Top: Zero Waste Energy Development digestion and composting tunnels at facility in San Jose.

Nathalie Hoffman

While renewable natural gas (RNG) produced from dairy and swine manure has received a lot of attention due to the ultra-negative carbon intensities (CIs) possible, the California Air Resources Board (CARB) recently sent a strong signal to the marketplace that RNG produced from food scraps is also very important. The signal came a couple of months ago when CARB certified the first, and to date, only food scraps-to-RNG pathway under the current version (CA-GREET 3.0) of CA-GREET, the California-centric version of Argonne National Laboratories’ GREET model. CA-GREET 3.0 is used to calculate CIs for the state’s Low Carbon Fuel Standard (LCFS).

Within this pathway, 10% of the feedstock on a volume basis is urban landscaping waste, which is also permitted for RNG under the LCFS. The certification was awarded to Zero Waste Energy (ZWE) by way of a Design-based pathway application for a project to be located in Napa, California. The certified CI for the pathway is -165, much lower and therefore much more valuable than the CIs for landfill gas, wastewater sludge or ULW to RNG pathways. A second California food scraps/ULW RNG project is in the public comment period of the LCFS application process, with CARB recommending a CI of -80. The process will terminate with certification at that CI on March 22, 2021 if the applicant is not required to make changes as a result of comments. Part of CARB’s motivation to certify a food scraps Design-based pathway is to help facilitate development of projects that divert them from landfills as required under California’s SB 1383, the Short-Lived Climate Pollutants Reduction Act.

For food scraps-to-RNG producers located outside of California, these recent developments are of great interest because RNG projects don’t have to be located in California to generate LCFS credits. Producers can inject the RNG into a common carrier pipeline wherever they are located in North America and still generate them. On the other hand, liquid biofuels like ethanol, biodiesel and renewable diesel have to be dispensed directly into vehicle fuel tanks located in California to generate LCFS credits.

Zero Waste Energy supplied the equipment and systems for a source separated organics digester in San Jose, California. Photo courtesy of Bulk Handling Systems/ZWE

The LCFS

California Gov. Arnold Schwarzenegger established the LCFS in 2007 through an Executive Order, building on his signing of AB 32, the California Global Warming Solutions Act of 2006. In 2009, CARB adopted the LCFS regulation, which went into effect in January 2011. It aims to incent the reduction of greenhouse gases (GHGs) from on-road transportation in California through a market-based and technology neutral mechanism. There’s an annually-declining CI standard for gasoline and diesel, and each biofuel used on-road that year in California must also have its CI calculated by summing up the lifecycle emissions it generates at every step along its fuel pathway, from “well-to-wheel.” The lower the CI of a given biofuel as compared to the CI of the fossil fuel it replaces, the more LCFS credits are generated. Under the LCFS, ethanol replaces gasoline, and biodiesel, renewable diesel and RNG replace diesel.

Because the CI of a given biofuel has to decline every year to generate the same number of LCFS credits it generated in the previous year vis-à-vis the fossil fuel it replaces, the LCFS incents continuing innovation in the biofuels industry. For example, a recent study demonstrated that the average CI of corn ethanol has declined by 25% in the 10 years the LCFS has been in effect.

As the pioneer regulation incenting the reduction of GHGs from on-road transportation, the LCFS has been amended from time to time as new biofuels have emerged, life cycle analysis (LCA) models have been updated, and CARB has gained experience. The most recent amendment, adopted in 2018, went into effect in January 2019 for fuel pathway applications (FPA) submitted after that date. Although a 10% reduction in the average CI of on-road vehicle fuels by 2020 was initially required, it has since been increased so that a 20% reduction is required by 2030. The LCFS will remain in effect after 2030, although it’s currently unknown if there will be additional percentage reductions in the average CI required.

