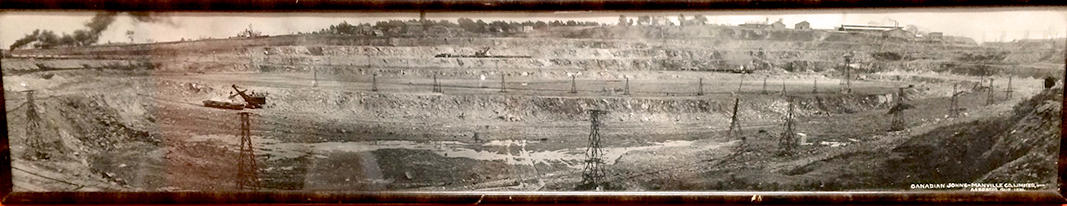

In addition to a successful mineland reclamation project, perhaps the best thing to happen in a town in Quebec (Canada) is a name change. In October 2020, the former town of Asbestos became the newly named town of Val des Sources. According to a recent update on the North East Biosolids & Residuals Association (NEBRA) website (from which this BioCycle Brief is excerpted), the town is home to the Jeffrey Mine, the world’s largest open-air chrysotile asbestos mine. Operations, mostly by the U. S. company Johns-Manville, began in the early 1900s and ended in 1983 as health concerns ended asbestos use. Since 2004, Englobe, a soils and residuals management company and NEBRA member, based in Sherbrooke, Quebec, has deployed nearly 400,000 tons of biosolids, paper mill residuals, some gypsum waste, and digestates that are blended in agronomic recipes to reclaim tailings rubble — barren rock piles and gravel that extend for miles. Over 500 acres have been revegetated, land that is now inhabited by wildlife, and used for parkland and recreation. The endeavor is named M.A.G.I.C. Land, or Making Asbestos Grow Impressive Conservation Land.

In addition to a successful mineland reclamation project, perhaps the best thing to happen in a town in Quebec (Canada) is a name change. In October 2020, the former town of Asbestos became the newly named town of Val des Sources. According to a recent update on the North East Biosolids & Residuals Association (NEBRA) website (from which this BioCycle Brief is excerpted), the town is home to the Jeffrey Mine, the world’s largest open-air chrysotile asbestos mine. Operations, mostly by the U. S. company Johns-Manville, began in the early 1900s and ended in 1983 as health concerns ended asbestos use. Since 2004, Englobe, a soils and residuals management company and NEBRA member, based in Sherbrooke, Quebec, has deployed nearly 400,000 tons of biosolids, paper mill residuals, some gypsum waste, and digestates that are blended in agronomic recipes to reclaim tailings rubble — barren rock piles and gravel that extend for miles. Over 500 acres have been revegetated, land that is now inhabited by wildlife, and used for parkland and recreation. The endeavor is named M.A.G.I.C. Land, or Making Asbestos Grow Impressive Conservation Land.

Gypsum residuals (foreground), wastewater biosolids (middle), and paper mill residuals (gray in back) are part of the soil mix used to restore native soil and plant ecosystems at mineland reclamation project in Val des Sources, QC. Photos courtesy of NEBRA

The project, which is ongoing, has included planting more than 12,000 trees and shrubs to jump start diverse ecology. Writes NEBRA, “This process of mine reclamation is not really magic. It requires a lengthy process of permitting (Quebec’s environment ministry strictly regulates all residuals and their uses); agronomic engineering of the soil mixes, followed by small-scale pilot testing of soils, seed mixes, and timing; construction of access roads and smoothing (to the extent possible) of the tailings; and, finally… mixing the bulk materials according to the final recipe, flinging and pushing the soil mix in a 10-inch layer over the rocky rubble, and seeding with the selected mix of grasses and legumes designed for quick growth and establishment of plant diversity over time.

“Throughout the process, regulations and Englobe’s own best management practices (BMPs) require ongoing testing and monitoring. For example, for the health and safety of its employees and area citizens, Englobe regularly tests for any airborne asbestos fibers that may be stirred up by its operations. (None have been detected.) Surface water and groundwater are monitored. And Englobe communicates routinely with Val des Sources town leaders and residents, ensuring ongoing understanding of the reclamation process.”

“Throughout the process, regulations and Englobe’s own best management practices (BMPs) require ongoing testing and monitoring. For example, for the health and safety of its employees and area citizens, Englobe regularly tests for any airborne asbestos fibers that may be stirred up by its operations. (None have been detected.) Surface water and groundwater are monitored. And Englobe communicates routinely with Val des Sources town leaders and residents, ensuring ongoing understanding of the reclamation process.”