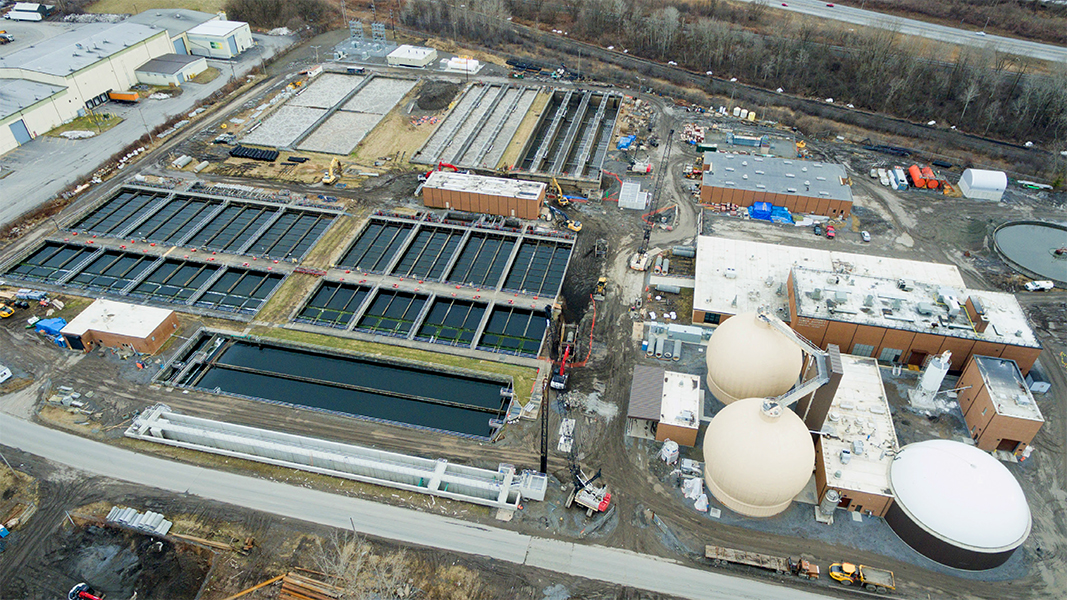

Top: Oneida County’s Water Pollution Control Plant (WPCP) with new egg-shaped digesters in foreground.

Carol Adaire Jones

In upstate New York, the Oneida-Herkimer Solid Waste Authority (OHSWA) and Oneida County Department of Water Quality and Water Pollution Control (Oneida County), with adjacent facilities in the city of Utica, have partnered to create a Food2Energy program to divert food waste from landfill to anaerobic digestion. The partnership was initiated prior to New York State enacting the Food Donation and Food Scrap Recycling Act in 2019. It provides a food scrap recycling option for generators, including the large generators of food scraps located within 25 miles of the facility (which includes most of Oneida and Herkimer Counties) covered under the new recycling mandate effective January 2022.

Oneida-Herkimer Solid Waste Authority’s source separated organics preprocessing facility is housed in this building, which is adjacent to the WPCP. Photos courtesy of OHSWA

The Oneida County Sewer District (OCSD), which is administered by the Water Quality and Water Pollution Control department, provides wastewater services for 110,000 residents in 15 municipalities, including the City of Utica. Oneida County’s Water Pollution Control Plant (WPCP) and sewerage system (33 million gallons/day (mgd) average daily flow) is undergoing a $380 million upgrade. Based on a long-term financial analysis conducted to inform the design of the upgrades, the utility decided to shift from incinerating its biosolids to treating them via anaerobic digestion, and add 10% to 12% capacity to its new digesters to accommodate codigestion. The biosolids are now disposed in OHSWA’s municipal solid waste (MSW) landfill.

OHSWA is a New York State public benefit corporation, created at the request of Oneida and Herkimer Counties in 1988 to provide sustainable solutions to solid waste management for the 75 communities in the two counties, including developing new facilities and programs for waste reduction and recycling. The Authority, which receives no financial support from the Counties, is funded primarily by facility tip fees, with additional revenues from the sale of recovered products (landfill gas, recyclables, compost), carbon and other environmental attribute credits, and grants.

