Effluent from an on-site liquifier that processes cafeteria food waste was tested for suitability as irrigation water.

John H. Dorsey and Joe Rasmussen

BioCycle September 2012, Vol. 53, No. 9, p. 26

Raw food waste is loaded into the machine; large aluminum paddles (below) spin continuously, breaking up food waste particles. A mixture of microorganism and enzymes is added weekly; small plastic chips (shown at left) act as bulking agent.

The ORCA system is a food digester, also described as a food liquifier, which converts raw food waste into a liquid effluent through microbiological activity. This system consists of a heavy-duty stainless steel rectangular box with a rotating drum inside. Kitchen staff open the top hatch and dump raw food waste, including vegetables and meat scraps (with the exception of bones), into the machine. The ORCA runs 24-hours/day and can be fed continuously as long as space is available in the machine. Large aluminum paddles attached to a stainless steel shaft spin continuously, physically breaking up the food waste into smaller particles.

A proprietary mixture of microorganisms and enzymes are added on a weekly basis to ensure rapid decomposition. Plastic chips are put in the main chamber as a bulking agent for the food waste. Over the course of one to two days, raw food waste is broken down by various microorganisms and digested into particles that can fit through small holes in the bottom of the machine. These small food waste particles are flushed through the system, ultimately exiting as a liquid effluent with no other resulting by-product.

The company that sells the ORCA, Totally Green, Inc., claims the liquid effluent discharged from the ORCA can be “reused for irrigation, farmland, & gardens” (www.totally green.com/). Preliminary discussions by LMU faculty, students and staff resulted in a strong interest in studying the suitability of using the ORCA effluent as nutrient-laden irrigation water for landscaped areas of the LMU campus grounds. A research plan was developed to answer the following questions: What are the chemical, physical and biological properties of the ORCA effluent? Is the ORCA effluent suitable for irrigation purposes?

The small food waste particles are flushed through the system, ultimately exiting as a liquid by-product.

Methods

During the Spring semester of 2012 (February through April) a team of LMU undergraduate students and a graduate student from California State University, Northridge conducted a suite of chemical, physical and biological water quality tests on ORCA effluent. Results of these tests were compared with values typical of domestic raw sewage. It was reasoned that if constituents in the ORCA effluent, like organic matter or any harmful bacteria, were less in concentration than characteristic of domestic raw sewage, then the effluent would be suitable for irrigation given its potential high nutrient content.

Effluent samples were collected nearly weekly on seven occasions during the early afternoon. During each sampling event, three aliquots were extracted from the effluent sample and tested for a suite of water quality parameters. Chemical and physical tests performed included biological oxygen demand (BOD), total solids and nutrients (nitrate, phosphate). Table 1 includes the test methods. One sample of effluent was sent to a consulting laboratory for determination of fats, oil and grease.

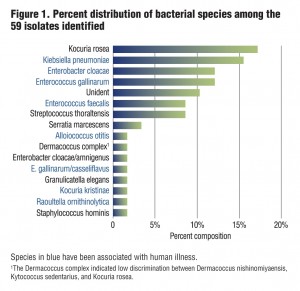

Microbiological tests focused on determining concentrations of fecal indicator bacteria (FIB, including total coliforms, E. coli, enterococci), followed by species identification of cultured isolates to determine if potentially pathogenic strains were present.

Results And Discussion

The ORCA effluent was very strong in organic matter as reflected by the high BODs, FOG and total solids content. These parameters were greater in concentration than typically found in domestic raw sewage (Table 1). Although nitrates were high relative to domestic wastewater, the mean concentration of ORCA orthophosphate was similar (Table 1). Variability of the effluent was great as reflected by the high standard deviations associated with each of the parameters. It was observed that the effluents ranged in color from beige to rose depending on the weekly menu and changing composition of food waste.

Tests for FIB indicated that concentrations of these bacterial groups are similar to those found in low-strength raw domestic sewage. Total coliform and enterococci concentrations were similar to those reported in other studies, while E. coli concentrations were lower (Table 2). The value given for raw sewage concentrations of E. coli in Table 2 actually is for fecal coliforms of which E. coli is estimated to comprise about 90 percent (APHA 1998). This species normally lives in the guts of warm-blooded organisms, but can exist externally in the environment provided resources are present and abiotic conditions are favorable (van Elsas et al. 2011). Its occurrence in the ORCA effluent at low densities is not surprising given the chance of contamination of food scraps by people eating or working in the cafeteria and kitchen.

Based on the organic content of the ORCA effluent, and the presence of the potentially pathogenic organisms, the LMU research team concluded that the effluent must be discharged directly into the sanitary sewer system as is now being done. If kitchen staff must be exposed to the effluent, then they should wear the proper protective clothing as if they were dealing with human sewage. Given these restrictions, ORCA effluent should not be used as “grey water” for irrigation of landscaping. Although nutrient content is high in the ORCA effluent, some of the associated bacteria preclude its use for irrigation.

Implications

The ORCA system is marketed as a technology that contributes to cost savings over time by reducing solid waste disposal bills. For LMU, it is a tool that will reduce the solid waste contributed by the university to the local landfill. By using the system, LMU could divert an estimated 2 tons/week at a cost-savings of about $4,000/year.

One of the next steps of this project is to conduct a cost-benefit analysis to determine the economic viability of the ORCA system (aside from avoided landfill costs(. This would include not only assessing the amount of solid waste processed through the ORCA, but also determining the amount of water used. The analysis would also include metering electricity consumption associated with the system. All of this information will be compared with LMU’s overall carbon footprint to find out if this technology truly is a sustainable system.

John H. Dorsey is a Professor in the Department of Civil Engineering & Environmental Science at Loyola Marymount University (LMU) in Los Angeles. Joe Rasmussen is Sustainability Manager and Lecturer at LMU.