The economics of an organic “waste to energy” facility are strongly dependent on the waste characteristics, and costs of digestion and solids processing after digestion. Part I

David L. Parry

BioCycle April 2013, Vol. 54, No. 4, p. 48

Anaerobic digestion of organic waste is growing rapidly because of numerous benefits such as diversion of waste to renewable energy, reduction of solid waste by conversion to biogas, biosolids production and reduction of odors. Still there are barriers to the widespread implementation of organic waste digestion. For example, the renewable energy generator may or may not need all the power produced and the value to sell it can be significantly less than the avoided cost of buying it. The economics are marginally profitable. And even though digestion of organic waste is environmentally friendly, environmental regulations are not always supportive, introducing barriers from air, water and solid waste permitting requirements and discouraging organic waste-to-energy (WTE) via anaerobic digestion. Finally, in the case of municipal water reclamation facilities, managers are often resistant to receiving trucked in organic waste because it can be viewed as a risk to their core business of wastewater treatment.

Collaboration is needed between the waste generators and the waste managers to help address these barriers. Research and additional communication can help overcome managers’ fears and improve the economic viability of codigestion facilities. CDM Smith is conducting research on codigestion with the Water Environment Research Foundation (WERF) along with others to find answers on organic loading rates, digester stability and biogas production that is leading to improved economic viability and operator confidence in codigestion. Areas of focus include stability of digestion systems receiving a variety of organic wastes, and developing more sophisticated organic loading rates to enable more aggressive loading while maintaining stability. In turn, higher organic loading rates enable more capacity out of existing digesters and lower costs by installing smaller new digesters for a specified capacity — improving the economic viability of standalone organic waste digestion and codigestion facilities.

A standalone organic WTE facility (i.e., not a wastewater treatment plant digester) has many needs, both in terms of assets and operations and maintenance staff. Waste receiving, predigestion solids processing, digesters, postdigestion solids processing, digestate (biosolids) management, biogas treatment and utilization, and wastewater treatment of sidestreams are all needed and require operation and maintenance (O&M) by trained personnel. Codigestion of organic waste with domestic sludge at municipal water reclamation facilities can be much more favorable economically than standalone facilities.

Many water reclamation facilities have available capacity in existing anaerobic digesters that could accommodate organic waste. They also may have biogas treatment and utilization systems like biogas-fueled combined heat and power (CHP) systems. These water reclamation facilities also have wastewater treatment, solids processing, and biosolids systems complete with O&M staff. Even with all of these favorable conditions for economic viability, most water reclamation facilities would require a tipping fee to cover the cost of receiving organic wastes.

Fortunately, facilities that employ anaerobic digestion to process organic waste are increasing in number as progressive leaders overcome these barriers. These leaders collaborate across divisions between solid waste, waste- water and energy for mutually beneficial and integrated solutions that recover energy, water, biosolids or digestate and nutrients from waste. They find ways to meet the economic challenge or to overcome the aversion to diverting organic waste to water reclamation facilities. Organic waste and energy management are incorporated into their core business, and they manage risk and deal with environmental regulations.

Facility Economics

One of the key drivers for a codigestion facility is economics. Revenue streams need to be greater than the costs by a large enough margin to recover the capital investment. Revenue can be derived from tipping fees for receiving organic waste, biogas production and residual biosolids. The biogas can be used to fuel a boiler or CHP system, sold to a nearby industry, purified to biomethane and sold as renewable natural gas or compressed and used to fuel CNG (compressed natural gas) vehicles. The biosolids can be sold as a soil amendment or as a fuel substitute depending on the local market and solids quality (e.g., Class A or B, dewatered cake or dried pellets, compost, etc.).

Costs include construction and operation of a receiving facility, digestion, biosolids management (e.g., dewatering, drying), sidestream treatment, biogas treatment and use. There also are costs for processing the organics to remove contaminants such as cardboard, plastics, metals and produce a digestible pulp.

CDM Smith conducted an economic analysis as part of the WERF research to gain insights on codigestion and evaluate actual tipping fee requirements for water reclamation facilities. Assuming that preliminary processing of the organic waste is covered by others, the required tipping fee that a water reclamation facility would need to cover its cost for handling an organic waste was calculated for electricity and residual biosolids costs. The costs for an organic waste receiving facility and sidestream treatment were assumed and kept constant. Digestion costs were assumed (medium cost of $5/gallon) and a sensitivity analysis was performed by either assuming existing digesters were used (at no cost) or less digester volume was required because of a higher organic loading rate resulting in a low digester cost.

