Top: The Sievers Family Farms in Stockton, Iowa. Photos courtesy Sievers Family Farms

Juliana Beecher

Recently released research findings, based on a partnership between Iowa State University and a family farm in eastern Iowa, highlight the benefits of applying digestate derived from anaerobic digestion of cattle manure, plant biomass, and food waste to farm fields. “Digestate effects on soil organic carbon (SOC) and soil fertility are poorly understood, especially at the field scale,” reads the research paper, published in the Journal of Agriculture and Food Research in July 2025. The study spanned 12 years and 14 fields planted in a standard corn-soybean crop rotation. Though the effects of digestate on soil fertility — contributing nitrogen (N), phosphorus (P) and potassium (K) to the soil — are better understood, this study quantified an increase in soil organic carbon (SOC) due to digestate application.

Anaerobic digestion (AD) is valued on commercial farms as a manure management solution and for biogas production, a diversified source of income for livestock producers and farmers. Authors of the study hope their findings will expand interest in incorporating digestate use and complementary soil management practices more holistically into wider systems, encouraging farmers to look beyond the field scale (the agronomic standard) and into the broader contexts of local nutrient flows, industrial inputs, ecosystem services, stacked economic benefits, and soil health. For the farmers, working with a land-grant university helped them quantify the overall soil health and soil tilth benefits they’ve been seeing from digestate application.

Sievers Family Farms

As part of its feedlot expansion, Sievers Family Farms added two covered cattle barns and installed two anaerobic digestion tanks.

Bryan and Lisa Sievers farm 1,800 acres in eastern Iowa. In 2007, the Sievers wanted to expand their beef cattle feedlot while also lowering their carbon footprint. “Manure management was an afterthought at that time,” Bryan Sievers admits, describing open-air feedlots with manure running downhill into a lagoon. He learned about AD and toured digesters in Europe with his father and son. When the feedlot expansion occurred, adding two covered cattle barns, they simultaneously installed two continuously-stirred tank reactor digesters, each with a capacity of 970,000 gallons. Those two digesters came online in 2013 to handle manure from the 2,400 head of cattle.

A third lagoon-style digester was added in 2024 to provide additional gas storage and produce additional biogas. “This extends the hydraulic retention time of our digestate from 30 to 35 days to 40 to 45 days, which improves biogas production and reduces odors and other fugitive gases such as nitrous oxide, hydrogen sulfide and ammonia,” notes Sievers.

The AD system and farm circularity have come a long way since installing the original digesters. Biogas, initially used to generate electricity, is now upgraded to renewable natural gas (RNG) and injected into a pipeline. Early challenges with digestate consistency have given way to a stable, predictable process. When the digested solids are separated out, they are around 65% moisture and 35% dry matter. After being separated from the solids, some liquid digestate is mixed with manure to ensure a pumpable, more consistent product. Most of the liquid digestate is injected into the soil in the fall or early spring before planting corn. After the grain is harvested and corn stover is removed from the fields, the solid digestate (or “biofibers”) is broadcast on fields the following winter or early spring. Corn stover is used for bedding in the cattle barns, where it mixes in with manure and ends up in the digester.

In alternate years, fields are planted with corn or soybeans under no-till or low-till management. Corn requires a lot of N, and digestate has almost fully replaced synthetic N fertilizers on the Sievers’ farm. “The digestate contains adequate amounts of N for 250 to 300 bushels/acre corn crops,” explains Sievers. A small amount of liquid N is added on occasion to increase efficacy of the weed control products applied, and Sievers hopes that N will come from liquid digestate in the future.

Digestate is also rich in P and K, and generally contains more of both than corn needs. In their nutrient management plan with Iowa’s Department of Natural Resources (DNR), Sievers Family Farms is allowed to apply two years’ worth of P and K at one time. That means digestate applications that happen every other year also supply P and K for soybeans planted in alternate years. P and K are starting to build up in some of the Sievers’ fields, which means cutting down on digestate applications. Extra digestate is trucked to neighboring farms and applied. The Sievers have 3,300 acres in their manure management plan. They charge for trucking and applying, but in some cases, not for the digestate itself. “When we first started using digestate, we couldn’t give it away,” Sievers exclaimed. Now, he has neighbors who rely on it for P and K, and would take more if it were available.

