Food Safety Modernization Act rules, finalized in November 2015, guide compost and water use on produce farms.

Craig Coker

BioCycle July 2016

The Food Safety Modernization Act (FSMA) was finalized (Pub. L. 111–353) on November 27, 2015, amending Chapter 2, Parts 11, 16 and 112 of the Code of Federal Regulations to set standards for the growing, harvesting, packing, and holding of produce for human consumption. These rules are administered by the Food and Drug Administration (FDA), which is within the U.S. Department of Agriculture. The rules were first proposed in May 2013 and the FDA received over 15,000 distinct comments on the draft rules. Several provisions created some concerns among organics recyclers. While the final rules have multiple elements, two of potential importance to organics recycling industry participants are Preventive Controls and Produce Safety.

Preventive Controls

Preventive controls are aimed primarily at human food and animal food. This part will be most applicable to on-farm composting facilities that also have animal herds fed, in part, with recycled food scraps and to those facilities taking in commercial food scraps for composting, as it is designed to reduce potential health and safety risks to facility employees.

The preventive control rules for animal foods establishes Current Good Manufacturing Practices (CGMPs) for animal food production facilities and for human food facilities that sell a by-product for use as animal food. A facility already implementing CGMPs for human food consumption (i.e. a brewery) need not implement new CGMPs for residuals going to animal food (fruit/vegetable residuals, spent grains, etc.) other than to implement methods to prevent physical and chemical contamination. Further processing a by-product for use as animal food (e.g., drying, pelletizing, heat-treatment) requires companies to process the by-product in compliance with CGMPs to ensure the safety of the animal food and to make sure that the processing does not introduce hazards. The company can choose to follow either the human food or animal food CGMPs when further processing the by-product. Labeling that identifies the by-product by the common or usual name must be affixed to or accompany human food by-products for use as animal food when distributed.

Produce Safety

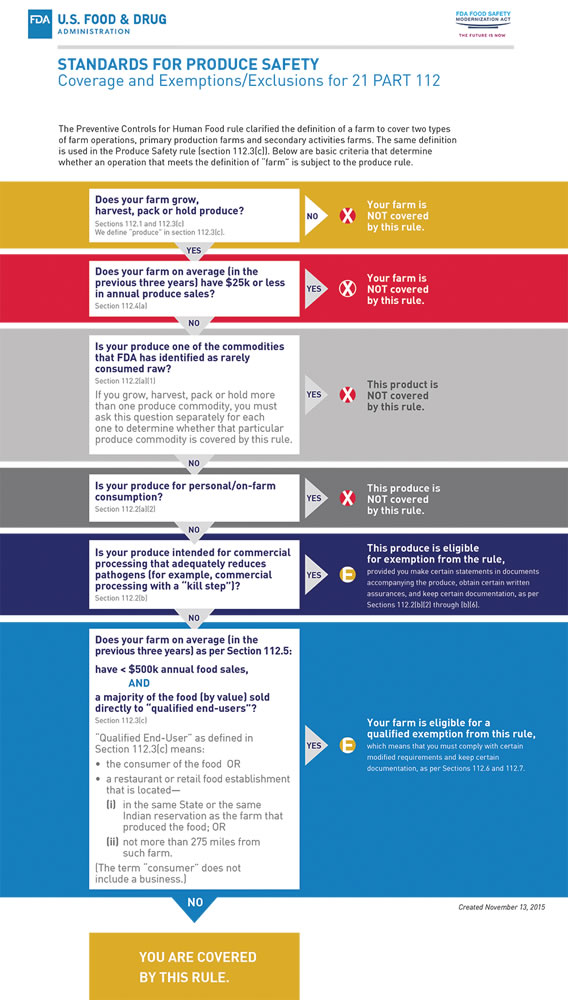

The Produce Safety rules apply only to farms that: Grow, harvest, pack or hold produce for off-farm consumption; have more than $25,000 in annual produce sales; don’t grow produce the FDA considers “rarely consumed raw” (i.e. asparagus, eggplants, okra, etc.); don’t send their produce to a commercial processor; and meet certain other criteria. Two areas in the Produce Safety sections of the new rules relevant to organics recyclers are Agricultural Water and Biological Soil Amendments.

The increase in storm water runoff regulations in recent years, and the no-discharge requirements in many states, are leading composters to look for more innovative ways to handle storm water runoff. Recycling storm water runoff as crop irrigation water may be a viable alternative for some sites. In FSMA, ”agricultural water” means water used to grow produce crops covered by these rules, which, in some cases, could be sourced from the storm water management ponds of composting facilities. Insofar as “agricultural water” is defined by usage and not source, this part should also apply to the direct land application of liquid digestates from anaerobic digestion to crops covered by the rule. (FDA frequently-asked-questions document on requirements for water quality and testing of irrigation water)

The final rules establish two sets of criteria for microbial water quality, both based on the presence of generic Escherichia coliform bacteria (E. Coli), an indicator of the presence of fecal contamination. The first set of criteria state that no detectable generic E. coli are allowed for certain uses of agricultural water in which it is reasonably likely that potentially dangerous microbes, if present, would be transferred to produce through direct or indirect contact. Examples include water used for: 1) Washing hands during and after harvest; 2) On food-contact surfaces; 3) To directly contact produce (including to make ice for storage and shipment) during or after harvest; and Sprout irrigation.