LCFS RNG Pathways

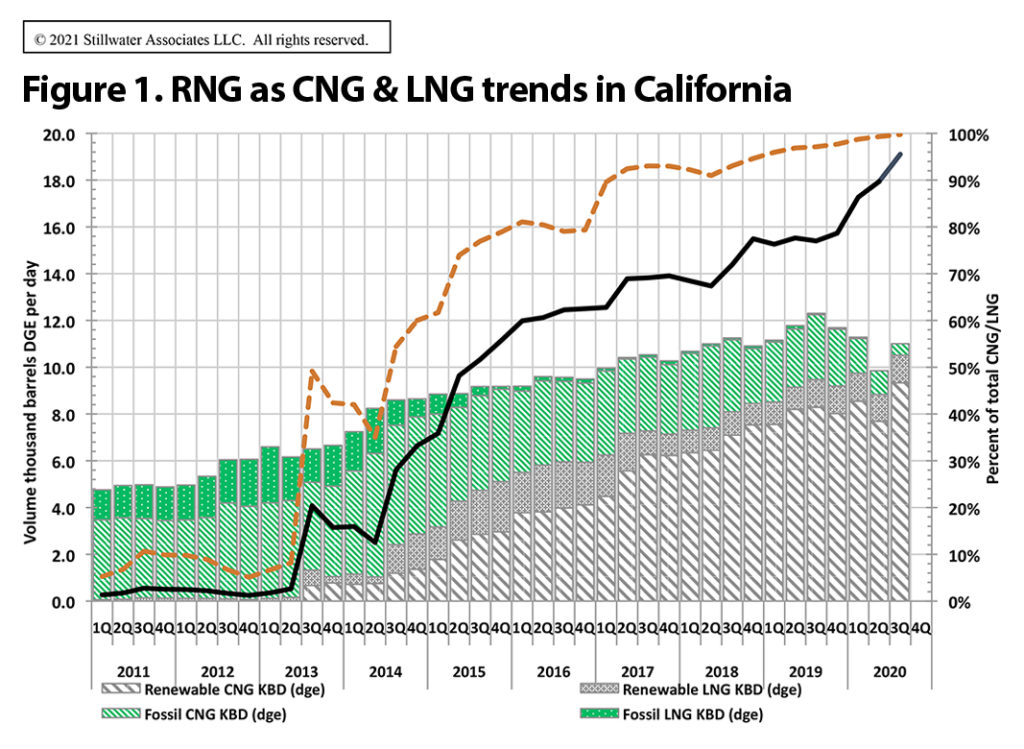

As the LCFS has matured, one of the most important biofuels to emerge has been biomethane, or renewable natural gas (RNG), due to its extreme GHG-reducing properties. As a result, starting from almost no credits when the LCFS went into effect, RNG now makes up almost all of the LCFS credits from natural gas fuels used in California vehicles (Figure 1). California knows that RNG is a necessity if the state is to meet its GHG emissions reductions target by 2030.

Reproduced by permission from Stillwater Publications, the publication arm of Stillwater Associates LLC

Biogas from four feedstock groups are eligible to generate RNG credits: North American landfills, wastewater sludge, organic waste and dairy/swine manure. As noted, dairy and swine manure pathways receive a lot of attention due to their extremely negative CIs. While most of these pathways are in the -250 to -400 CI range, a number have certified CIs lower than -400 — and one dairy manure CI has been certified at a CI of -532.74 gCO2e/MJ. Although 50 landfill gas and wastewater sludge pathways are currently certified, their CIs are much higher — typically in the 45–70 gCO2e/MJ range. Consequently, they are much less valuable than dairy and swine manure CIs.