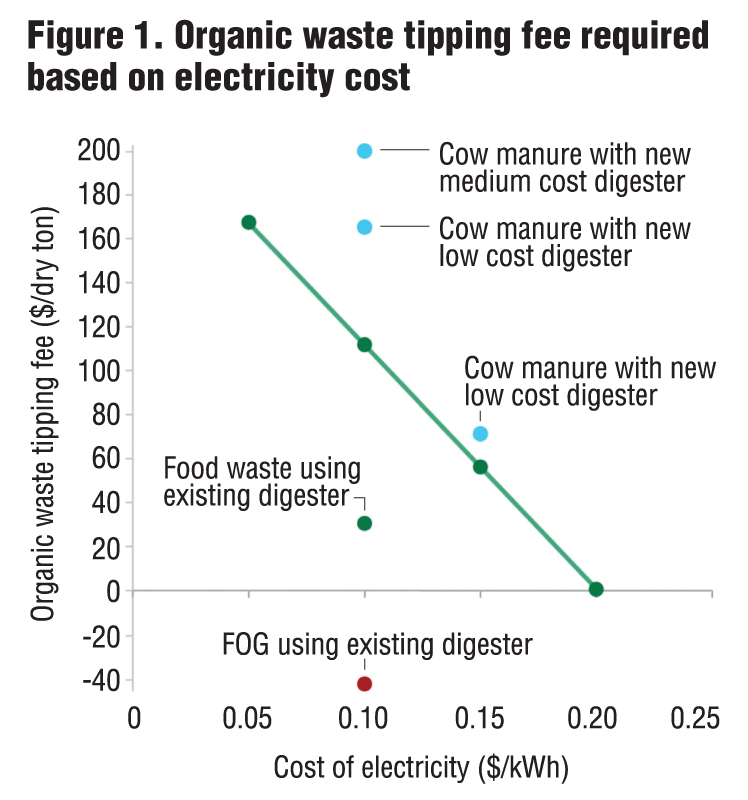

Results of the economic analysis are shown in the accompanying Figures in terms of the required organic waste tipping fee given different electricity (Figure 1) and residual biosolids (Figure 2) costs. The economics of individual organic WTE facilities will vary due to site-specific conditions. In Figure 1, the tipping fees for food waste vary from $0 to $170/dry ton for electricity costs of $0.05 to 0.20/kWh. These fees are based on medium cost digesters ($5/gallon with 0.15 lb VS/day/ft3 loading) and medium cost for biosolids residuals ($200/dry ton). Tipping fee requirements for food waste assuming no cost for an existing digester is shown to illustrate the impact of digestion cost. The fees for cow manure are higher because of the lower VS reduction resulting in less biogas and more residuals. (Cow manure is included in this analysis to show the higher costs for receiving an organic waste with low VS reduction characteristics.) The tipping fee for FOG is negative, indicating that the economic benefits of receiving FOG are greater than the costs. FOG is a much more desirable organic waste for codigestion than cow manure.

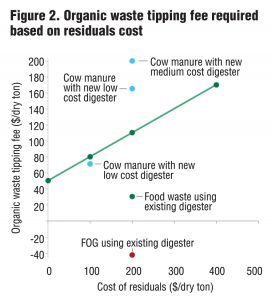

In Figure 2, tipping fees for food waste vary from $50 to $170/dry ton for biosolids residuals costs of $0 to $400/dry ton. These fees are based on medium electricity costs of $0.10/kWh. The fee for codigestion of food waste using existing digesters is significantly lower than having to build a new digester and demonstrates the benefit of codigestion using existing assets at a water reclamation facility. Again, the fee for FOG digestion is shown to be negative indicating an economic benefit.

The economic analysis demonstrates the strong dependence on organic waste characteristics, electricity costs and biosolids residuals costs. The most economic organic waste to energy facility would receive organic waste with high volatile solids and VS reduction, have high electricity rates to get the most value out of the biogas (assuming CHP), and have low residuals management costs.

Subsequent articles in this series on codigestion will cover results from codigestion research funded by WERF, demonstration of converting food waste to biomethane fuel, comparison of food waste management options, and insights regarding operation of codigestion facilities.

David Parry, PhD, PE, BCEE, is a Senior Vice President with CDM Smith.