The Food2Energy program launched in 2019, after construction was completed of a source separated organics (SSO) preprocessing facility at OHSWA, and new egg-shaped anaerobic digesters and a new liquid receiving station at the WPCP.

OHSWA Organics Management Strategy

In 2016, OHSWA — in partnership with Oneida County — initiated a feasibility study of codigestion of commercial SSO in the WPCP’s proposed new digesters. The Authority manages a yard trimmings compost facility that has insufficient capacity to expand to accept food scraps. The feasibility study determined that the scale of potential commercial SSO supply was sufficient to make preprocessing for codigestion economically feasible. OHSWA moved forward with commissioning the design and construction of a SSO processing facility in its Eastern Transfer Station, located in a property adjoining the WPCP. Construction was completed in 2019.

Commercial SSO arriving at the site is unloaded onto a sloped concrete tipping floor with a drain for inspection and removal of unprocessible items. The SSO is then loaded into a Scott THOR Turbo Separator, which reduces particle size and separates out packaging and other contaminants. Gray water from the WPCP is added to aid in emulsification of the slurry. Throughput capacity of the THOR is 12 to 20 tons/hour. The processed SSO is pumped to a 7,000-gallon conical bottom mixing tank, which is continuously mixed to prevent settling. More gray water is added to dilute the slurry to a total solids (TS) content of 10%.

Currently the slurry is hauled across the street to the WPCP by truck. Construction of a force main connecting the two facilities to pipe the slurry underground is in the works. OHSWA also will be installing a meter to measure percent solids, in order to manage the addition of gray water to achieve the 10% TS target for the slurry to be pumped to the WPCP.

Generator Participation

Commercial SSO includes loads of food waste from supermarkets (top) and packaged goods from food manufacturers (above).

The feasibility study anticipated that participation in food scrap recycling would increase over time. The study estimated that an initial phase of the program could yield 5,000 tons/year of food waste from a combination of large generators currently using landfill disposal (and thus subject to the mandate), and smaller voluntary participants with sustainability commitments. Due to the uncertainties in projecting compliance and voluntary participation, the analysis for sizing equipment needs and assessing economic feasibility of the program included a sensitivity analysis over a range of SSO tons supplied, from 5,000 tons annually in the initial phase to 21,000 tons/year, the estimated maximum for currently available SSO.

OHSWA provides an economic incentive for generators to participate in the program by charging a tipping fee for SSO of $40/ton — a savings of $22 on the $62/ton tipping fee for MSW at its landfill. Currently around 15 large organics haulers are participating, transporting SSO to OHSWA from generators including Hannaford grocery stores, food manufacturing companies (e.g., Chobani and Hood), local colleges and some restaurants. Other generators have expressed interest in the program.

Over the 18 months from July 2019 through December 2020, OHSWA has received 4,300 tons of commercial SSO. Quantities from food manufacturing have been increasing during this period, as more facilities are being added to the SSO pickups. However, institutional food service organizations and restaurants have experienced reductions in business due to COVID-19, and many have postponed consideration of participation. When the impacts of COVID-19 on the food sector diminish, the Authority will concentrate on outreach and education to increase generator participation within the waste shed, including restaurants and others not subject to the mandate. As participation grows, the hauling costs will become more competitive, which will improve the economics for generators.

Financing The Infrastructure

Throughput capacity of the Scott THOR Turbo Separator is 12 to 20 tons/hour.

OHSWA has invested $3.7 million in the design and construction of the SSO preprocessing facility, including construction of a new building and installation of preprocessing equipment, storage tanks, and pumps. It received about $1.6 million in grants to cover portions of the capital costs from the New York State Department of Environmental Conservation (NYSDEC). The Authority paid for the rest of the project through its cash reserves.

