Top: First of two food scrap slurry receiving facilities at the Los Angeles County Sanitation Distrcts’ JWPCP.

Carol Adaire Jones

A wide range of water resource recovery facilities (WRRFs) have successfully codigested food waste with biosolids. However, as highlighted in a 2019 Environmental Law Institute (ELI) report on business strategies for codigesting food waste at WRRFs, the wastewater sector has substantial untapped capacity for codigestion. The study, funded by the Water Resource Foundation, provided insights and case studies illustrating strategies WRRFs have used to address the range of risks and impediments they face in adopting codigestion.

Among WRRF food waste feedstocks, food scraps are least likely to be codigested, relative to fats, oils and greases (FOG) and food and beverage processing residuals (FPR). One reason is that FOG and FPR are typically managed through the wastewater system and so are known to WRRFs, whereas food scraps are typically managed through the solid waste system and thus are less familiar. Another impediment is that municipal solid waste (MSW) agencies traditionally have not collected them separately. And finally, for food scraps to be suitable as WRRF codigestion feedstocks, they need preprocessing — removing contaminants, reducing particle size, and adding liquid to create a slurry.

Demand for recycling food scraps is increasing, due in part to a growing number of cities and states implementing organic waste landfill bans or organics recycling mandates, and in part to more food sector companies making sustainability commitments, which creates demand for food scrap recycling solutions independent of regulations. With the heightened demand, innovations in food scrap sourcing arrangements are beginning to emerge and break through the impediments.

This two-part article identifies alternative business models for WRRFs sourcing of preprocessed food scraps — regional solid waste/wastewater partnerships and WRRF vertical integration. In the final section of Part II, the different pattern of preprocessing business models adopted by private developers of farm or standalone anaerobic digesters (AD) is noted. Each case study in Part I links to updated ELI profiles on the facilities’ codigestion programs.

Regional Partnerships With Solid Waste Sector

The predominant class of solutions employed by WRRFs sourcing food scraps is regional partnerships between wastewater utilities and the solid waste sector. WRRF partners may be public solid waste utilities, or private resource recovery companies in the solid waste or solid waste-adjacent sectors. In some cases, particularly among the larger facilities, WRRFs employ multiple types of partnerships.

Solid waste partners develop preprocessing strategies suited to the specific context — including meeting WRRF requirements with feedstocks that are available (e.g., single-source collections from grocery stores or manufacturing plants, source separated organics (SSO), mixed solid waste). Among private sector partners are several companies that have developed turnkey pumpable food-scrap slurry products being marketed in different locations throughout the country. From the traditional private solid waste sector, Waste Management (WM) has developed its patented CORe® process, which removes nondegradable contaminants from source separated food waste streams and creates a blended, high energy, consistent slurry (Engineered BioSlurry product (EBS®)). WM currently operates four Organics Recycling Facilities (ORFs) producing EBS, each of which was initially developed with a medium or large WRRF as an anchor customer.

Other private sector partners have core business operations in product lines adjacent to solid waste collection and disposition, out of which a food scrap slurry product line has developed. For example, Divert Inc. uses IoT tools and prescriptive analytics to measure and optimize freshness throughout the retail supply chain to reduce food waste and enhance donation by grocery stores. At facilities in three states, food unsuitable for donation is depackaged, liquefied, and filtered before being sent to third party partner AD and composting facilities. Emerson’s InSinkErator Division, which markets residential and commercial food waste disposers, created a spinoff product, the Grind2Energy system, a distributed non-sewer-based food scrap processing and recycling solution. Emerson has installed Grind2Energy units at approximately 70 sites, primarily grocery stores and commercial food service establishments, and predominantly in Massachusetts and California (two states with landfill bans/recycling mandates) and Ohio and Wisconsin (two states without bans).

East Bay Municipal Utility District

The East Bay Municipal Utility District (EBMUD) WRRF, with ~60 million gallons/day (mgd) average dry weather flow, is located in Oakland, California. It was the first WRRF to adopt food scrap codigestion (in 2004) and the first to produce more energy than it uses on-site (in 2012). To address challenges with contamination in the early years of food scrap codigestion, EBMUD developed a patented on-site pretreatment system in which food scraps are passed through a rock trap/grinder, allowing large pieces of debris to settle out, and then extruded through a screen with rotating blades.