Starting in 2014, the Sievers began accepting food processing waste to add to the digesters. More recently, the farm has been experimenting with adding plant biomass from winter-hearty cover crops (e.g. cereal rye) and native reconstructed prairie plantings. About 38 acres of the farm have been restored to native prairie. Roughly one-third of this acreage is harvested each August after the upland game bird nesting season is complete, mimicking the disturbance from fire or ranging animals (e.g. buffalo) that is part of native prairie cycles. The harvested biomass is added to the digesters.

“Since we started processing cellulosic biomass from winter-hardy cover crops such as cereal rye in the winter of 2024-2025, we haven’t noticed a change in any physical, chemical, or biological properties of the digestate,” says Sievers. “More research is necessary in this area, however. The food processing waste varies in terms of N and C, and does have an effect on the digestate. Lab tests are conducted regularly on the incoming food waste and the digestate.”

Cover crops and native prairie plots are part of Sievers’ plan for increased circularity and soil health. He credits Rudi Roeslein of Roeslein Alternative Energy as a partner in both the digester business and in envisioning more fully integrated AD systems in agriculture. “Rudi wants to see 100 million acres of cover crops and 30 million acres of restored prairie in the heartland as a way to provide potential renewable energy feedstocks for digesters,” Sievers explains. This would make it more feasible to build digesters on small and medium-sized farms, where manure alone wouldn’t produce enough biogas to see a return on the investment.

Research Process And Findings

Long-term studies of digestate’s effects on soil health and fertility on a commercial farm scale are scarce in the U.S. Researchers at Iowa State University, in collaboration with the Sievers, measured soil nutrients and carbon stocks in soils across 14 fields that received digestate over 5 to 12 years. Soil sampling occurred three times in the same geo-referenced spots in fields. Historical soil sampling data from a soil lab were used for year 0 (before digestate application) and year 6 of digestate application, which included pH, soil organic matter (SOM), and nutrients P and K.

Iowa State researchers performed the final sampling at year 12 for the longest-running fields (and year 6 for others), and analyzed SOC, soil N, soil particle size distribution, and bulk density in addition to pH, SOM, P and K. Only 6 fields had 12 years of digestate applications at the time of the final sampling. All soil samples were taken at 0 to 15-cm (6 inches) depth. Additional samples were taken at 12 years at a depth of 15 to 30 cm (6-12 inches). The chemical properties of solid and liquid digestates were also analyzed each year. Figure 1 above illustrates the sampling methods and parameters.

During the study period, approximately 10,000 Mg of solid and 75,000 cubic meters of liquid digestate were applied to the Sievers’ fields. Most fields received both liquid and solid digestate; one received only solid and two received only liquid digestate. Application rates varied from 13 to 85 m3ha-1 for liquid digestate and 6 to 144 Mgha-1 for solid digestate. The Iowa soils receiving the digestate are described in the paper as “deep and well-drained silt loam and silty clay loam textures, 3.7% of soil organic matter (SOM), and a pH near 7 in the 0-15 [cm] soil layer.”

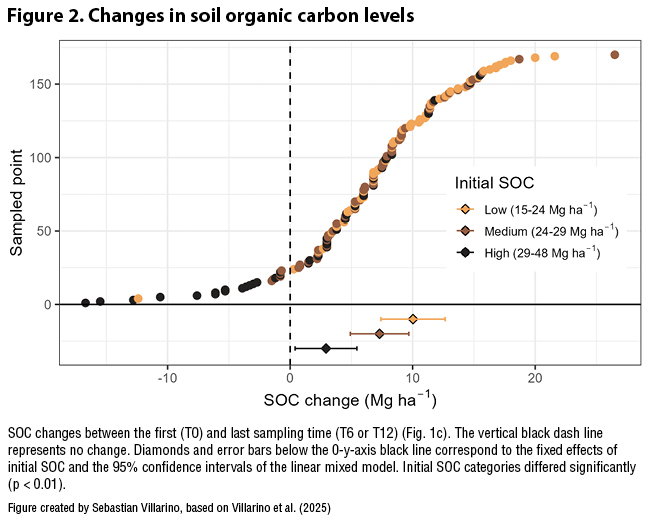

SOC usually takes a long time to respond to changes in land or soil management practices — at least five years — but this study saw changes occur faster than expected. For example, 86% of soil samples analyzed showed an increase in SOC (Figure 2). Soils with lower initial SOC levels saw greater increases with digestate application: 47%, 28% and 9% increases were measured, respectively, for low, medium and high initial SOC levels (22, 26, and 33 MgCha-1 mean initial SOC stocks, respectively, as categorized in the study). Isotope testing helped determine what portion of SOC was derived from digestate.