The tip fee of $40/ton was set to cover the capital and building and equipment O&M costs of the SSO processing system. OHSWA has an integrated tip fee, where the higher tip fee for MSW at its landfill cross-subsidizes the recycling waste streams. The subsidies cover overhead costs of administration, outreach and public education, as well as the operating costs of traditional recycling (for which no tip fee is charged), and any operating losses from organics recycling. To date, the revenues from organics recycling are comparable to its capital and O&M costs.

Oneida County Codigestion And Energy Strategy

The Oneida County WPCP and sewerage system is undergoing the $380 million upgrade primarily to comply with a regulatory mandate to mitigate combined storm water and sanitary sewer overflows in the collection system. To accomplish this, the upgrades will increase peak design flow from 55 to 111 mgd. A 30-year financial analysis indicated an AD solution would have higher net returns than upgrading the WPCP biosolids incinerator. In addition to lower O&M costs, another advantage of AD would be to sidestep the increasing stringency of air quality regulations for incinerators. When evaluating its future needs for AD capacity, Oneida County incorporated the additional 10% to 12% volume for codigestion of SSO.

The incinerators were decommissioned in 2019, and two new egg-shaped digesters were constructed — along with a secondary digester with a gas holding structure and a liquid waste receiving station, situated in front of the digesters. The WPCP currently is using JWC “Honey Monster” septage receiving equipment at the station to preprocess the food slurry before adding it to the blend tank. Because the plans for the Food2Energy program had not gelled when the contracting occurred, the receiving capacity was designed for food processing residuals, such as dairy whey, as well as fats, oil and grease (FOG). In a subsequent construction project, the utility is planning to install a SAVECO “The Beast”, which includes a drum screen and auger, to screen the slurry for contaminants. When that occurs, the septage receiving station will be moved to the headworks of the plant.

Oneida County invested in a Unisons Solutions biogas conditioning system to remove siloxanes, moisture and hydrogen sulfide from the biogas, and three Capstone 200 kW microturbines and heat exchangers to recover energy from the biogas. The microturbines, produce electricity and generate heat used to heat the digester complex and the liquid receiving station. Plans include adding two more 200-kW microturbines to increase capacity from 600 kW to 1,000 kW within the next few years.

Operational And Financial Impacts

The WPCP has codigested about 5 million gallons of food slurry over the past 19 months (through February 2021). It does not accept fats, oils and grease (FOG) at this time. The plant has not experienced digester upsets during this period. Because codigestion started shortly after the digesters became operational, it is difficult to identify the benefits of adding food waste on biogas production. The county estimates that the 12% of feedstock from food slurry increases biogas by 20%. It does not have an estimate of the impact on biosolids production.

The investments supporting the Food2Energy program to date, including the three digesters, a new liquid receiving station, and three 200-kW microturbines, cost $30 million. The approximate cost for future investments include $1.9 million for two new 200-kW microturbines and heat exchangers and $330,000 to install the SAVECO preprocessing equipment designed for food waste slurry and FOG in the receiving station.

With a tipping fee of $.02/gallon, Oneida County has earned $100,000 in tip fees over the 19 months of codigestion. With the estimated increase in biogas from codigestion, it has produced an additional 959,000 kWh, for a cost savings of $63,000 in power purchases. The combined impact on net revenue is an additional $8,590/month. The plant was able to reduce labor costs with the shift from incineration to AD (by cutting the two 24/7 positions monitoring the incinerators); the addition of codigestion has not added appreciably to labor costs.

Oneida County is financing $348 million for the facility and sewer system upgrade program, primarily with low interest loans from the New York State Clean Water State Revolving Fund. In addition, the County has received a total of $32 million in grants for the project as a whole.

Carol Adaire Jones, an environmental economist, is a Visiting Scholar at the Environmental Law Institute (ELI) and coleads its Food Waste Initiative. She was the Principal Investigator on the Water Research Foundation (WRF) study, ”Food Waste Co-Digestion at Water Resource Recovery Facilities: Business Case Analysis.” This article is excerpted from an expanded and updated version (February 2021) of the profile of the Food2Energy Partnership between Oneida-Herkimer Solid Waste Authority (OHSWA) and Oneida County, NY in Appendix B of the WRF report.