That brings us to the category of “organic waste,” which has three subcategories: food scraps (FS), urban landscaping waste (ULW) and “other organic waste.” FS is defined as “wastes derived from plants or animals for the explicit preparation or consumption of food or human and animals,” but does not include industrial food processing waste. ULW is defined as the “portion of MSW … that consists of materials resulting from any public or private landscaping activities such as leaves, grass clippings, plants, prunings, shrubs, branches and stumps.” Other organic waste is a user-defined category for waste that doesn’t fall into the FS and ULW categories, and may include industrial food processing waste and agricultural residues. Between FS and ULW, FS results in a far lower CI on an equivalent volume basis, and therefore is a much better feedstock for a LCFS pathway. It’s not possible to know the relative GHG-reducing properties of FS versus other organic waste as a general rule, since the category is user-defined and differs depending on the type.

Fuel Pathway Application

To generate LCFS credits, a biofuels producer must have its fuel pathway certified by CARB. This happens through the fuel pathway application (FPA) process in which the CI of the pathway is calculated on a well-to-wheel basis using the CA-GREET 3.0 model.

There are two possible full and individualized certifications — Tier 1 and Tier 2. Tier 1 is a simplified process where standardized inputs are used in fields in the CA-GREET 3.0 calculator, along with 24 months of site-specific operational data. Tier 2 is the process used for less common biofuels or where the applicant believes it can obtain a substantially lower CI. In Tier 2, the applicant foregoes the ability to use standardized values in non site-specific fields. There are also more steps to the Tier 2 and a detailed report not required in the Tier 1 process must be submitted. Furthermore, the FPA is subject to a public comment period. Therefore the Tier 2 process is more time-consuming and costly.

Another type of certification allows owners of start-up projects to begin generating credits before they have 24 months of operational data. Through a Provisional FPA, project sponsors can obtain certification with only three months of such data. The pathway holder is required to update its operational data every quarter, and once it has achieved 24 months of operation, the provisional status can be removed, subject to compliance with the other requirements for fuel pathway certification.

Design-Based Pathways

In the 2018 amendments, CARB added another type of certification — the “Design-based pathway” — “in order to encourage the development of innovative fuel technologies” (LCFS § 95488.9 (e)). Design-based pathways are a totally separate type of certification because they are for conceptual (although fully engineered and designed) projects as opposed to operating facilities. However, because they require use of an individualized model to calculate the projected CI, they use the Tier 2 application process. CARB’s acceptance of Design-based FPAs for review is discretionary, unlike Tier 1 and 2 FPAs. In addition, they require much more CARB staff time, and consequently, are exceedingly rare. Under CA-GREET 3.0, only three have been certified.

To understand why they’re rare, Tier 1 and Tier 2 FPAs are the norm and CARB has much more experience with them than with Design-based pathways. Tier 1 FPAs don’t require a lot of staff time because they use standardized inputs in the CA-GREET 3.0 calculator fields (not containing site-specific data). Also, CARB has less work verifying operational data than previously, thanks to the 2018 amendment that requires a FPA to be validated by an independent professional verification company before CARB reviews it. Under the validation process, the verification company checks and confirms all of the site-specific operational data so CARB only has to review it at a high level. By comparison, CARB staff has substantially more work to do to certify a Tier 2 FPA, in large part due to additional review processes. For example, individualized data in calculator fields has to be checked and confirmed and the biofuels involved tend to be much less common than with the Tier 1 FPAs.

If CARB decides to proceed with a Design-based FPA, staff will first conduct a detailed evaluation of the submitted information. There is no validation step, so CARB staff has to review every detail of the project itself. These pathways are by definition innovative so CARB doesn’t have the same familiarity with them that they do with Tier 1 and Tier 2 FPAs. The lack of precedents results in a lot of trial and error, which means CARB has to go back and forth with the project developer and through numerous reviews of the project. Once CARB intends to certify the pathway, it will submit it for a 10-day public comment period.

Pros And Cons Of Design-Based Pathway

A LCFS Design-based pathway certification differs from a normal pathway certification in the following ways:

- No operational data is required. As noted, full pathway certifications require 24 months of operational data or alternatively, an applicant must submit a minimum of three months to get a Provisional certification, i.e., the facility must be constructed and operating. However, in the case of a Design-based certification, the facility need only be fully engineered and designed — no operational data is required. The applicant is however required to submit a detailed description of the project with a LCA report of the proposed pathway and a modified calculator spreadsheet.

