Research study measured digestibility of targeted high value nutrients in three food waste streams in pig-feeding trial.

David Russick and Pedro E. Urriola

BioCycle October 2017

Dried supermarket food waste processed using the mobile dehydration unit (top). Dried food waste mixed into a complete diet for growing pigs (bottom). Images courtesy TUBS, Inc.

Challenges and limitations to converting food waste to animal feed include: Concentration and variability of nutrients; control of pathogens; logistics of collection and processing; and ensuring the digestibility of the converted food waste. The lack of published nutritional information on food waste has limited the confidence of animal nutritionists and producers to use such materials for pork production. The accurate balance of diets for pigs requires not only information on nutrient concentrations but also the digestibility of these nutrients for animal growth. Little to no information on the digestibility of food waste in swine has been published. In vitro (lab) data of protein digestibility of food waste was previously shown to support use of these materials in swine diets (Esteban et al., 2007). In vivo (live) data are needed to determine the value of food waste in swine diets.

Swine Digestibility Study

As a response to this research need, TUBS, Inc., a food waste hauler and processor (originally a solid waste hauler), in partnership with the University of Minnesota Department of Animal Science, conducted a study on digestibility of nutrients in food waste-derived animal feed. The research was funded by the U.S. Department of Agriculture’s National Institute of Food and Agriculture (NIFA). The NIFA project evaluated a patented mobile modular food waste processor (MMFWP) that utilizes a thermal process to dehydrate the food waste and eliminate pathogens while preserving the nutrients. The research performed under the grant was designed to measure the digestibility of targeted high value nutrients for swine. The MMFWP serves as both a collection tank and the processing vessel, enabling food waste sources to be collected and processed separately in order to reduce variability.

TUBS, Inc. and the University of Minnesota housed 36 pigs in metabolic crates to perform three individual feeding experiments. The metabolic crates house individual pigs and enable control of feeding, urine and feces sampling. Food waste from three separate generators was collected: fish waste, supermarket waste (butcher, produce, bakery, and deli departments) and fruit and vegetable waste. The three streams were collected separately and separately processed. The MMFWP produced 500 lbs. of animal feed from each food waste type. The food waste derived animal feed made up 30 percent of the feeding formula.

The team conducted three experiments to measure: 1) Digestibility of the amino acids contained in the proteins in the food wastes; 2) Digestibility of phosphorus (P) in the feed, which can affect P levels in the manures and the land application of those manures; and 3) Energy balance of the conversion process.

Findings And Discussion

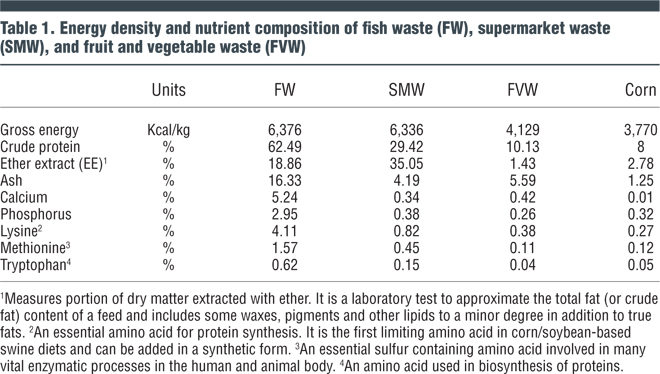

Table 1 summarizes the energy density and nutrient composition of the three food waste streams. Energy and protein account for more than 70 percent of the total diet composition in typical swine diets (Diez-Gonzlaes, 2015). Therefore, the major cost of swine diets comes from the two largest components — energy and proteins followed by phosphorus. Results of the study show that fish waste (FW) and supermarket waste (SMW) are more economically and environmentally valuable in swine feeding programs when compared with fruits and vegetables waste (FVW). Both FW and SMW exhibited high applicability in swine diets with their chemical composition and digestibility of nutrients.

Following the nutrition digestibility study, the University of Minnesota provided a “shadow price” of the food waste-derived animal feed against conventional feed values. Shadow pricing calculates the dollar value of the food waste-derived animal feed as a substitute for conventional feed measured by nutritional content and digestibility. The calculation of value for FW, SMW, and FVW was estimated with a linear programming software that uses the Big M method to formulate diets based on a least cost principle. Three conditions of commodity prices for corn and soybean meal were used in the calculations with prices of corn and soybean meal defined as high, medium, and low from May 2016 to May 2017. References of the commodity prices of corn and soybean meal were obtained from NASDAQ online commodity price chart.

The FW proved to have the highest value as a bulk ingredient for feeding swine in the growing and finishing phase with the price ranging from $422 to $556/ton. The SMW had a value range of $178 to $222/ton. The FVW ranged in value from $133 to $156/ton. This compares with conventional feed values for corn at $148 to $179/ton and for soybeans at $337 to $443/ton.

The environmental impact of replacing corn and soybean meal in swine diets with food waste was calculated based on referenced environmental impact values (Mackenzie et al, 2016). Five factors were considered in the calculation — nonrenewable energy use, nonrenewable resource use, acidification potential, eutrophication potential (nutrient runoff into water systems), and global warming potential. By multiplying these factors to the differences in usage of corn and soybean meal between the conventional diet and the food waste diets, the environmental impact was estimated.

The SMW showed the greatest saving on markers of environmental impact. SMW was projected to save 2,748 megajoules (MJ) of nonrenewable energy and a reduction of global warming potential of 271.1 kilogram of carbon dioxide-equivalent emissions (kg CO2eq) per metric ton of feed produced. Fish waste had a negative energy benefit of -25.83 MJ, which results in a negative environmental benefit as a substitute for corn and soybean meal because of the small amount actually used as a replacement. Fruit and vegetable waste was predicted to save 103.43 MJ of nonrenewable energy and 10.02 kg CO2eq/metric ton of feed produced.

Results from the study suggest that FW and SMW are more economically and environmentally valuable when compared with FVW. Both FW and SMW exhibited high applicability in swine diets with their chemical composition and digestibility of nutrients. The environmental impact calculation reflected the benefits of substituting corn and soybean meal with SMW. The current research provided preliminary information for nutritionists and producers to justify the potential of food waste if used as feed ingredients.

David Russick is a Project Director with TUBS, Inc. in Minneapolis (MN). Pedro Urriola is an Assistant Professor at the Department of Animal Sciences and the Department of Population Medicine at of the University of Minnesota (UMN). Other participants on the UMN science team include Dr. Gerald Shurson, Professor-Swine Nutrition, and Chi Fai Leonard Fung, a Master’s student.