However, EBMUD is shifting to a model where its suppliers assume a greater share, or all, of the responsibility for pretreatment. EBMUD currently has a long-term public partnership for the supply of postconsumer food scrap feedstocks with Central Contra Costa Solid Waste Authority. Republic, the contract hauler, recently added pretreatment equipment at its transfer station in Martinez (CA). EBMUD also anticipates receiving food scrap slurries from another public solid waste utility partner, though the pilot project is delayed because COVID-19 has significantly reduced the flow of commercial organics. Since the solid waste utility will be using the Anaergia OREX 500 press extruder and a polishing system to address contamination, EBMUD anticipates the slurry will go directly into the blend tank.

Central Marin Sanitation Agency

Central Marin Sanitation Agency (CMSA), located in San Rafael, California, partners with Marin Sanitary Services (MSS), a nearby private solid waste hauling company, on their Food2Energy (F2E) program, in which MSS delivers food scraps to CMSA for codigestion. MSS has built many features into its outreach, collection and preprocessing to produce a clean feedstock for CMSA. The 7.5 mgd WRRF runs the F2E food scraps through a rock trap/grinder and screen to remove contamination, having modeled its on-site pretreatment system after EBMUD. To mitigate problems EBMUD has experienced with feedstock contamination, the MSS F2E feedstock is limited to preconsumer commercial food waste. The same solid waste utility that EBMUD anticipates partnering with also has approached CMSA about taking its slurry. This could lead to a pilot project once the commercial sector has recovered from the impacts of COVID-19.

Derry Township Municipal Authority

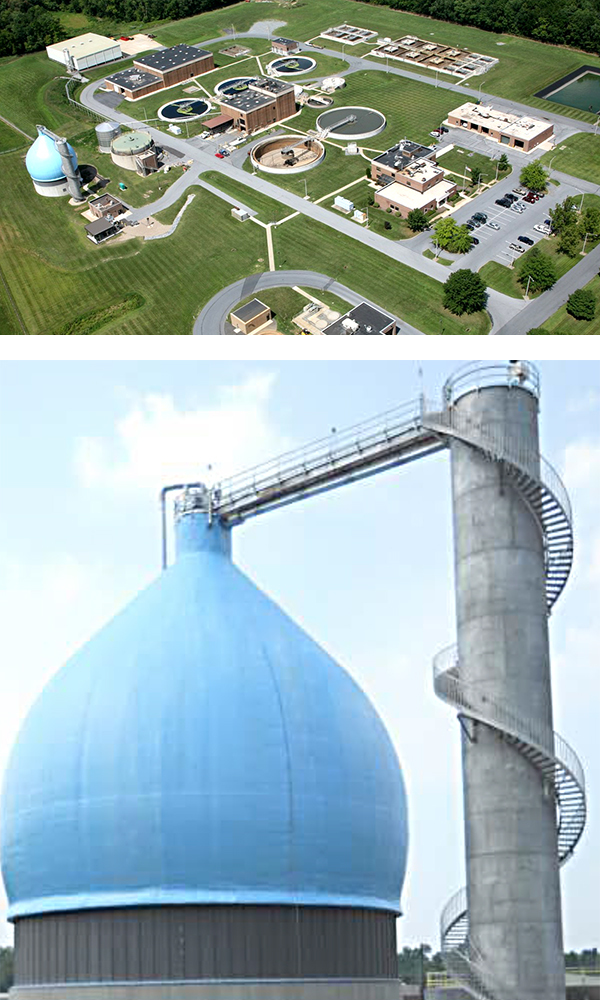

Top: Derry Township Municipal Authority WRRF, Hershey, Pennsylvania.

Bottom: Anaerobic digester at DTMA processes high strength organics, including food scraps, with wastewater.