The second set of numerical criteria is for agricultural water that is directly applied to growing produce (other than sprouts). The criteria are based on two values — the geometric mean (GM) and the statistical threshold (STV). The GM (essentially, the average amount of generic E. coli in a water source) of samples is 126 or less Colony-Forming Units (CFU) of generic E.coli per 100 milliliters (mL) of water and the STV (the level at which 90 percent of the samples are below the value) of samples is 410 CFU or less of generic E.coli in 100 mL of water.

Farmers with agricultural water that does not initially meet the microbial criteria have additional flexibility by which they can meet the criteria and then be able to use the water on their crops. These options include, for example:

- Allowing time for potentially dangerous microbes to die off on the field by using a certain time interval between last irrigation and harvest, but no more than four consecutive days;

- Allowing time for potentially dangerous microbes to die off between harvest and end of storage, or to be removed during commercial activities such as washing, within appropriate limits; or

- Treating the water.

Farms regulated under these rules are required to test irrigation water. For untreated surface water (such as composting facility storm water runoff) directly applied to growing produce (other than sprouts), the FDA requires farms to do an initial survey, using a minimum of 20 samples, collected as close as is practicable to harvest over the course of two to four years. The initial survey findings are used to calculate the GM and STV (these two figures are referred to as the “microbial water quality profile”) and determine if the water meets the required microbial quality criteria. After the initial survey has been conducted, an annual survey of a minimum of five samples per year is required to update the calculations of GM and STV. The five new samples, plus the previous most recent 15 samples, create a rolling dataset of 20 samples for use in confirming that that the water is still used appropriately by recalculating the GM and STV.

Biological Soil Amendments

Biological soil amendments are defined in FSMA as “a material, including manure, that is intentionally added to the soil to improve its chemical or physical condition for growing plants or to improve its capacity to hold water.” Microbial standards that set limits on detectable amounts of bacteria (including Listeria monocytogenes, Salmonella spp., fecal coliforms, and E. coli 0157:H7) have been established for processes used to create biological soil amendments, including manure composting. The standard for Listeria is nondetect; for Salmonella, it is less than 3 Most Probable Number (MPN) per 4 grams (g) of solids; for E. Coli, it is less than 0.3 MPN/g solids.

These rules include two examples of standard composting methods that meet those microbial standards (essentially identical to USEPA Part 503 40CFR):

- Static (forced air) composting that maintains aerobic conditions at a minimum of 131°F (55°C) for 3 consecutive days and is followed by adequate curing; and

- Turned composting that maintains aerobic conditions at a minimum of 131 °F (55°C) for 15 days (which do not have to be consecutive), with a minimum of five turnings, and is followed by adequate curing.

Stabilized compost prepared using either of these methods must be handled and stored in a way to minimize the potential for contamination with pathogenic bacteria and applied in a manner that minimizes the potential for contact with produce during and after application. For composts prepared using the approved methods in the rules, there is no minimum specified interval between application of the compost and harvesting of the produce. Compost tea may not be used on crops subject to these rules if it contains detectable amounts of E. Coli in 100 ml of water.

The FDA has not yet specified the minimum specified interval between application of the untreated manures and harvesting of produce pending the outcome of a risk assessment, although work has been done on recommended setbacks from land application of manures. Recent research and risk assessment by researchers at Clarkson University suggests a distance setback of 160 meters (524 feet) between liquid manure application and leafy green crops (Jahne, M.A., et.al , 2016). Inactivation of pathogens (Salmonella spp., Campylobacter spp., and Escherichia coli O157:H7) on both the manure-amended fields and on crops was considered to determine the maximum loading of pathogens to plants with time following application. Overall median one-time infection risks at the time of maximum loading decreased from 1:1,300 at 0 m directly downwind from the field to 1:6,700 at 100 m and 1:92,000 at 1000 m; peak risks (95th percentiles) were considerably greater (1:18, 1:89, and 1:1,200, respectively). Median risk was below 1:10,000 at >160 m downwind. Due to the reduced bacterial populations in digestates, the risk of exposure due to the land application of liquid digestates from mesophilic anaerobic digesters is believed to be less than that from raw manure land application.

As is often the case with new rules, recordkeeping is required. For biological soil amendments of animal origin, farmers must keep records of off-farm sources and copies of Certificates of Conformance that the compost was made in accordance with these rules. For on-farm sources of compost, records of time-temperature monitoring are needed to demonstrate compliance with the pathogen reduction requirements. For agricultural water, farmers must keep records of microbial testing, Certificates of Compliance from off-farm sources, and confirmatory data on the effectiveness of any water treatment used. Farms will be subject to inspections where these farm-kept records must be made available for review. The FDA is working with the National Association of State Departments of Agriculture to assess state resources for inspections and to develop suitable protocols.