successful operation.

As was the case when starting worm composting, the primary focus of the initial stage of the black soldier fly project at Monroe Correctional was breeding a sufficient number of flies, which come as grubs. The grubs were put in buckets with worm castings and dry leaves and allowed to turn into flies. This stage took about two weeks.

It worked to have separate areas for breeding, hatching and for feeding the larvae. The hatching and feeding bins can be designed to be stackable. The key findings were that the flies need sufficient moisture and heat to breed. Light is also critical. Artificial light is sufficient in cases (winter or the basement) where natural light is not available. It is also important to get the flies to lay their eggs in places where they will hatch and where they can be collected.

If handled properly the fly larvae will eat about twice as much pre and postconsumer food scraps as the worms. One might compare them to flying pigs. The group estimates that optimal consumption would total 2 to 3 pounds of food scraps per day per square foot of surface area. With an 8 square foot area, the soldier flies were able to consume 90 pounds of food waste and the managers were able to harvest 13 pounds of pupating larvae per week. This type of operation would make sense if the goal were to produce a value added product or to feed into an aquaculture system. To make full use of this approach, some method to process the worms, or access to aquaculture would be required.

The work at Monroe Correctional Facility has shown that with sufficient human power and attention, it is possible to build and maintain food scraps diversion with low capital investments. All three options were tested and all were found to be effective. They lower waste management costs and provide training for inmates. As anyone who has built a living system from scratch knows, they also provide a great deal of satisfaction. Clearly then, these on-site management practices could be adapted to other prison systems.

Nick Hacheney is Compost Lead at Monroe Correctional Facility in Monroe, Washington. Sally Brown is a Research Professor at the University of Washington in Seattle and a member of BioCycle’s Editorial Board.