First article in 5-part series discusses issues related to feedstock acceptance and management, and reviews main categories of compostable, digestible and edible organics. Part I

Rich Flammer

BioCycle January 2017

The traditional definition of resource management focuses on virgin soils, surface and ground waters, forests, grasslands, wild fauna and flora and elements of primarily natural areas that may or may not be being mined, farmed, forested or used for grazing. Once resources are removed from these places and sold as commodities or become a component of some other product manufactured for sale, both their perceived and actual value peaks and then sharply declines when deemed “waste.”

The traditional definition of resource management focuses on virgin soils, surface and ground waters, forests, grasslands, wild fauna and flora and elements of primarily natural areas that may or may not be being mined, farmed, forested or used for grazing. Once resources are removed from these places and sold as commodities or become a component of some other product manufactured for sale, both their perceived and actual value peaks and then sharply declines when deemed “waste.”

Conversely, the contemporary definition of resource management considers these materials — a high percentage of which have maintained most of their original integrity and composition — valuable throughout their life span, and endeavors to maximize their intrinsic value by handling them in a way that, as much as is possible, preserves their original character or composition and fosters their return to enhance natural cycles, as well as their socioeconomic value.

How to maximize the value of organic materials to foster their return to enhance natural cycles is critical, and the organics resource management industry plays a key role. Every operation has its own set of variables related to state regulations, local zoning and land use rules, weather, climate and microclimate, budget, management structure, etc., as well as other unique challenges and opportunities associated with the region they’re operating in. The flora, geology and even elevation come into play. Being mindful of feedstock character, and volume, should always be of paramount concern, but its importance is often underestimated, misunderstood and sometimes even overlooked entirely. Hence, there are a multitude of questions, challenges and issues — as well as improvements, opportunities and synergies — worth examining from a feedstock-based perspective.

Questions to be tackled in this five-part series include:

• If our societal goal is to progressively divert higher and higher volumes of compostable, digestible and edible organics (CDEs) from landfills and incinerators until this entire disposal segment is removed, how will development of more sustainable processing technologies keep up with the volume, and are current technologies available suitable for all types of CDEs generated?

• Can one system or technology efficiently process all compostables, or are multiple systems required?

• For effective handling of the entire compostable stream, can feedstocks still be commingled, or would they be best collected separately?

• How much focus on feedstock character should policy and regulations address? Should the entire CDE portion of what we generate and dispose of be considered for processing, or should systems be designed purely with the end product in mind and only accept the highest quality feedstocks with the right composition, nutrient values, cellulose content, etc.?

• And if this were the case, where would all of the other CDEs go?

Answers to these questions as well as others pertinent to CDE management will be covered. Part I discusses bigger picture issues related to feedstock acceptance and management, and includes categorization and a character, volume discussion. Part II will explore why CDEs are not suitable for landfill or incineration, and discuss the hierarchy of processing technologies based on environmental, market and “true cost” values and impacts. Part III will examine how these materials are typically collected, disposed of and processed, and how their chemical and physical make-up react to how they are handled, affect their suitability for various processing methods, and determine their volatility. Part IV will look at feedstock-specific management considerations, focusing on composting but also other methods and technologies such as food donation, animal feed, direct land application, anaerobic digestion and pyrolysis. Part V will examine public perception, contamination and regulatory issues, as well as a summation of findings and suggestions for a truly sustainable approach to handling these increasing valuable resources.

An underlying theme of this series is consideration of a highest and best use approach to CDE management — versus fitting whatever wide array of feedstocks are generated and available into a preestablished technology or system. To put it simply, when the sheer volume of feedstock is more critical to an operation’s bottom line than its character or importance to processing efficiency and end product quality, the business model follows a front-end, waste management approach. This can lead to unintended consequences and business pressures that jeopardize the organics recycling operation. Odor issues at composting facilities, for example, are often a result of overcapacity and a front-end business model.

Feedstock Categories

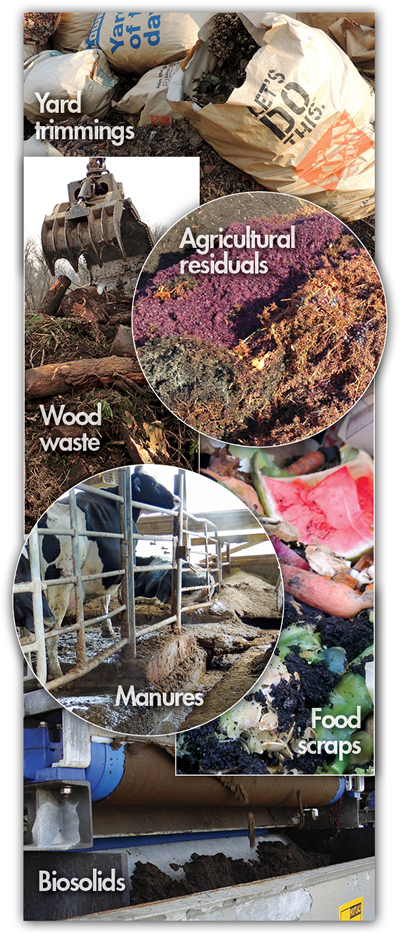

Historically, CDEs have fallen into a few broad categories:

Yard trimmings are a residual with intrinsic value to natural nitrogen, carbon, water and organic matter cycles. This feedstock category includes leaves, grass, brush, tree trimming chips and various whole or trimmed parts of plants, trees and shrubs. Palm and succulents also fall into this category, but are often frowned upon and not accepted by many facilities as they can be tough on grinders.