For the digestate applied to the Sievers’ fields, the authors estimate an 18% SOC formation efficiency — the proportion of carbon in the digestate that is not respired by microbes but stays in the soil. That’s higher than the SOC formation efficiency of 6% to 14% for raw manure cited in other studies. The samples taken in year 12 at 15 to 30 cm showed similar trends, but had no year 0 for comparison. Because most fields received both liquid and solid digestate, it was difficult to say which had a greater effect on SOC, but an average SOC formation efficiency of 18% makes sense based on the C:N ratios of solid and liquid digestate — 27 and 8, respectively — and results from other studies.

Corn needs a N:P ratio of 6 for optimal growth. Digestate has a N:P ratio of 3, providing twice as much P as needed when applied to meet corn’s N demand. If P-laden soil ends up in waterways, it can cause eutrophication, which is a major challenge in Iowa and other agriculture-rich states. Cover cropping and reduced tillage can help soak up available P and keep soil in place, but additional technological fixes like P extraction from digestate may be necessary to avoid pollution risks.

The study authors see the potential of AD integrated into broader farming systems to help reduce agriculture’s climate impacts, increasing food waste diversion, methane capture from manure and RNG production, avoiding use of synthetic fertilizers, and storing carbon in the soil. But questions remain. In addition to excessive P in soils, another pollution risk is nitrous oxide (N2O) emissions from land applied digestate. N2O is far more potent than methane, and emissions may offset some of the GHG benefits realized elsewhere in the system.

Broader Context And Next Steps

Bryan Sievers and Dr. Fernando Miguez, a professor of agronomy at Iowa State and one of the study’s authors, share excitement about increasing the circularity of agriculture. Next, they’re both interested in quantifying the economic benefits of AD integration in agricultural and broader systems, beyond just RNG sales and food waste tipping fees. “Increasing soil C, reducing N inputs — economically speaking, what’s the value?” asks Miguez.

For example, the effects of digestate on crop yield are still unclear. It might be possible to get an estimate by looking at the Sievers’ annual yields compared with corn yield trend lines showing increases due to advances in seed and other technologies. “And weather,” says Sievers. “We have to give credit where credit’s due.” The Sievers saw a record yield in 2024, despite receiving no rain in August, the middle of the growing season. Sievers gives credit to the soil. He’s seen increased water holding capacity since applying digestate. The increase in SOM has helped keep soil moist through periods of drought, and helped rain infiltrate and move more quickly through the soil profile. “I can recall years when we’d have excessive rain and we’d have water ponding in our fields,” notes Sievers. “We don’t see that anymore.”

Some of Sievers’ neighbors are already convinced of the value of digestate. Miguez wants to know what questions farmers and agronomists have after reading this research. “For example, if this result convinces them to replace their nitrogen fertilizer with digestate…I don’t want to tell them that just because we published one paper and because we see things in the lab, this is what’s going to happen in their field. We don’t know. But I would hope it sparks their curiosity about these practices, and we can test on their farms, and continue this work on a broader scale.”

It’s hard to align agronomic, environmental and business variables. Miguez sees the potential in thinking beyond the field or farm scale to the “industrial scale,” where off-site nutrient sources like food waste are incorporated. In his experience, farmers process food waste opportunistically, or because of the tipping fees or biogas potential rather than the agronomic potential. But what if there was more intention in producing digestate for specific fields, based on what those fields need, he asks? And what if fields that are consistently unprofitable are planted in native prairie instead, improving ecosystem functions and providing biomass for energy production via digestion?

Despite the fact that his work in the biogas industry has him spending more time in Washington, D.C., Sievers says he’s still a farmer at heart. “The most rewarding part is not only creating renewable energy, removing emissions from the atmosphere, but also building soil health and seeing those healthier soils produce better yields.”

Juliana Beecher, a Contributing Editor to BioCycle, is a former ORISE Research Fellow with the U.S. EPA’s Office of Resource Conservation and Recovery. She works as a consultant based in Portland, Maine, focusing on bringing the food waste perspective to broader food systems conversations and efforts to build a more resilient food supply chain.