- No validation process. Design-based pathway fuel pathway applications do not undergo a validation process. Since there is no operational data, there’s nothing for a verification company to validate. The validation process adds expense and requires project staff interface, so not having to go through it is a benefit for the project developer.

- No generation of LCFS credits. Because the facility is not operational, a Design-based pathway is not eligible to generate LCFS credits until the facility is constructed and operating for at least three months. At that point, the applicant can submit a Provisional pathway application to start generating them.

The Design-based pathway may help project developers with project financing. Why? A fully engineered and designed project can show potential investors the CI the pathway is likely to receive with CARB’s stamp of approval while the project is still in the development stage.

Zero Waste Energy Design-Based Pathway

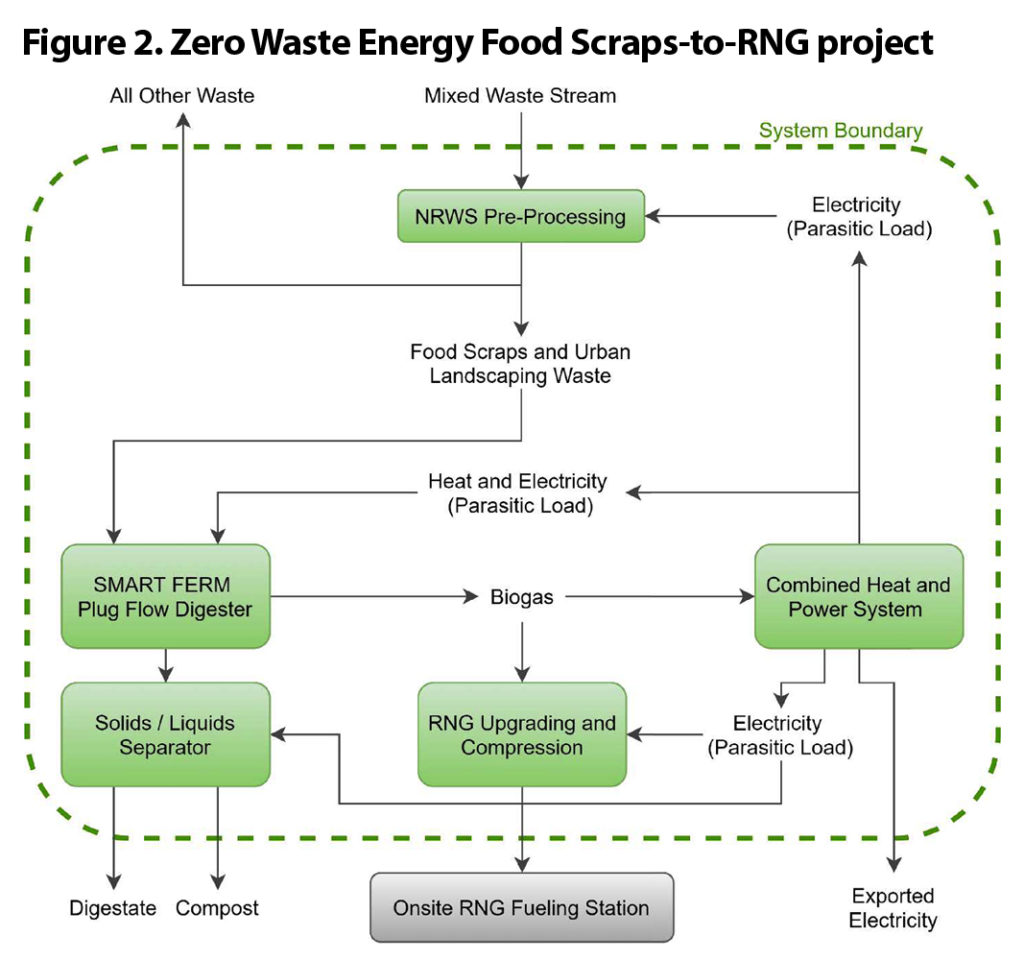

Zero Waste Energy (ZWE), headquartered in San Jose (CA), decided to use the Design-based FPA process for a new dry anaerobic digester and biogas conditioning system it is installing at an existing composting facility owned by the City of Napa and operated by Napa Recycling & Waste Services (NRWS). Feedstock for the project will be 90% food scraps and 10% urban landscaping waste. Figure 2 is a Process Flow Diagram for the ZWE facility.

On a weekly average, about 50% of the biogas will go to the digester’s combined heat and power (CHP) system to meet electricity demand, and 50% will go to the upgrading system for the production of RNG. The RNG will be compressed and dispensed as CNG (compressed natural gas) at an on-site refueling station for the City of Napa’s fleet of garbage trucks. Electricity remaining after meeting the plant’s “parasitic” load will be sold to the grid as renewable electricity. Digestate will be processed into liquid and solid fractions (the latter composted) for sale as liquid fertilizer and an organic soil amendment.