In some regions with seasons and deciduous trees, such as the Northeast, Northwest and Midwest, yard trimmings may be almost entirely leaves in the fall and a mix of leaves, grass and brush in the spring. In subtropical zones, yard trimmings are commonly mixed materials throughout the year, with some seasonal variations. Yard trimmings may also include some fruits, vegetables and nuts generated from nonfarm sources like home gardens or commercial landscapes. In 2014, over 21 million tons of yard trimmings were composted in the U.S. Total generation of this material was approximately 73 million tons (U.S. EPA, 2016).

Wood waste, in this context defined as “unpainted, untreated dimensional lumber,” is often commingled with brush and yard trimmings and composted. While a good bulking agent, separation for reuse as lumber is preferable. Some 16 million tons of this material are generated in the U.S., and about 2.6 million tons are recycled or composted. (Ibid, US EPA)

Agricultural residuals are frequently composted on the same farm where they are generated. Few farmers want to pay to dispose of or transport crop residuals offsite when the option exists to till them into the soil or compost them on their property. Both local land use codes and state regulations typically allow farms to compost their own residuals without requiring a permit. Importing material for composting or selling the end product often kicks the operation into higher regulatory tiers. Unfortunately, composting is rarely, if ever, viewed by regulators as an agricultural activity. Generation and diversion rate data is difficult to calculate for this agricultural segment, although in some states, such as California, new reporting requirements will provide greater detail (see sidebar).

Manures may be composted or digested onsite or transported to an offsite facility. Manures vary greatly depending on the diet of the animal. Some facilities are selective about which manures they accept due to concerns about salts, pathogens and/or herbicides or other chemicals such as larvicides and equine insect control supplements. Carnivore manures have a broader range of potential pathogens, and higher potential for presence of Salmonella and pathogenic strains of E. coli. Manure from carnivores and omnivores such as pigs can contain helminths (parasistic worms) as well as Campylobacter jejuni and Listeria monocytogenes (pathogenic bacteria), and Cryptosporidium parvum and Giardia lamblia (parasitic protozoans) [Guan and Holley, 2003; Hutchison et al., 2004, 2005a; McLaughlin et al., 2009a].

Most manures composted in the U.S. come from dairy cows, beef cattle, swine, poultry and horses, which collectively generate over 100 million tons of manure each year. How much is currently composted is unknown. The amount of manure processed in farm-based anaerobic digesters is gradually increasing. The U.S. EPA’s AgSTAR program reports that as of May 2016, there are 242 operational farm digesters in the U.S.; the majority (196) are on dairies (www.epa.gov/agstar).

Food scraps is a term semantically more beneficial to improve perception issues than the traditionally used category of “food waste.” These organics fall into their own category and are typically regulated as such. This category has many subdivisions, including a portion still suitable for human consumption, vegetative, preconsumer (“prep”), postconsumer, “front of the house,” “back of the house,” commercial, residential and commingled with yard trimmings, among others. This category also includes food soiled paper. More than 38 million tons of food scraps are generated in the U.S. each year, with 5.1 percent, or 1.94 million tons composted (US EPA, 2016). Although seemingly a meager percentage, this is more than a 100 percent increase since 2000, when 2.2 percent of food scraps were captured for composting.

Biosolids are primarily generated from wastewater treatment plants (WWTPs), and are handled a multitude of ways, including direct land application (on both agricultural and nonagricultural lands), landfilling, composting and digestion. There are approximately 16,000 municipal WWTPs operating in the U.S. These facilities collectively produce about 6.7 million dry tons/year of biosolids, equating to about 42 lbs/person/year. But inputs also include industrial residuals.

Biosolids are not always included in discussions and evaluations of compostable feedstocks, due to an already well-established system of collection and processing, and controversy about whether or not they belong, composted or raw, to be returned back to the earth. But a look at their primary composition confirms they indeed are best digested or composted, with nutrients, microbes and organic matter appropriate for improving soil (see “Building Sustainable Sanitation Systems,” November 2012).

Appropriate methods and technologies exist for source reducing, handling and processing all of these feedstocks. Some are simple and centuries, if not milleniums old, others are complex, developed and fine-tuned in the past 50 years or so. Part II of this series delves into why CDEs are not suitable for landfill or incineration, and discuss the hierarchy of processing technologies based on environmental, market and “true cost” values and impacts.

Rich Flammer of Hidden Resources, a BioCycle Contributing Editor, is a composting and zero waste consultant (www.compostingconsultant.com).