The Derry Township Municipal Authority (DTMA) Clearwater Road Wastewater Treatment Facility (3.9 mgd) in Hershey, Pennsylvania has a long history of collecting tip fee revenues for hauled waste, including FOG, the local Hershey chocolate plant’s wastewater solids, and septage. When it began food waste codigestion in January 2017, it accepted high strength organic waste (HSOW) from food processing plants and Grind2Energy food scrap slurry for codigestion. It had decided it would not accept SSO food scraps, because it was not willing to take on the associated logistical challenges, including the difficulty and expense of debris separation. However, when Divert offered to supply a preprocessed food scrap slurry from its depackaging facility in Mechanicsburg (PA) that could go directly into DTMA’s blend tank, the Authority established a successful pilot in 2017, and signed a long-term nonbinding memorandum of understanding in 2018 to receive Divert slurries.

Oneida Water Pollution Control Plant

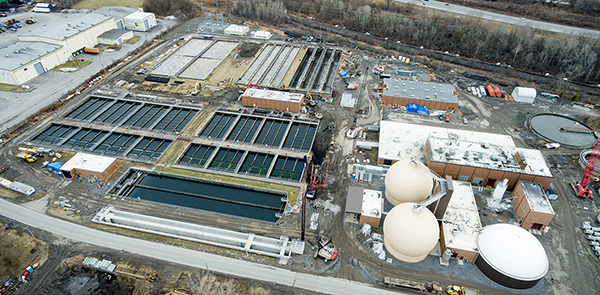

Oneida County WRRF, Utica, New York. New digesters in foreground (on right) and building housing food scrap processing system in background (upper left).

In upstate New York, the Oneida-Herkimer Solid Waste Authority (OHSWA) and the Oneida County Department of Water Quality and Water Pollution Control (Oneida County), with facilities across the street from one another in Utica, have partnered to create a Food2Energy program to divert food waste from landfill to AD. Oneida County’s 48 mgd Water Pollution Control Plant (WPCP) and sewerage system are undergoing a $380 million upgrade. Based on a long-term financial analysis, the utility decided to shift from incinerating its biosolids to digesting them and elected to add 10% to 12% capacity to its new digesters to accommodate codigestion. As part of the upgrade, the utility decommissioned its incinerators and constructed two new egg-shaped digesters, and a secondary digester with a gas holding structure. It also installed a new liquid receiving station, three 200-kW microturbines, and a biogas conditioning system.

Scott Equipment Thor Turbo Separator, in the OHSWA SSO Preprocessing Facility in their Eastern Transfer Station.

In 2019, OHSWA completed construction of a source separated organics (SSO) preprocessing facility with a Scott Equipment Thor Turbo Separator depackaging and separating system, enabling it to accept bagged and packaged SSO and send its slurry to the WPCP. The WPCP currently uses septage receiving station equipment to preprocess the food slurry before adding it to the blend tank. In a future component of the $380 million upgrade, the utility is planning to install SAVECO’s “The Beast,” which includes a drum screen and auger, to screen the slurry for contaminants.

Los Angeles County Sanitation Districts

The Los Angeles County (CA) Sanitation Districts (LACSD), a regional agency that operates under a Joint Administration Agreement with 24 special districts in the county, oversees wastewater treatment as well as solid waste disposal and recycling. LACSD’s flagship WRRF, the Joint Water Pollution Control Plant (JWPCP), is one of the largest in the United States, processing an average of 280 mgd dry weather flow. Following the success of a demonstration project with Waste Management delivery of its Engineered BioSlurry (EBS®) feedstock, in 2018 LACSD initiated a very large-scale codigestion program (with capacity up to 415 tons/day of food waste feedstocks). LACSD has been developing a diversified set of sources from private sector suppliers, as well as from its own food scrap preprocessing facility installed at its Puente Hills Materials Recovery Facility. The motivation for developing its own preprocessing facility was to provide an affordable recycling option for small- to medium-size hauling companies, which are less likely to have the capacity to invest in preprocessing equipment, so they could remain competitive in the organic waste management market. In late 2020, LACSD installed the first of two slurry receiving facilities at the JWPCP. A second one is in construction, and is expected to begin operating by April 2021.

The Sanitation Districts’ food scrap preprocessing facility installed at its Puente Hills Materials Recovery Facility provides an affordable outlet for small- to medium-scale haulers.

Carol Adaire Jones, an environmental economist, is a Visiting Scholar at the Environmental Law Institute (ELI) and coleads its Food Waste Initiative. She was the Principal Investigator on the WRF study.