On a weekly average, about 50% of the biogas will go to the digester’s combined heat and power (CHP) system to meet electricity demand, and 50% will go to the upgrading system for the production of RNG. The RNG will be compressed and dispensed as CNG (compressed natural gas) at an on-site refueling station for the City of Napa’s fleet of garbage trucks. Electricity remaining after meeting the plant’s “parasitic” load will be sold to the grid as renewable electricity. Digestate will be processed into liquid and solid fractions (the latter composted) for sale as liquid fertilizer and an organic soil amendment.

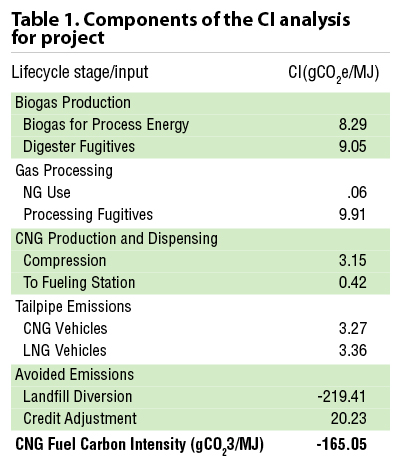

On January 4, 2021, CARB certified ZWE’s Design-based FS-to-RNG pathway for the Napa RNG project. This is first FS-RNG pathway certified under CA-GREET 3.0; its certified CI is -165. Table 1 lays out the CI components of the pathway as certified by CARB. The primary factors contributing to the low CI are use of FS as the feedstock, the methane content of the biogas, and use of biogas to power the project, as opposed to grid electricity.

The recent ZWE Design-based pathway certification demonstrates that LCFS food scraps-to-RNG pathways may be substantially more lucrative than selling biogas from FS to the grid for renewable electricity, given the extremely low CI possible with such a LCFS pathway. Because a Design-based pathway requires substantially more CARB staff time than a Tier 1 or Tier 2 FPA, CARB was no doubt sending a message to the marketplace that it’s interested in seeing more food scraps-to-RNG pathways when it certified the ZWE pathway. The ZWE documents can serve as a guideline for FS-to-RNG FPAs for others applying under the Designed-based pathway. Ultimately, each project will require its own detailed analysis and documentation, reports and modifications to the CA-GREET 3.0 FS-to-RNG model used to calculate its CI.

Nathalie Hoffman is the CEO of LCFS Consulting Services, Inc. She is a certified LCFS verifier and has been advising clients in connection with the LCFS since its inception in 2011. The company estimates LCFS CIs for companies developing biofuels projects or their investors, and has a special focus on RNG pathways. LCFS Consulting also assists companies to prepare and submit their fuel pathway application to obtain certification to generate LCFS credits, and once certified, assists them to prepare the quarterly and annual reports required post-certification.